Grade AISI 304_304L Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade AISI 304_304L Stainless Steel Round Bar in stock

Descriptio of Grade AISI 304_304L Steel Round Bar in Stock

(stainless steel round bar, angle bar , flat bar , channel bar , hexagon bar , square bar .)

1.grade:201,202,301,302,303,304,304L,308,309,310,310S,316,316L,321,410,420,430,etc.

2.diameter:3mm-400mm.

3.surface:bright , black , pickeled & bright .

4.length: no more than 6 m .

5.packing: according to international standards of export .

6.trade terms: FOBshanghai , CIF+import port .

7.payment terms: L/C at sight , 30% T/T in advance + copy of B/L .

8.delivery time: within 8 to 12 days since the receipt of payment .

9. MOQ is 1 ton .

Description of Grade AISI 304_304L Steel Round Bar in Stock

Standard | AISI , JIS , ER , GB , ASTM , etc. |

| Grade | 201,201,301,302,303,304,304l,308,309,310,310S,316,316L,321,410,420,etc. |

| Application | widely used in the areas as ss fasteners , chains , kitchen and sanitary wares , furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc. with a high strength after cold-drawn , anti-stress corrosion , good surface . |

| Chemcial composition | according to international standards of ASTM , AISI , JIS , ER , GB ,etc. |

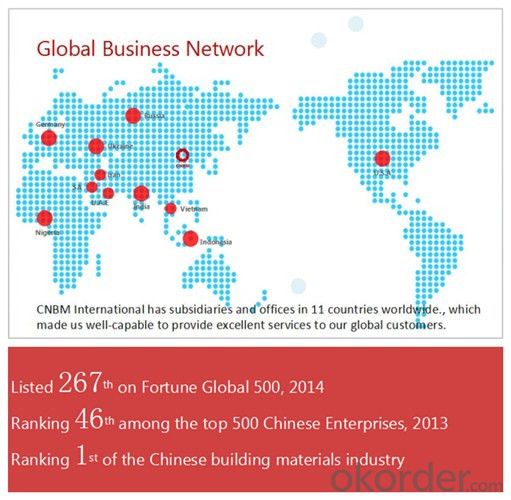

Company Information of Grade AISI 304_304L Steel Round Bar in Stock

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Grade AISI 304_304L Steel Round Bar in Stock

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the properties of alloy steel?

- Alloy steel possesses a combination of properties that make it highly versatile and desirable in various applications. It exhibits enhanced strength, hardness, and wear resistance due to the addition of alloying elements such as chromium, nickel, and molybdenum. Alloy steel can withstand high temperatures, making it suitable for use in elevated temperature environments. It also offers excellent corrosion resistance and is highly durable, making it ideal for applications that require long-term reliability. Additionally, alloy steel can be easily machined and fabricated, further adding to its appeal in various industries.

- Q: How is special steel produced?

- Special steel is typically produced through a combination of several processes, including melting, refining, casting, and heat treatment. It involves carefully selecting and blending various alloying elements to achieve desired chemical and mechanical properties. These elements are added to molten steel, which is then refined to remove impurities. The refined steel is then cast into various shapes and forms, such as bars, sheets, or tubes. Finally, the steel undergoes heat treatment processes like tempering or quenching to further enhance its strength and other properties.

- Q: What are the effects of different heat treatment processes on special steel?

- Different heat treatment processes have varying effects on special steel. Annealing, for example, helps to soften the steel and increase its ductility, making it easier to shape and work with. Hardening processes, such as quenching and tempering, increase the steel's hardness and strength, making it suitable for applications that require toughness and resistance to wear. Tempering, on the other hand, reduces the hardness of the steel while increasing its toughness. Additionally, heat treatment processes can also influence the steel's internal structure, such as the size and distribution of grains, which in turn affects its mechanical properties. Overall, the choice of heat treatment process can significantly impact the final characteristics of special steel, allowing for customization to meet specific performance requirements.

- Q: How does the carbon content affect the properties of special steel?

- The carbon content in special steel plays a crucial role in determining its properties. The addition of carbon to steel alters its microstructure and influences various mechanical and physical properties. The primary effect of carbon content is on the hardness and strength of the steel. Increasing the carbon content in special steel leads to an increase in its hardness. This is because carbon atoms occupy the interstitial sites in the iron lattice, which creates a distortion in the crystal structure, making it more resistant to deformation. Higher carbon content also results in a greater martensitic transformation during heat treatment, which further enhances the hardness of the material. Furthermore, the strength of special steel is significantly influenced by carbon content. Higher carbon levels lead to increased strength due to the formation of stronger and more numerous carbide precipitates. These carbides act as obstacles to dislocation movement, making it more difficult for the steel to deform under load. However, it is important to note that the increase in carbon content also comes with some trade-offs. As the carbon content rises, the ductility of the steel decreases. This means that the material becomes less able to deform without fracturing. High carbon content can make the steel brittle, reducing its toughness and impact resistance. In addition to hardness and strength, carbon content affects other properties of special steel. It influences the steel's wear resistance, as higher carbon content leads to the formation of harder carbides that can resist wear and abrasion. Carbon also affects the steel's machinability, with higher carbon content making the material more difficult to machine due to increased hardness. In conclusion, the carbon content has a significant impact on the properties of special steel. It affects the hardness, strength, ductility, toughness, wear resistance, and machinability of the material. Therefore, careful consideration of the desired properties and application requirements is necessary when determining the appropriate carbon content for special steel.

- Q: How does nitriding improve the wear resistance of special steel?

- The wear resistance of special steel is greatly enhanced through the process of nitriding, which involves infusing nitrogen atoms into the steel's surface to create a hardened layer known as nitride. This nitride layer is extremely tough and can withstand abrasive forces and friction, thereby increasing the steel's durability. The enhanced wear resistance of nitrided special steel can be attributed primarily to the formation of iron nitride (Fe3N) within the nitride layer. Iron nitride possesses a high level of hardness, typically ranging from 800 to 1000 HV (Vickers hardness), which is significantly greater than the hardness of the steel's base material. This contributes to the improved wear resistance. Moreover, the nitride layer formed during nitriding also augments the surface hardness of the steel, rendering it more resistant to deformation and indentation, which are common causes of wear in materials subjected to friction and abrasion. In addition, the nitride layer acts as a protective barrier, safeguarding the underlying steel against chemical reactions, oxidation, and corrosion. This barrier prevents the steel from deteriorating when exposed to harsh environments, moisture, and chemicals, thereby further enhancing its wear resistance. Ultimately, the process of nitriding enhances the wear resistance of special steel by creating a hardened nitride layer that is both exceptionally hard and resistant to wear, while also serving as a protective barrier. Consequently, the lifespan and durability of the steel are significantly prolonged, making it an ideal choice for applications that require high wear resistance, such as cutting tools, gears, and automotive components.

- Q: What are the different methods of preventing hydrogen embrittlement in special steel?

- There are several methods that can be employed to prevent hydrogen embrittlement in special steel. These include proper material selection, such as using low-hydrogen alloys or stainless steel grades that are less susceptible to embrittlement. Additionally, controlling the environment during manufacturing and storage processes is crucial, as hydrogen absorption can occur during these stages. Other preventive measures include heat treatment processes like stress relieving and tempering, which can help reduce internal stresses and enhance the steel's resistance to embrittlement. Overall, a combination of careful material selection, controlled environments, and appropriate heat treatment techniques can effectively prevent hydrogen embrittlement in special steel.

- Q: How does maraging steel achieve high strength through aging?

- Maraging steel achieves high strength through a process called aging, which involves heating the steel at a specific temperature for a specific duration. During aging, the alloying elements in maraging steel precipitate into fine particles, creating a strengthening effect. This process enhances the steel's hardness, tensile strength, and resistance to deformation, resulting in its high strength properties.

- Q: How is special steel used in the production of pressure vessels?

- Special steel is used in the production of pressure vessels due to its unique properties that make it suitable for withstanding high pressure environments. Pressure vessels are containers designed to hold gases or liquids at a pressure significantly different from the surrounding atmosphere. These vessels are commonly used in industries such as oil and gas, chemical, and power generation. The use of special steel in pressure vessel production is crucial to ensure the safety and reliability of these containers. Special steels, such as carbon steels, stainless steels, and alloy steels, offer enhanced mechanical properties, high strength, and excellent corrosion resistance. These properties are essential for withstanding the extreme pressure conditions experienced by pressure vessels. One of the primary functions of special steel in pressure vessel production is to provide resistance against internal pressure. The steel needs to be able to withstand the force exerted by the contents of the vessel without deforming or rupturing. The high strength and toughness of special steels make them capable of handling these pressures, ensuring the integrity of the vessel and preventing catastrophic failures. Special steel also plays a vital role in maintaining the structural integrity of pressure vessels. These vessels are subjected to various external loads, such as wind, seismic forces, and thermal expansion. The superior mechanical properties of special steel enable it to bear these loads without significant deformation or failure, ensuring the structural stability of the pressure vessel. Furthermore, special steel's resistance to corrosion is essential in the production of pressure vessels. Pressure vessels often contain corrosive substances, and the corrosive environment can lead to the degradation of the material over time. Special steels, especially stainless steels, offer excellent resistance to corrosion, minimizing the risk of material deterioration and maintaining the vessel's longevity. In summary, special steel is used in the production of pressure vessels due to its high strength, toughness, and corrosion resistance. These properties enable the steel to withstand high pressure conditions, maintain structural integrity, and prevent corrosion-related failures. By utilizing special steel, pressure vessel manufacturers can ensure the safety, reliability, and longevity of these critical containers.

- Q: Can special steel be used in the production of turbine blades?

- Yes, special steel can be used in the production of turbine blades. Special steel alloys, such as nickel-based superalloys, are commonly used due to their high strength, heat resistance, and excellent corrosion resistance, making them suitable for the demanding conditions and extreme temperatures experienced in turbine engines.

- Q: Can special steel be used for jewelry?

- Yes, special steel can be used for jewelry. Special steel, such as stainless steel or titanium, is often used in jewelry making due to its durability, resistance to tarnish and corrosion, and its hypoallergenic properties. It can be crafted into various designs and finishes, offering a stylish and affordable alternative to traditional precious metals like gold or silver.

Send your message to us

Grade AISI 304_304L Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords