Stainless Steel Seamless Steel Pipe Factory

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

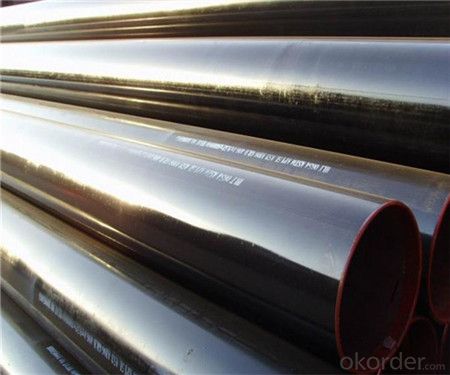

1、Structure of Seamless Pipe ASTM A106/53:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

Application

kitchen and sanitary wares , and Structural use high strength components,furniture

handles , handrails , electroplating and electrolyzing pendants , foods, electron ,

petroleum , construction and decoration , etc

Packing and shipment

Packaged in bundles,as per customers' requirements, it can also bepackagesd as beveled ends, typed marking, black painting, plastic caps protection,woven bags packing

For 20" container the max length is 5.8m; For 40" container the max length is 12m. other options are available based on customer requests. Please discuss when placing orders.

2、Main Features of the Seamless Pipe ASTM A106/53:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Pipe ASTM A106/53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、Seamless Pipe ASTM A106/53 Images:

- Q: What is the cost of stainless steel bars?

- The cost of stainless steel bars can vary depending on various factors such as the grade of stainless steel, the size and shape of the bars, and the quantity being purchased. Generally, stainless steel bars are priced per pound or per kilogram. The current market price for stainless steel can also impact the cost. It is advisable to check with suppliers or manufacturers for the most up-to-date pricing information as it can fluctuate over time. Additionally, special requirements or customization may also affect the cost of stainless steel bars.

- Q: Are stainless steel bars suitable for mining and ore processing?

- Yes, stainless steel bars are suitable for mining and ore processing. Stainless steel is highly resistant to corrosion and has excellent strength properties, making it ideal for harsh environments and applications involving chemicals and moisture. It can withstand the abrasive nature of mining and ore processing operations, ensuring durability and longevity. Additionally, stainless steel's hygienic properties make it suitable for industries requiring stringent cleanliness standards, such as food processing.

- Q: Are stainless steel bars suitable for outdoor railings?

- Outdoor railings can be effectively made using stainless steel bars. Stainless steel is well-known for its ability to endure and resist corrosion, which makes it an excellent choice for outdoor applications. Even when exposed to rain, snow, or UV rays, stainless steel remains rust-free and intact. Moreover, stainless steel bars provide a sleek and contemporary look that can greatly enhance the overall appearance of outdoor railings. They are also low maintenance, requiring minimal effort to keep them in pristine condition for many years to come. In conclusion, stainless steel bars offer the perfect combination of strength, durability, and aesthetics, guaranteeing reliable and long-lasting outdoor railings.

- Q: Are stainless steel bars suitable for the production of turbine casings?

- Yes, stainless steel bars are suitable for the production of turbine casings. Stainless steel is known for its high strength, corrosion resistance, and temperature resistance, making it an excellent choice for components exposed to extreme conditions in turbines. It provides durability and stability, ensuring the casing can withstand the demanding operational requirements of turbine systems.

- Q: What are the different manufacturing processes for stainless steel bars?

- Stainless steel bars can be produced through various manufacturing processes, each possessing its own unique qualities and benefits. Below are some commonly used methods: 1. The most widely utilized technique for manufacturing stainless steel bars is hot rolling. This process involves passing a heated stainless steel billet through a series of rolling mills to reduce its thickness and shape it into the desired bar size. Hot rolling enhances the strength and durability of the stainless steel bar. 2. Cold drawing is another process where a hot-rolled stainless steel bar is pulled through a die under controlled conditions. This improves the bar's surface finish, dimensional accuracy, and mechanical properties. Cold drawn stainless steel bars are often preferred for applications that require a high level of precision. 3. Peeling is a process that involves removing the outer surface layer of a hot-rolled stainless steel bar using a peeling machine. This results in a smooth and glossy surface finish while also enhancing the bar's dimensional accuracy and straightness. Peeling is commonly employed for stainless steel bars used in industries such as automotive and aerospace, where a high surface quality is necessary. 4. Grinding is a manufacturing process that employs an abrasive wheel to remove material from the surface of a stainless steel bar. This process is typically used to achieve tight dimensional tolerances and improve the surface finish of the bar. Grinding is often utilized for stainless steel bars that require precise dimensions and a high-quality surface. 5. Machining involves the removal of material from a stainless steel bar using cutting tools like drills, lathes, or milling machines. This process is employed to create intricate designs, holes, or threads on the bar's surface. Machining is commonly applied to stainless steel bars that require customized or complex shapes. It is important to note that the choice of manufacturing process depends on factors such as the desired surface finish, dimensional tolerances, mechanical properties, and intended application of the stainless steel bar. Manufacturers carefully select the appropriate process to ensure the bar meets the required specifications and quality standards.

- Q: What is the yield strength of stainless steel bars?

- The yield strength of stainless steel bars varies depending on the grade and type of stainless steel used. In general, stainless steel bars have a higher yield strength than other types of steel due to their unique alloy composition. The yield strength for stainless steel bars typically falls within the range of 30,000 to 100,000 pounds per square inch (psi). However, it is important to note that this value can change depending on factors such as the specific grade, heat treatment, and manufacturing process. Therefore, it is advisable to consult the manufacturer or refer to the specifications provided by the supplier to obtain the exact yield strength for a particular grade or type of stainless steel bar.

- Q: Can stainless steel bars be engraved?

- Yes, stainless steel bars can be engraved. Engraving on stainless steel bars is a common practice used for various purposes such as personalization, identification, branding, or decorative purposes. Engraving on stainless steel bars can be done using different techniques such as laser engraving, rotary engraving, or chemical etching. These methods allow for precise and detailed engravings, ensuring a long-lasting and durable result. However, it is important to note that the hardness and composition of stainless steel can make the engraving process more challenging compared to softer materials. Therefore, it is advisable to consult with professionals or experienced engravers to ensure the best results when engraving stainless steel bars.

- Q: Can stainless steel bars be heat treated?

- Yes, stainless steel bars can be heat treated. Heat treating stainless steel bars involves heating the material to a specific temperature, holding it at that temperature for a certain period of time, and then cooling it down in a controlled manner. This process changes the internal structure of the stainless steel, improving its mechanical properties such as hardness, strength, and ductility. Heat treating stainless steel bars can also help to remove internal stresses, improve corrosion resistance, and enhance the overall performance of the material. However, it is important to note that not all grades of stainless steel can be heat treated, as some are designed to be non-heat treatable. Therefore, it is essential to identify the specific grade of stainless steel and consult with a metallurgical expert or refer to the manufacturer's guidelines before attempting to heat treat stainless steel bars.

- Q: Can stainless steel bars be used in chemical storage applications?

- Yes, stainless steel bars can be used in chemical storage applications. Stainless steel is known for its excellent corrosion resistance and durability, making it a popular choice for storing various chemicals. It is resistant to a wide range of chemicals, including acids, alkalis, and solvents, which makes it suitable for storing corrosive substances. Stainless steel bars are also easy to clean and maintain, which is essential in chemical storage applications to prevent contamination. Additionally, stainless steel has high strength and temperature resistance, ensuring the structural integrity of the storage system. Overall, stainless steel bars are a reliable and safe option for chemical storage applications.

- Q: What are the characteristics of martensitic stainless steel bars?

- Martensitic stainless steel bars are known for their high strength, hardness, and wear resistance. They have a martensitic crystal structure, which is achieved through quenching and tempering processes. These bars exhibit excellent corrosion resistance, particularly in environments with low to moderate levels of corrosive agents. Additionally, martensitic stainless steel bars can be easily machined and welded, making them suitable for various industrial applications, including automotive, aerospace, and tooling industries.

Send your message to us

Stainless Steel Seamless Steel Pipe Factory

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords