Stainless Steel Coil ASTM Standard 200,300,400 Series

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Stainless Steel Coil Description

The surface brightness and flatness of no2B is better than no2D. then through a special

surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses.

2.Main Features of the Stainless Steel Coil

• Decoration

• Daily Necessities

•,Medical Treatment

• Daily Necessities

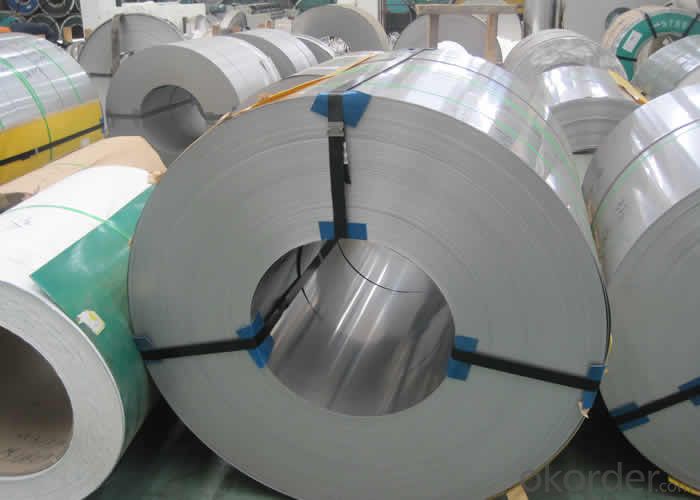

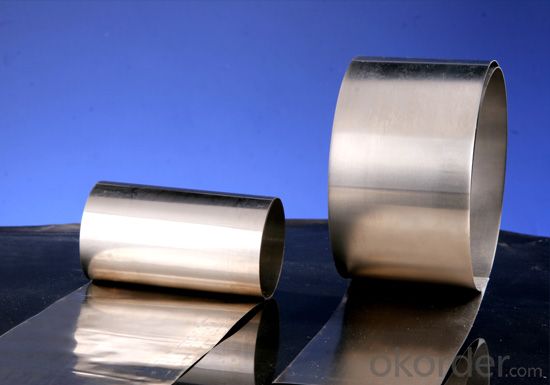

3. Stainless Steel Coil Images

4. Stainless Steel Coil Specification

Product Name | ASTM Standard 200,300,400 Series Stainless Steel Coil |

Standard | JIS AISI ASTM GB DIN |

Grade | 200/300/400 Series |

Thickness | 0.2mm-100mm |

Width | 100mm-2000mm |

Length | According to clients’ requirement |

Surface Finish | 2B ,BA ,8K ,NO4,NO2, NO1 ,Hair line ,EMBOSSED... |

Technique | Cold rolled ,Hot rolled |

Package | Seaworthy packing or as the consumers’ demand |

Application | Be used in manufacture of medical equipment, auto parts, heat-resistant kitchen utensils, electrical accessories , construction decoration ,etc |

Trade Term | FOB CIF |

Payment | T/T , L/C, D/P, D/A, Western Union, MoneyGram |

LoadingPort | Shanghai OR Qingdao |

Delivery Time | 3-7days,mainly in accordance with the quantity |

Report | Material report ,Mechanical performance report |

Certification | ISO9001 |

5.FAQ of Stainless Steel Coil

①Who are you?

We are the manufacturer! We produce stainless steel products

with high quality & very competitive price!Please feel free to

contact us for more information!

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③How about your company?

A world class manufacturer & supplier of castings forging in Stainless Steel Sheet,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

- Q: What are the alloying elements found in steel strips?

- The alloying elements found in steel strips vary depending on the specific grade and intended use of the steel. However, some common alloying elements found in steel strips include carbon, manganese, silicon, phosphorus, sulfur, chromium, nickel, and molybdenum. Carbon is the most important alloying element in steel as it provides strength and hardness. Manganese is often added to increase the hardenability and tensile strength of the steel strips. Silicon is used to enhance the steel's resistance to oxidation and improve its electrical properties. Phosphorus and sulfur are typically present in small quantities but can influence the steel's machinability and brittleness. Chromium is added to enhance the steel's corrosion resistance and increase its strength at high temperatures. Nickel is used to improve the toughness and ductility of the steel, especially in low-temperature applications. Molybdenum is commonly added to increase the steel's strength, hardness, and resistance to corrosion. Other alloying elements like vanadium, titanium, copper, and aluminum can be present, depending on the desired properties of the steel strips. Overall, the alloying elements found in steel strips are carefully selected to achieve specific mechanical, physical, and chemical properties, making the steel suitable for a wide range of applications in various industries.

- Q: What are the recycling options for steel strips?

- Steel strips can be recycled through various methods, including collection and sorting at recycling centers, melting down the strips to create new steel products, or repurposing them for other applications. Additionally, steel strips can be sold to scrap metal yards, where they are processed and eventually reused in the manufacturing of new steel products.

- Q: Are steel strips cost-effective compared to other materials?

- Yes, steel strips can be considered cost-effective compared to other materials for various applications. Steel is a versatile material that offers several advantages such as high strength, durability, and resistance to corrosion. These qualities make steel strips suitable for a wide range of industries, including construction, automotive, manufacturing, and infrastructure. In terms of cost, steel strips can be a cost-effective choice due to their long lifespan and low maintenance requirements. Steel is highly durable and can withstand harsh environments, reducing the need for frequent repairs or replacement. This longevity can result in significant cost savings over time. Additionally, steel is readily available and has a consistent supply, which helps maintain its affordability. The production processes for steel have become more efficient over the years, further contributing to its cost-effectiveness. Furthermore, steel strips can be easily fabricated and customized to meet specific project requirements, reducing wastage and optimizing resource allocation. This flexibility adds to the overall cost-effectiveness of using steel strips. However, it is essential to consider specific project requirements, such as the desired application, budget, and environmental factors, before determining the cost-effectiveness of steel strips compared to other materials. Each material has its own unique characteristics and associated costs, so a thorough analysis should be conducted to ensure the most suitable and cost-effective choice is made.

- Q: How are steel strips used in the production of storage tanks?

- Steel strips are an integral component in the production of storage tanks. These strips are typically used to construct the outer shell or walls of the tank, providing strength and durability to withstand the pressure and weight of the stored materials. The steel strips used for storage tanks are often made from high-quality carbon steel or stainless steel, which have excellent corrosion resistance properties. This is crucial as storage tanks are often exposed to various harsh environments and substances, such as chemicals, acids, or even water. The use of steel strips ensures that the tanks remain stable and secure, protecting the contents and preventing leakage or contamination. In the production process, the steel strips are cut and shaped into the desired dimensions and then welded or sealed together to form the tank's cylindrical or rectangular structure. This welding process is critical to ensure the structural integrity and leak-proof nature of the tank. Moreover, steel strips also play a significant role in reinforcing the tank's walls to withstand the internal pressure exerted by the stored materials. Storage tanks are often used to contain liquids or gases under high pressure, and the steel strips provide the necessary strength to withstand these forces. Additionally, the steel strips can be further reinforced with ribs, flanges, or other structural features to increase their load-bearing capacity. Overall, steel strips are crucial in the production of storage tanks as they provide the necessary strength, durability, corrosion resistance, and structural integrity required for the safe storage of various substances.

- Q: What are the mechanical properties of steel strips?

- The mechanical properties of steel strips include high tensile strength, excellent ductility, good toughness, and high resistance to corrosion and wear.

- Q: Can steel strips be used in the production of kitchen appliances?

- Yes, steel strips can be used in the production of kitchen appliances. Steel is a common material used in the manufacturing of kitchen appliances due to its durability, strength, and resistance to heat and corrosion. Steel strips can be formed into various components and parts such as panels, frames, and shelves, making them suitable for use in kitchen appliances like ovens, refrigerators, and dishwashers.

- Q: How are steel strips rolled?

- To achieve the desired thickness, shape, and surface finish, steel strips undergo a series of hot and cold rolling processes. The process commences with heating a large slab of steel above its recrystallization temperature in a hot rolling mill. It is then passed through rollers to gradually decrease its thickness. The resulting steel strip is then coiled and cooled. Next, the coiled strip goes through a cold rolling mill, which consists of multiple stands of rollers. This mill gradually reduces the thickness of the steel strip to the desired level. Cold rolling not only reduces thickness but also enhances surface finish, mechanical properties, and dimensional accuracy. During the cold rolling process, the steel strip undergoes continuous annealing to eliminate residual stresses and enhance ductility. Annealing involves heating the strip to a specific temperature and then slowly cooling it down. This process refines the microstructure of the steel, leading to improved overall quality. Following cold rolling and annealing, further processes such as skin pass rolling or temper rolling may be applied to the steel strip. Skin pass rolling involves a light reduction in thickness to refine surface finish and remove defects. On the other hand, temper rolling imparts specific mechanical properties and eliminates residual stresses by passing the steel strip through a series of rolls. Finally, the steel strip is typically coated or treated to prevent corrosion or enhance surface properties. This can be achieved through processes like galvanizing, which applies a layer of zinc to protect the steel from rusting. In conclusion, steel strips undergo a combination of hot and cold rolling processes to gradually reduce thickness and improve surface finish and mechanical properties. Additional processing and treatment are carried out to achieve specific characteristics and prevent corrosion.

- Q: How are steel strips processed for slitting into narrower widths?

- To create narrower steel strips, mechanical operations are utilized to process steel strips. The initial step involves uncoiling the steel strip from a large coil and feeding it into a slitter machine. This machine contains multiple circular blades that are spaced apart based on the desired width of the final strips. While the steel strip passes through the slitter machine, the circular blades rotate and cut the strip into narrower widths. The width of each strip is determined by the distance between the circular blades. To ensure the steel strip remains taut throughout the process and avoid any buckling or creasing, the slitter machine is equipped with a tensioning system. Following the slitting process, the steel strip undergoes additional processes to refine and finish the strips. These processes may include edge trimming, where any uneven or rough edges are removed to achieve smooth and precise edges. Additionally, the strips may be leveled to eliminate any residual stresses and maintain flatness. Once all the necessary processing steps are completed, the narrower steel strips are recoiled and packaged for shipment or further processing. The slitting process allows for the production of multiple narrower strips from a single large coil, enhancing the versatility and usability of the steel in various applications. In summary, the processing of steel strips for slitting into narrower widths involves precise cutting, edge trimming, leveling, and recoiling to produce strips that meet specific width requirements and quality standards.

- Q: How are steel strips processed for improved surface finish?

- Steel strips are processed for improved surface finish through various techniques such as pickling, cold rolling, annealing, and skin passing. Pickling involves removing scale and impurities from the steel surface using acid baths. Cold rolling reduces the thickness and improves the surface smoothness through multiple passes between rollers. Annealing is a heat treatment process that eliminates internal stresses and enhances the surface quality. Skin passing further improves the surface finish by applying light pressure and tension to the steel strip. These processes collectively contribute to achieving a desired surface finish for steel strips.

- Q: Can steel strips be used for making automotive suspension components?

- Yes, steel strips can be used for making automotive suspension components. Steel is a commonly used material in the automotive industry due to its high strength, durability, and ability to withstand heavy loads. Steel strips can be shaped and formed into various suspension components such as leaf springs, coil springs, and sway bars. These components play a critical role in supporting the weight of the vehicle, providing stability, and absorbing shocks and vibrations from the road. Steel strips are often preferred for their cost-effectiveness, availability, and ease of manufacturing. Additionally, steel can be engineered and treated to enhance its mechanical properties, making it suitable for demanding automotive applications.

Send your message to us

Stainless Steel Coil ASTM Standard 200,300,400 Series

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords