hot rolled steel strip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Spring Steel:

Spring steel is divided into two types, one is alloy spring steel, and other one is carbon spring steel.

Alloy spring steel is a type that is used for manufacturing springs and other elastic parts. Spring steel should have high ratio of yield strength and tensile strength and elastic limit to make sure that the springs obtain enough power of elastic deformation and can bear much load.

Types of alloy spring steel: Si-Mn spring steel, Si-Cr spring steel, Cr-Mn Spring steel, Cr-V spring steel and so on.

Specification of Spring Strip Steel:

-Material: 30W4Cr2VA

-Standard: GB/T 1222-2007

-Type: Spring Steel

Chemical Composition:

C | Si | Mn | S |

0.26~0.34 | 0.17~0.37 | ≤0.40 | ≤0.030 |

P | Cr | Ni | Cu |

≤0.030 | 2.00~2.50 | ≤0.35 | ≤0.25 |

V | W | | |

0.50~0.80 | 4.00~4.50 | | |

Mechanical Properties:

-Yield Strength σs (MPa): ≥1470 (150)

-Elongation δ10(%):≥7

-Hardness:

1, Hot rolled + Heat treatment, ≤321HB

2, Cold drawn + Heat treatment: ≤321HB

-Impact Power: ≥40

Norm of heat treatment:

1, Quenching: 1050℃~1100℃.

2, Cooled by oil.

3, Tempering: 600℃±50℃.

Usage/Applications of Spring Strip Steel:

-Due to the elements W, Cr and V, this type of spring steel obtain pretty high hardenability and nice mechanical properties under room temperature and high temperature. The tempering stability and hot workability are good.

-Being used under the state of quenching and high temperature tempering. It’s usually used as heat-resisting springs with working temperature below 500℃, like main secure valve spring of furnace and turbine steam seal leaf springs.

Packaging & Delivery of Spring Strip Steel:

-Packing Detail: The products will be well packed.

-Marks: there are two types of marks.

1, Tag marks. To show customers the specifications of products, company name and logo and other information required by customers.

2, Color marks. It’s easy for customers to distinguish them from other products at destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

1, The products can be delivered by bulk vessel or by container.

2, The maximum quantity of loading of container is 25 tons.

3, The products usually are transported to the nearest port from the production place.

Payment:

-Theoretical weight/Actual weight.

-FOB, CFR or CIF.

-Terms of payment: T.T. or L/C at sight.

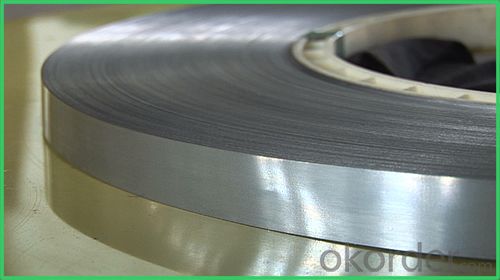

Photos of Spring Strip Steel:

- Q: What are the different surface coatings available for steel strips to improve chemical resistance?

- Some of the different surface coatings available for steel strips to improve chemical resistance include epoxy coatings, polyurethane coatings, fluoropolymer coatings, and ceramic coatings.

- Q: How are steel strips processed for surface coating removal?

- Steel strips can be processed for surface coating removal through various methods. One common method is mechanical stripping, which involves the use of abrasive materials or equipment to physically remove the coating. This can include sandblasting, where high-pressure air or water is used to propel abrasive particles onto the steel surface, effectively stripping off the coating. Chemical stripping is another method used for surface coating removal. In this process, chemicals or solvents are applied to the steel strips to dissolve or soften the coating, making it easier to remove. The strips are then rinsed or washed to remove any remaining residue. Another popular method is thermal stripping, which involves heating the steel strips to high temperatures. This causes the coating to burn off or decompose, allowing it to be easily removed. This method is particularly effective for organic coatings. In addition to these methods, some companies also use advanced techniques such as laser or plasma coating removal. These methods utilize intense heat or energy to vaporize or ablate the coating from the steel surface. Once the surface coating has been removed, the steel strips may undergo further processing such as cleaning, rinsing, or passivation to prepare them for subsequent treatments or applications.

- Q: What is the typical electrical conductivity of steel strips?

- Compared to other metals, steel strips have a relatively low typical electrical conductivity. This is mainly due to the fact that steel primarily consists of iron, which is not a highly conductive material for electricity. The conductivity of steel strips can differ depending on the specific composition and processing methods employed, but it usually falls within the range of 6.99 × 10^6 to 8.43 × 10^6 siemens per meter (S/m). This level of conductivity renders steel strips appropriate for a variety of applications where electrical conductivity is not of utmost importance.

- Q: How are steel strips packaged for shipping?

- Steel strips are typically packaged for shipping by being tightly wound around a core or spool, secured with strapping or bands to prevent unraveling, and then wrapped in protective materials such as plastic or paper to shield them from moisture and damage during transportation.

- Q: How are steel strips tested for internal defects?

- Steel strips are tested for internal defects using various non-destructive testing (NDT) methods. One common technique is ultrasonic testing, which involves sending high-frequency sound waves through the steel strip and measuring the time it takes for the waves to bounce back. Any inconsistencies or defects within the material will cause the sound waves to reflect differently, allowing technicians to identify internal flaws such as cracks, voids, or inclusions. Another method used is magnetic particle inspection, which relies on the principle of magnetism. A magnetic field is created around the steel strip, and if there are any defects present, they will disrupt the magnetic field, causing magnetic particles to cluster around the defect. This makes the flaw visible and easily detectable. Eddy current testing is another widely used technique. It involves passing an alternating current through a probe that is placed near the steel strip's surface. Any internal defects will cause a change in the electrical conductivity of the material, which in turn alters the eddy currents flowing within it. This change is detected by the probe, allowing for the identification of internal flaws. Other methods such as radiographic testing, which utilizes X-rays or gamma rays to penetrate the steel strip and produce an image of its internal structure, or dye penetrant inspection, which involves applying a colored liquid dye to the steel's surface and observing if it seeps into any cracks or defects, are also employed depending on the specific requirements and characteristics of the steel strips. These non-destructive testing methods are crucial in ensuring the quality and integrity of steel strips, as they allow for the reliable detection of internal defects without damaging the material. By identifying these flaws early on, manufacturers can take appropriate actions to rectify or remove defective strips, thereby preventing potential failures or accidents in the future.

- Q: How are steel strips annealed for improved properties?

- Steel strips are annealed to improve their properties through a process called annealing. Annealing involves heating the steel strips to a specific temperature and then gradually cooling them down. This thermal treatment helps to remove any internal stresses within the steel, making it softer and more ductile. To anneal steel strips, they are typically heated to a temperature slightly above the critical temperature, which is the temperature at which the steel undergoes a phase transformation. This temperature may vary depending on the type of steel being annealed. Once the desired temperature is reached, the steel strips are held at that temperature for a specific duration to allow for the desired changes to occur. This duration may also vary depending on the thickness and composition of the steel. After the soaking period, the steel strips are slowly cooled down in a controlled manner. This slow cooling process, also known as furnace cooling, allows the steel to undergo a transformation called recrystallization. Recrystallization helps to refine the grain structure of the steel, making it more uniform and reducing any internal defects. The annealing process improves the properties of steel strips in several ways. It reduces the hardness and brittleness of the steel, making it easier to form and shape. It also increases the ductility and toughness of the steel, making it less prone to cracking or breaking under stress. Additionally, annealing helps to improve the machinability and weldability of the steel, making it easier to work with during various manufacturing processes. In conclusion, annealing steel strips is a crucial step in improving their properties. By carefully controlling the heating and cooling process, steel strips are made softer, more ductile, and less prone to defects. This enhances their overall performance and makes them more suitable for various industrial applications.

- Q: What are the packaging options available for steel strips?

- The packaging options available for steel strips include coils, bundles, pallets, and custom sizes based on specific requirements.

- Q: How are steel strips processed for flexibility?

- Steel strips undergo various manufacturing techniques and treatments to achieve flexibility. One frequently employed method is cold rolling, which involves passing the strip through room temperature rollers to decrease its thickness and enhance flexibility. This process also strengthens and hardens the steel. Moreover, after cold rolling, annealing is often carried out to further improve the strip's flexibility. This entails heating the strip to a specific temperature and gradually cooling it. By doing so, any internal stresses in the steel are relieved, allowing for easier deformation and increased flexibility. In addition, tempering can be utilized to enhance the flexibility of steel strips. This entails heating the steel to a high temperature and rapidly cooling it. Tempering aids in increasing the ductility and toughness of the steel, making it more flexible and resistant to stress-induced cracking or breaking. In certain cases, steel strips may undergo skin-pass rolling. This process involves passing the strip through rollers that gently apply pressure to the surface, resulting in a smoother and more uniform finish. Skin-pass rolling contributes to the flexibility of the steel strip by reducing surface irregularities and enhancing overall quality. In conclusion, a combination of cold rolling, annealing, tempering, and skin-pass rolling is commonly employed to process steel strips for flexibility. These techniques optimize the mechanical properties of the material, ensuring that it can be easily molded, formed, or shaped for various applications without compromising its structural integrity.

- Q: What are the different sizes and dimensions of steel strips?

- Steel strips are available in a range of sizes and dimensions, which depend on their intended use and application. The thickness of steel strips typically falls between 0.1 mm and 6 mm, with options for variation within this range. The width of steel strips can vary from 10 mm to 1500 mm, again with choices available within this range. Lengths of steel strips may vary based on production requirements, but they are often found in standard coil lengths of up to 30 meters or more. The dimensions and sizes of steel strips are determined by factors such as the industry in which they are used, the specific application or manufacturing process, and customer requirements. It is crucial to consult steel suppliers or manufacturers to ascertain the exact sizes and dimensions available for a specific steel strip.

- Q: How are steel strips used in the production of metal staircases?

- Steel strips are commonly used in the production of metal staircases as they offer several advantages. Firstly, steel strips provide structural support and stability to the staircase framework. They are often used as the main structural components, forming the stringers or supports that hold up the treads and risers. The high strength and rigidity of steel allow for the construction of sturdy and durable staircases that can withstand heavy loads and constant use. Additionally, steel strips are used to create the treads and risers themselves. The strips are often shaped and welded together to form solid and secure steps, ensuring a safe and comfortable walking surface. Steel is a preferred material for this purpose due to its resistance to wear and tear, as well as its ability to withstand various environmental conditions. Moreover, steel strips can be customized to fit the specific design requirements of the staircase. They can be cut, bent, and shaped into different sizes and profiles to create unique and aesthetically pleasing staircases. This versatility allows for the creation of various styles, including straight, spiral, and curved staircases. Lastly, steel strips can be finished with different coatings or treatments to enhance their appearance and protect them from corrosion. This ensures that the metal staircases maintain their visual appeal and functionality over time, even in demanding environments. In summary, steel strips play a crucial role in the production of metal staircases by providing structural support, forming the treads and risers, allowing for customization, and offering protection against corrosion. Their strength, durability, and versatility make them an ideal choice for constructing safe and visually appealing staircases.

Send your message to us

hot rolled steel strip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords