Grade ASTM A36 Round Steel Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

High Quality A36 Round Steel Bar Large Quantity in Stock

Specifications of High Quality A36 Round Steel Bar Large Quantity in Stock

1.Competitive price

2.Prime quality

3.Best service

4.Quick deliver time

5 BV ,SGS third party inspection

Description of High Quality A36 Round Steel Bar Large Quantity in Stock

Description | Carbon Steel Rod/Carbon Steel Bar,carbon steel rod,carbon steel shaft,mild steel bar, mild steel shaft,ms bar | |

| Material | ASTM | 1005,1006,1008,1010,1015,1020,1025,1030,1035,1040,1045,1050,1055,1060,1065,1070,1080,1084,1016,1022 |

| DIN | Ck10,Ck15,Ck22,Ck25,Ck30,Ck35, Ck40,Ck45,Ck50, 30Mn4,40Mn4 | |

| BS | 040A04,095M15,045M10,080A40,045M10,080M50 | |

| Standard | GB/T799,ASTM A29,A108,A321,A575,BS970,DIN1652,JIS G4051 | |

| Section shape | Round,square,hexagonal,flat,angle | |

| Surface | Black painted,galvanized | |

| Specifications | Round bar | Diameter: 4mm~800mm |

| Angle bar | Size: 3mm*20mm*20mm~ 12mm*800mm*800mm | |

| Square bar | Size: 4mm*4mm~100mm*100mm | |

| Flat bar | Thickness: 2mm~100mm | |

| Width:10mm~500mm | ||

| Hexagonal | Size: 4mm~800mm | |

| Length | 2m,4m,5.8m,6m,11.8m,12m or as required. | |

| Trade terms | Payment terms | T/T,L/C,Western Union |

| Price terms | FOB,CIF,CFR,EXW | |

| Package | Bundled,wooden box for export standard package. | |

| Delivery Date | Normally according to the order quantity | |

| Application | Carbon steel rod applies to chemical industry, shipping industry, manufacturing industry,construction,decorate Industry,electric power,pump shafts, sanitary wares,furniture handles,boiler,high temperature resistant,low temperature resistant, corrosion resistant. | |

Company Introduction of High Quality A36 Round Steel Bar Large Quantity in Stock

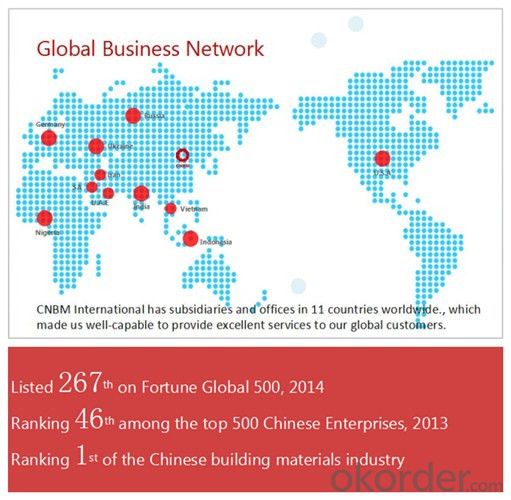

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of High Quality A36 Round Steel Bar Large Quantity in Stock

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel contribute to the power generation machinery industry?

- The power generation machinery industry greatly benefits from the use of special steel, which plays a vital role in improving the efficiency, reliability, and durability of power generation equipment. To begin with, special steel possesses remarkable mechanical properties, including high strength, toughness, and temperature resistance. These properties make it an excellent choice for manufacturing essential components of power generation machinery, such as turbines, generators, and boilers. The outstanding strength and toughness of special steel enable these components to withstand extreme pressures, temperatures, and harsh operating conditions, guaranteeing the safe and efficient functioning of power plants. Furthermore, special steel alloys can be specifically engineered to resist corrosion, erosion, and wear, which are common challenges faced by power generation equipment. Corrosion occurs due to chemical reactions between metals and the environment, while erosion and wear result from the high-speed flow of steam, water, or gases. By utilizing corrosion-resistant and wear-resistant special steel, power generation machinery can operate for extended periods without significant deterioration, thereby reducing maintenance needs and downtime. Another significant contribution of special steel to the power generation machinery industry is its ability to retain magnetic properties at high temperatures. This is particularly crucial for electrical generators, as it ensures optimal performance and efficiency. Special steel with excellent magnetic properties enables generators to produce electricity with minimal energy losses caused by heat, resulting in increased power output and reduced energy consumption. Moreover, the design flexibility of special steel allows for the production of customized components tailored to the specific requirements of various power generation technologies. For instance, in nuclear power plants, special steel alloys with high resistance to radiation and neutron embrittlement are used for constructing reactor pressure vessels and other critical components. In renewable energy systems like wind turbines, special steel with superior fatigue resistance is utilized to withstand the cyclic loading experienced by turbine blades. In conclusion, special steel plays a crucial role in the power generation machinery industry by improving the efficiency, reliability, and durability of power generation equipment. Its exceptional mechanical properties, corrosion resistance, wear resistance, magnetic properties, and design flexibility make it indispensable for manufacturing components capable of withstanding extreme conditions and ensuring the continuous and efficient generation of electricity.

- Q: What are the main applications of special steel in the agricultural sector?

- Special steel has various applications in the agricultural sector, including the manufacturing of agricultural machinery and equipment such as tractors, plows, and harvesters. It is also used for constructing storage silos, irrigation systems, and fencing materials. Additionally, special steel is utilized in the fabrication of cutting tools, blades, and parts for farming implements, ensuring durability and high performance in challenging agricultural environments.

- Q: What are the benefits of using special steel in the energy sector?

- Using special steel in the energy sector comes with various advantages. To begin with, special steel provides exceptional strength and durability, making it the ideal material for constructing different energy infrastructure components like pipelines, pressure vessels, and turbines. Its high tensile strength and resistance to corrosion ensure that these structures can withstand the harsh conditions and pressures encountered in the energy sector, thereby reducing the risk of failures and increasing their lifespan. Additionally, special steel exhibits excellent heat resistance properties, which is crucial in the energy sector where high temperatures are generated. This makes it suitable for applications such as power generation, where it can be used in the construction of boilers, heat exchangers, and nuclear reactors. The ability of special steel to withstand extreme heat without deforming or losing its mechanical properties is vital for ensuring the safe and efficient operation of energy facilities. Furthermore, special steel offers superior weldability and formability, allowing for easier fabrication and assembly of complex energy infrastructure components. This makes it easier and more cost-effective to manufacture and install equipment in the energy sector, reducing both production costs and construction time. Another advantage of using special steel in the energy sector is its resistance to fatigue and cracking. Energy infrastructure components are subjected to cyclic loading and stress, which can lead to fatigue failure over time. The ability of special steel to resist fatigue and crack propagation ensures the long-term reliability and safety of energy infrastructure. Moreover, special steel offers excellent magnetic properties, making it suitable for use in power transmission and electrical equipment. Its magnetic permeability and low electrical resistance allow for efficient transmission and distribution of electricity, reducing energy losses and improving overall system performance. In conclusion, the use of special steel in the energy sector provides enhanced strength, durability, heat resistance, weldability, and fatigue resistance. These properties contribute to the reliability, safety, and efficiency of energy infrastructure, making special steel an invaluable material for the energy sector.

- Q: How is alloy steel used in the production of gears and shafts?

- Alloy steel is commonly used in the production of gears and shafts due to its high strength, durability, and resistance to wear and fatigue. The addition of various alloying elements, such as chromium, nickel, and molybdenum, enhances the material's mechanical properties, making it suitable for heavy-duty applications. Alloy steel gears and shafts can withstand high loads, transmit torque efficiently, and provide reliable performance, ensuring smooth operation and prolonged lifespan in various industries, including automotive, aerospace, and manufacturing.

- Q: What are the different quenching techniques used for special steel?

- There are several different quenching techniques used for special steel, including oil quenching, water quenching, and air quenching. Oil quenching involves immersing the steel in oil to rapidly cool it and achieve the desired hardness. Water quenching is a more aggressive technique, where the steel is submerged in water to achieve even faster cooling and increased hardness. Air quenching, on the other hand, involves allowing the steel to cool in ambient air, resulting in a slower cooling rate and less hardness. Each technique has its own advantages and is chosen based on the specific requirements of the steel being quenched.

- Q: What are the main characteristics of magnetic steel forgings?

- Magnetic steel forgings exhibit several key characteristics that make them highly desirable in various industries. Firstly, magnetic steel forgings possess excellent magnetic properties, allowing them to be easily magnetized and demagnetized. This property makes them suitable for applications where magnetism is required, such as in electrical motors and generators. Secondly, magnetic steel forgings possess high strength and durability. Due to the forging process, the steel is compressed and shaped, resulting in a dense and uniform microstructure. This enhances the mechanical properties of the steel, including its tensile strength, impact resistance, and fatigue strength. As a result, magnetic steel forgings can withstand heavy loads and harsh operating conditions, making them ideal for use in demanding applications such as automotive components, industrial machinery, and aerospace parts. Another characteristic of magnetic steel forgings is their excellent corrosion resistance. The forging process helps to refine the grain structure of the steel, making it less susceptible to corrosion and oxidation. This property is crucial in industries where components are exposed to corrosive environments or high temperatures, such as marine applications or oil and gas equipment. Furthermore, magnetic steel forgings offer good machinability and weldability. The forging process not only enhances the mechanical properties of the steel but also improves its machinability, allowing it to be easily shaped and modified into intricate designs. Additionally, magnetic steel forgings can be readily welded without compromising their integrity, providing flexibility in manufacturing and assembly processes. Lastly, magnetic steel forgings exhibit excellent dimensional stability. The forging process involves controlled heating and cooling, which helps to minimize dimensional changes and distortions. This ensures that the final product maintains its shape and dimensions, enabling precise fit and compatibility with other components. In summary, the main characteristics of magnetic steel forgings include excellent magnetic properties, high strength and durability, corrosion resistance, good machinability and weldability, and dimensional stability. These characteristics make magnetic steel forgings highly versatile and widely used in various industries, contributing to their overall success and popularity.

- Q: How is special steel used in the defense supply chain?

- Special steel is used in the defense supply chain for a variety of applications, including the manufacturing of military vehicles, weaponry, and protective gear. Its high strength, durability, and resistance to extreme conditions make it ideal for ensuring the safety and effectiveness of defense equipment in combat situations.

- Q: How does the microstructure of special steel affect its performance?

- The microstructure of special steel plays a significant role in determining its performance. Special steels are alloyed with specific elements to enhance their properties and meet specific application requirements. The microstructure refers to the arrangement of the steel's crystalline grains and the presence of any phase transformations within the material. One critical aspect of the microstructure is the grain size. Fine-grained structures, achieved through controlled cooling or alloying additions, offer improved strength, hardness, and toughness. Smaller grain sizes hinder the movement of dislocations within the material, resulting in increased strength and hardness. This is particularly crucial in applications that require high strength-to-weight ratios, such as aerospace or automotive components. Another crucial factor is the presence of various phases in the microstructure. The addition of specific alloying elements can promote the formation of different phases, such as martensite, bainite, or ferrite. These phases have different mechanical properties, such as hardness, toughness, and corrosion resistance. By carefully controlling the microstructure, it is possible to tailor the steel's performance to specific applications. For example, martensitic structures offer high hardness and wear resistance, ideal for cutting tools, while bainitic structures provide a good balance of strength and toughness, suitable for structural components. Furthermore, the microstructure also governs the steel's response to heat treatment processes, such as quenching and tempering. Heat treatments can modify the microstructure to achieve desired mechanical properties, such as increasing hardness or improving resistance to fatigue. The microstructure's ability to transform during heat treatment allows for precise control over the steel's performance characteristics. In summary, the microstructure of special steel significantly affects its performance. Grain size, phase distribution, and response to heat treatment are all key factors that determine the steel's mechanical properties and suitability for specific applications. By understanding and manipulating the microstructure, engineers can design special steels with enhanced performance, meeting the stringent demands of various industries.

- Q: What are the main characteristics of magnetic steel?

- Magnetic steel, also referred to as ferromagnetic steel, possesses several essential features that render it highly suitable for a wide range of industrial applications. Firstly, magnetic steel demonstrates a robust magnetic field, enabling it to attract and retain magnetic materials. This quality plays a vital role in the production of electrical devices like motors, transformers, and generators, where the steel is utilized to establish magnetic circuits and enhance the efficiency of electromagnetic processes. Another significant aspect of magnetic steel is its high saturation magnetization, indicating its ability to reach maximum magnetic flux density under a given magnetic field strength. This attribute guarantees that magnetic steel can maintain a powerful magnetic field even when subjected to external forces or fluctuations in the magnetic field. Such stability and reliability render it ideal for applications that demand consistent magnetic performance. Moreover, magnetic steel exhibits exceptional electrical conductivity, which is of utmost importance in applications where the steel serves as a core material for electrical circuits. The superior electrical conductivity of magnetic steel minimizes energy losses and facilitates effective power transmission and distribution. Additionally, magnetic steel possesses a high coercivity, which denotes its capability to resist demagnetization. This characteristic is crucial in applications where the steel is exposed to fluctuating magnetic fields or mechanical stresses, as it ensures the long-term stability of its magnetic properties. In summary, the principal characteristics of magnetic steel encompass a strong magnetic field, high saturation magnetization, excellent electrical conductivity, and high coercivity. These properties establish magnetic steel as an indispensable material in various industries, including electrical engineering, power generation, and magnetic product manufacturing.

- Q: What are the applications of high-strength low-alloy (HSLA) steel?

- High-strength low-alloy (HSLA) steel finds applications in various industries such as automotive, construction, and manufacturing. It is commonly used in the production of lightweight and durable vehicle components, structural beams, pipelines, and machinery parts. HSLA steel's enhanced strength and toughness make it ideal for applications where weight reduction, increased load-bearing capacity, and resistance to corrosion and impact are crucial.

Send your message to us

Grade ASTM A36 Round Steel Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords