Stainless steel plate/sheet 304,201,202,310S,316L,316Ti,304L,410,420,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

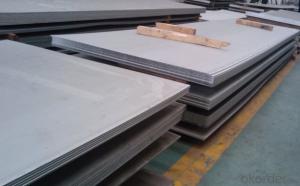

Stainless steel plate/sheet

304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

| Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

| Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

| Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

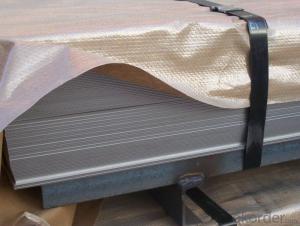

| Packaging | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

| Quality | No.1 |

| Productivity | 1200ton/day |

| Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |

Product Shows :

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Packaging and Loading

- Q:What is the composition of stainless steel sheets?

- Stainless steel sheets are primarily composed of iron, chromium, and varying amounts of other elements such as nickel, manganese, and carbon. The main component, iron, provides the strength and durability of the sheets, while chromium is added to enhance corrosion resistance. The addition of nickel increases the sheets' resistance to high temperatures and improves their overall mechanical properties. Manganese is added to enhance the sheets' formability, and carbon is added to improve their hardness. These elements work together to create a versatile and highly reliable material that is commonly used in various industries, including construction, automotive, and manufacturing.

- Q:How long do stainless steel sheets last?

- Stainless steel sheets are renowned for their durability and long-lasting nature. The lifespan of these sheets can vary depending on factors like the grade and quality of the stainless steel, environmental conditions, and maintenance practices. However, with proper care and normal circumstances, stainless steel sheets can endure for many decades or even a lifetime. The longevity of stainless steel is greatly influenced by its ability to resist corrosion. This is made possible by the presence of chromium, which forms a passive layer on the surface of the material, safeguarding it from rust and corrosion. This natural protective layer enables stainless steel sheets to withstand harsh environmental conditions, including exposure to moisture, chemicals, and extreme temperatures. Moreover, the grade of stainless steel also plays a role in its lifespan. There are different grades available, such as 304, 316, and 430, each offering varying levels of corrosion resistance. Higher grades, particularly 316 stainless steel, exhibit greater resistance to corrosion and are commonly used in marine and highly corrosive environments, ensuring a longer lifespan. To maximize the lifespan of stainless steel sheets, proper maintenance is crucial. Regular cleaning with mild detergents and non-abrasive materials is necessary to eliminate dirt, grime, and contaminants that can degrade the protective layer of stainless steel. Additionally, it is important to avoid contact with harsh chemicals or abrasive materials that can scratch or damage the surface. While stainless steel sheets have an impressive lifespan, it is important to acknowledge that their durability is not limitless. Over time, factors like wear and tear, exposure to severe conditions, or improper maintenance can gradually diminish the protective layer of stainless steel and reduce its lifespan. Nonetheless, with appropriate care and maintenance, stainless steel sheets can be a cost-effective and enduring choice for various applications, including construction, automotive, and household products.

- Q:What is the maximum temperature stainless steel sheets can withstand?

- The specific grade of stainless steel determines the maximum temperature that stainless steel sheets can endure. Typically, most stainless steel grades can handle temperatures up to approximately 1500°F (815°C) without significant oxidation or scaling. Nevertheless, some high-temperature stainless steel grades like 310 or 321 can endure temperatures up to 2100°F (1150°C) or even higher. To guarantee optimal performance and durability, it is crucial to consider the specific application and grade of stainless steel when determining its maximum temperature resistance.

- Q:What are the different types of surface treatments available for stainless steel sheets?

- There is a variety of surface treatments accessible for stainless steel sheets, each with its own purpose and distinct advantages. 1. The Mill Finish is the most basic type of surface treatment, achieved directly from the mill after the stainless steel sheet's manufacturing process. It presents a smooth, dull appearance and is commonly utilized for a clean, unembellished look. 2. The Brushed Finish, also known as satin finish, entails brushing the stainless steel surface with a fine abrasive substance to create fine parallel lines. This finish offers a decorative, textured appearance while concealing any surface imperfections or scratches. 3. The Mirror Finish creates a highly reflective surface resembling a mirror. It is attained by progressively polishing the stainless steel sheet with finer abrasives until a glossy, reflective finish is achieved. This finish is commonly used in decorative applications where a high level of shine is desired. 4. The Bead Blasted Finish involves blasting the stainless steel surface with tiny glass beads at high pressure. This creates a uniform, matte texture with a slightly rough feel. The bead blasted finish is often employed in architectural applications to achieve a modern, industrial appearance. 5. The Etched Finish involves applying an acid or chemical solution to the stainless steel surface to form intricate patterns or designs. This treatment allows for a high level of customization and is commonly used in architectural, signage, and decorative applications. 6. PVD Coating, or Physical Vapor Deposition, is a process where a thin film of a specific material is deposited onto the stainless steel surface using a vacuum chamber. This coating can provide various colors and finishes, such as gold, black, or bronze, while also enhancing the durability and corrosion resistance of the stainless steel sheet. These examples represent only a fraction of the diverse surface treatments available for stainless steel sheets. The choice of treatment depends on the desired aesthetic, functionality, and application requirements.

- Q:What welding equipment do we need for welding stainless steel sheet and stainless steel square tube?

- 1 mm thick enough, basically argon arc welding machine can, 0.2 thick stainless steel plate welding is not good ah, how have three or four points it can be positive or negative, only a few joints only, mainly to see the technology myself you, not what, the polishing wheel is on the line let's do it, you can buy a good quality of argon arc welding machine, the high price of the arc is stable

- Q:What are stainless steel sheets used for?

- Stainless steel sheets are commonly used in various industries and applications, including construction, automotive, aerospace, food processing, and medical equipment manufacturing. They are primarily utilized for their exceptional resistance to corrosion, durability, and aesthetic appeal. Stainless steel sheets are employed in the production of architectural components, kitchen appliances, storage tanks, machinery parts, and decorative items, among others.

- Q:How do stainless steel sheets compare to other materials, such as aluminum or carbon steel?

- Stainless steel sheets offer distinct advantages when compared to other materials like aluminum or carbon steel. They have superior corrosion resistance, making them ideal for applications in harsh environments or industries like food processing. Stainless steel sheets also possess high heat resistance, strength, and durability, making them suitable for various structural and industrial purposes. While aluminum is lightweight and has good conductivity, it lacks the same level of strength and corrosion resistance. Carbon steel, on the other hand, is strong but more susceptible to corrosion. Overall, stainless steel sheets provide a balance of strength, durability, and corrosion resistance, making them a preferred choice in many industries.

- Q:Are stainless steel sheets good for high-temperature applications?

- Stainless steel sheets prove to be an exceptional choice for applications at high temperatures. With a high melting point that typically ranges from 1400 to 1450 degrees Celsius (2552 to 2642 degrees Fahrenheit), stainless steel becomes suitable for environments with elevated temperatures. Moreover, this type of steel displays remarkable resistance to oxidation when subjected to high temperatures, effectively preventing the formation of scales or rust that could potentially weaken the material. Additionally, stainless steel boasts good thermal conductivity, facilitating efficient heat transfer. These remarkable attributes establish stainless steel sheets as a dependable option for a diverse range of high-temperature applications, such as industrial furnaces, heat exchangers, boilers, and exhaust systems.

- Q:Are stainless steel sheets suitable for automotive exhaust systems?

- Yes, stainless steel sheets are suitable for automotive exhaust systems. Stainless steel is a preferred material for exhaust systems due to its high resistance to corrosion, heat, and vibration. It can withstand the high temperatures and harsh conditions that exhaust systems are exposed to, making it a durable and long-lasting choice. Additionally, stainless steel has excellent thermal conductivity, which helps in dissipating heat efficiently. It also offers good formability, allowing manufacturers to design and shape the exhaust components as needed. Overall, stainless steel sheets are a reliable and popular choice for automotive exhaust systems.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless steel plate/sheet 304,201,202,310S,316L,316Ti,304L,410,420,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords