All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

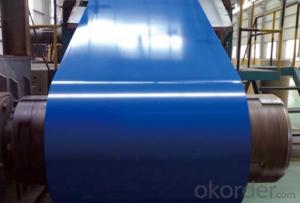

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is coil edge quality maintained in the production of HVAC components?

Coil edge quality is maintained in the production of HVAC components through various methods such as using precision machinery to cut and shape the coils, implementing quality control measures to ensure consistent dimensions and smooth edges, and utilizing specialized techniques like deburring or edge conditioning to remove any imperfections or sharp edges.

What is the role of edge conditioning in producing high-quality metal building materials?

The role of edge conditioning in producing high-quality metal building materials is to enhance the structural integrity and aesthetic appeal of the finished product. By carefully removing burrs, sharp edges, and irregularities from the edges of metal sheets or components, edge conditioning ensures a smooth, precise, and safe surface. This process not only improves the overall appearance of the materials but also facilitates easier handling, assembly, and installation, ultimately contributing to the durability and reliability of the metal building.

What is the purpose of slitting in steel coil processing?

The purpose of slitting in steel coil processing is to cut wide coils of steel into narrower strips of specific widths, which are often used for various industrial applications. This process allows for more efficient handling, transportation, and utilization of the steel material, as well as the ability to meet specific customer requirements for width.

Wholesale Steel Coils from supplier in Mali

We are a Steel Coils supplier serving the Mali, mainly engaged in the sale, quotation, and technical support services of various Steel Coils products in the Mali region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Steel Coils procurement services in the Mali. Not only do we have a wide range of Steel Coils products, but after years of market development in the Mali, we can also provide valuable experience for your projects.