Stainless steel sheet 304/304L,202,310S,316L,316Ti,410,420

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

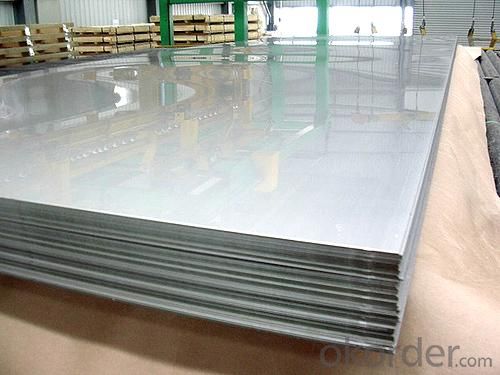

Stainless steel plate/sheet

304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

| Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

| Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

| Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

| Packaging | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

| Quality | No.1 |

| Productivity | 1200ton/day |

| Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |

Product Shows :

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Packaging and Loading

- Q: What are the factors to consider when selecting the right grade of stainless steel sheet?

- When selecting the right grade of stainless steel sheet, there are several important factors to consider. These include the intended application and environment, desired corrosion resistance, strength requirements, temperature resistance, and budget constraints. Additionally, factors like fabrication ease, availability, and aesthetic preferences should also be taken into account. Ultimately, it is crucial to carefully evaluate these factors in order to choose the most suitable grade of stainless steel sheet for your specific needs.

- Q: What are the benefits of using textured stainless steel sheets?

- There are several benefits of using textured stainless steel sheets. Firstly, the textured surface adds an aesthetic appeal to any space, giving it a unique and modern look. Secondly, the texture helps to hide fingerprints, smudges, and scratches, making it easier to maintain and clean. Additionally, the texture provides better grip and slip resistance, making it suitable for applications where safety is a concern, such as stairs or outdoor surfaces. Moreover, stainless steel is highly durable, corrosion-resistant, and hygienic, making it suitable for various industries, including food preparation, medical, and architectural.

- Q: Are stainless steel sheets suitable for wastewater treatment plants?

- Yes, stainless steel sheets are suitable for wastewater treatment plants. Stainless steel is known for its corrosion resistance, making it an excellent choice for environments with high moisture and chemical exposure, such as wastewater treatment plants. It can withstand the harsh conditions and provide long-lasting durability. Additionally, stainless steel is easy to clean and maintain, which is essential in a wastewater treatment facility where cleanliness and hygiene are critical. The material also has a high strength-to-weight ratio, making it suitable for various applications within the plant, such as tanks, piping, and equipment. Overall, stainless steel sheets are a reliable and practical choice for wastewater treatment plants.

- Q: Stainless steel plate glued to tiles, what glue?

- Depending on the size of the material and the number of adhesive areas, you can choose a different glue, the same function of glue, you should compare the quality and price of glue. Before you recommend what glue to use, you should first identify the following questions to choose the right glue.

- Q: Can stainless steel sheets be used for brewery piping?

- Yes, stainless steel sheets can be used for brewery piping. Stainless steel is a common material choice for brewery piping due to its corrosion resistance, durability, and hygienic properties. It can withstand the harsh conditions and high temperatures associated with the brewing process, making it an ideal material for brewery piping systems.

- Q: Are stainless steel sheets suitable for power plant equipment?

- Yes, stainless steel sheets are suitable for power plant equipment. Stainless steel is known for its excellent corrosion resistance, high strength, and durability, making it a popular choice for various industries, including power plants. Power plants often have harsh environments with high temperatures, pressure, and corrosive elements, and stainless steel can withstand these conditions effectively. It also has good heat resistance and can maintain its structural integrity at elevated temperatures, which is crucial for power plant equipment. Additionally, stainless steel sheets can be easily fabricated and welded to meet specific design requirements for power plant equipment, making them a versatile and reliable choice.

- Q: Are stainless steel sheets good for exhaust systems?

- Indeed, exhaust systems greatly benefit from the utilization of stainless steel sheets. Renowned for their remarkable resistance to corrosion, heat, and pressure, stainless steel stands as a widely favored option for exhaust system materials. Its ability to endure the rigors of extreme temperatures and harsh conditions guarantees durability and longevity. Furthermore, stainless steel exhibits exceptional acoustic properties, contributing to the reduction of noise levels. Moreover, the malleability and weldability of stainless steel sheets enable the fabrication of tailored exhaust system designs. In summary, stainless steel sheets serve as a dependable and effective material for exhaust systems, excelling in terms of performance, aesthetics, and overall functionality.

- Q: What are the different types of surface finishes for stainless steel sheets?

- There are several different types of surface finishes for stainless steel sheets, including brushed, mirror, embossed, bead blasted, and satin.

- Q: What is the fire resistance rating of stainless steel sheets?

- Stainless steel sheets typically do not have a fire resistance rating on their own as they are not inherently fire resistant materials. However, stainless steel can exhibit good fire resistance properties due to its high melting point and low thermal conductivity. This means that stainless steel sheets are less likely to melt or transfer heat during a fire, which can help to prevent the spread of flames. Additionally, stainless steel is also corrosion resistant, which can further enhance its performance in fire situations. However, it is important to note that the fire resistance of a structure or system is determined by a combination of various factors, including the overall design, construction, and use of fire-resistant materials. Therefore, the fire resistance rating of stainless steel sheets may vary depending on the specific application and the overall fire protection measures in place.

- Q: What's the difference between stainless steel hot rolling and cold rolling?

- Cold rolling: it is rolled and rolled on the basis of hot rolled stainless steel plate and coil. Generally speaking, it is the process of hot rolling, pickling and cold rolling. Although the rolling process also causes the steel plate to heat up during the process, it is called cold rolling. Because of the cold rolling of continuous hot rolling, the mechanical properties are poor and the hardness is too high. It must be annealed to restore its mechanical properties. Rolled rolls are generally used to make products without bending or stretching.

Send your message to us

Stainless steel sheet 304/304L,202,310S,316L,316Ti,410,420

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords