201, 202,301, 304, 316,304L,316L,309,410,430 Stainless Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

201, 202,301, 304, 316,304L,316L,309,410,430 Stainless Steel Coil

Thickness:0.1-120mm

Width:1000-2000mm

Length: As required

Typical physical properties for stainless steel coil

Grade | Chemical composition | ||||||

C | Si | Mn | P | S | Ni | Cr | |

% | % | % | % | % | % | % | |

309S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.04 | ≤0.030 | 12.00-15.00 | 22.00-24.00 |

Item | 201, 202,301, 304,316,304L,316L,309,410,430 Stainless Steel Coil |

Technical | Hot rolled and cold rolled |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,GB/T3280-2007,EN10095-99,JIS4312,etc |

Material | 201, 202,301, 304,316,304L,316L,309,410,430 |

Surface | NO.1,2B, mirror finish,4K,8K,Hairline finish |

Thickness | 0.1-120mm |

Width | 1000-2000mm |

Price term | FOB,CFR,CIF,CNF |

Application | Stainless steel coil applies to construction field, ships building industry, petroleum, chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Stainless steel coil can be made according to the customer’s requirements. |

Contact | If you have any question, please feel free to contact me. |

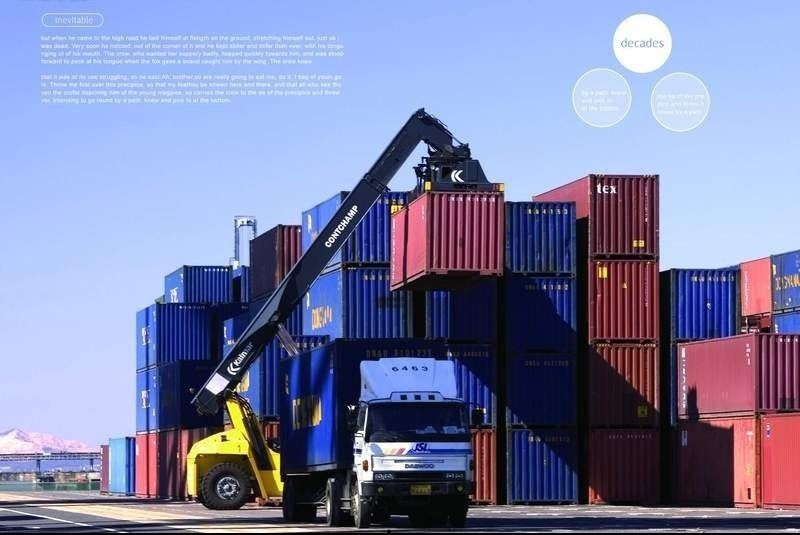

Packaging & shipping

Standard export seaworthy packing (with waterproof paper, metal belt pack sheet,

then put them in wooden pallet, then put in container) or customized.

Products are packed and labeled according to the regulations and customer's request.

Grate car is taken to avoid any damage which might otherwise be caused during storage

or transportation. In addition, clear labels are tagged on the otside of the packages

for easy identification of the product I.D. and quality information.

20 ft - GP: 5.8m (Length) * 2.13m (Width) * 2.18m (Hight) ------ About 23MTS

40 ft - GP: 11.8m (Length) * 2.13m (Width) * 2.18m (Hight) ------ About 27MTS

40 ft - HG: 11.8m (Length) * 2.13m (Width) * 2.72m (Hight) ------ About 27MTS

Production Machines

Application

Applications of Stainless Steel Coil:

1.Automotive: Automotive trim and molding/Difficult-to-form exhaust-system components, tubular manifolds, mufflers/Exhaust manifold and other exhaust-system components, catalytic converter shells, clamps

2. Construction: Gutters and downspouts, roofing, siding

3. Kitchenware: Cooking utensils, dishwashers, ovens, range hoods, refrigerators, skewers 4.Chemical processing: Oil refinery equipment, oil burner and heater parts

5. Appliances: Hot water tanks, residential furnaces

6. Power generation: Heat Exchanger tubing

7. Farming: Dry fertilizer spreaders/Farm animal pens

FAQ

why choose us?

1. All products are made of high-quality imported raw materials.

2. Our product passed SGS,BV,ISO certifications etc.

3. We are nominated as the AAA enterprise .

4. High corrosion resistant

5. Quickest and most efficient Response to Your Enquiry.

6..Stocked products and prompt delivery

7.Multiple payment terms

8.We offer competitive price(high quality)with best service

9.We have high technical production line

10.We have win high reputation based on best quality products

- Q:Can stainless steel strips be used in the production of jewelry clasps?

- Indeed, the utilization of stainless steel strips is viable for crafting jewelry clasps. This material boasts durability and resistance to corrosion, rendering it suitable for diverse applications, including the realm of jewelry production. By shaping and molding stainless steel strips, an array of designs for clasps can be achieved, thereby offering both practicality and visual appeal. Furthermore, the enduring resistance of stainless steel to tarnishing and fading guarantees the longevity of the clasps' aesthetic appeal. Given its versatility, jewelry designers and manufacturers frequently favor stainless steel as a prime option.

- Q:Are stainless steel strips suitable for springs?

- Yes, stainless steel strips are suitable for springs. Stainless steel is known for its high strength, corrosion resistance, and durability, making it an excellent choice for spring applications. It can withstand heavy loads, maintain its shape, and resist rust and corrosion, making it ideal for various spring applications in industries such as automotive, aerospace, and manufacturing.

- Q:What is the maximum width available for stainless steel strips?

- The maximum width of stainless steel strips can differ based on the manufacturer and supplier. Generally, these strips are typically found in widths that range from 0.5 inches to 24 inches. Moreover, certain manufacturers may provide wider strips, reaching up to 48 inches or even more, depending on their production facilities' capabilities and the specific requirements. To ascertain the precise maximum width capabilities for stainless steel strips, it is crucial to consult with individual suppliers.

- Q:How are stainless steel strips different from galvanized steel strips?

- The composition, appearance, corrosion resistance, and uses of stainless steel strips and galvanized steel strips are different. To start with, their composition differs significantly. Stainless steel strips primarily consist of iron and have a higher percentage of chromium, which provides excellent corrosion resistance. In contrast, galvanized steel strips are produced by coating regular steel with a layer of zinc, which acts as a protective barrier against corrosion. Moreover, their appearance sets them apart. Stainless steel strips have a shiny, silver-like look due to their high chromium content. Conversely, galvanized steel strips have a duller, matte finish owing to the zinc coating. Regarding corrosion resistance, stainless steel strips excel in this aspect. They can withstand corrosion and rust, even in harsh environments or when exposed to moisture. While galvanized steel strips also offer decent corrosion resistance, they may eventually corrode or develop rust if the zinc coating becomes damaged or wears off. Lastly, their uses can vary greatly. Stainless steel strips find extensive application in areas where corrosion resistance and durability are crucial, such as the construction of kitchen appliances, medical equipment, automotive parts, and decorative purposes. On the flip side, galvanized steel strips are commonly employed in outdoor applications or environments where corrosion resistance is necessary but not critical, such as roofing, fencing, and electrical conduits. To summarize, stainless steel strips and galvanized steel strips differ in terms of composition, appearance, corrosion resistance, and applications. Stainless steel provides superior corrosion resistance and is ideal for applications that require durability. In contrast, galvanized steel is frequently utilized in outdoor settings where corrosion resistance is necessary but not of utmost importance.

- Q:Can stainless steel strips be used in electrical enclosures?

- Indeed, electrical enclosures can incorporate stainless steel strips. The preference for stainless steel in electrical enclosures stems from its resilience against corrosion, commendable durability, and capacity to endure challenging surroundings. Stainless steel strips can serve as reinforcements for the enclosure's structure or contribute to grounding. Moreover, stainless steel boasts commendable electrical conductivity, rendering it suitable for electrical applications. Accordingly, it is crucial to select the precise grade of stainless steel that aligns with the enclosure's distinct requirements, guaranteeing peak performance and longevity.

- Q:What are the common uses of stainless steel strips in the food manufacturing process?

- Due to their unique properties and hygienic nature, stainless steel strips find wide application in the food manufacturing process. Some typical uses of stainless steel strips in this industry include: 1. Conveyor Belts: Food processing plants commonly employ stainless steel strips as conveyor belts. These strips possess corrosion resistance and can withstand high temperatures, making them suitable for transporting food items throughout various production stages. 2. Food Processing Equipment: Stainless steel strips are utilized in the construction of equipment such as mixers, blenders, grinders, and slicers. The strength and durability of these strips ensure that the equipment can withstand the demanding requirements of food processing while maintaining a clean and hygienic surface. 3. Food Storage and Handling: Stainless steel strips are used to fabricate storage containers, shelves, and racks in food manufacturing facilities. The non-reactive nature of stainless steel guarantees that it won't contaminate food products, thereby preserving their quality and safety. 4. Food Packaging: Stainless steel strips are employed in the production of food packaging materials, including cans, trays, and lids. These strips provide robust and durable packaging, safeguarding the food from external contaminants and ensuring its freshness and longevity. 5. Heat Exchangers: The construction of heat exchangers, which play a crucial role in the food manufacturing process, often involves stainless steel strips. Heat exchangers facilitate the heating or cooling of food products, maintaining the desired temperature for processing, pasteurization, or storage. 6. Sanitary Fittings: Stainless steel strips are used to fabricate sanitary fittings such as pipes, valves, and connectors. These fittings are vital in maintaining a hygienic environment in food processing facilities, as stainless steel is easy to clean, resistant to bacterial growth, and does not contaminate food products. Overall, the widespread usage of stainless steel strips in the food manufacturing process revolves around their corrosion resistance, durability, cleanliness, and ability to preserve food quality and safety.

- Q:Can stainless steel strips be used for jewelry findings?

- Yes, stainless steel strips can be used for jewelry findings. Stainless steel is a durable and corrosion-resistant material, making it suitable for various jewelry components such as clasps, jump rings, and connectors. Its strength and versatility make it a popular choice among jewelry designers.

- Q:How do stainless steel strips perform in the presence of alkalis?

- In the presence of alkalis, stainless steel strips generally exhibit good performance. The primary reason for the corrosion resistance of stainless steel is the presence of chromium, which creates a passive oxide layer on the steel's surface. This oxide layer effectively prevents the steel from reacting with its surroundings, including alkalis. Alkalis, such as caustic soda or potassium hydroxide, are typically strong bases with a high pH. Stainless steel is renowned for its corrosion resistance in alkaline environments, thanks to the strong barrier provided by the passive oxide layer against the attack of alkalis. However, it is important to note that the performance of stainless steel in alkalis can vary depending on the specific grade of stainless steel used, as well as the concentration and temperature of the alkali solution. In certain cases, highly concentrated solutions or elevated temperatures can result in localized corrosion or stress corrosion cracking in stainless steel. To ensure optimal performance, it is advisable to carefully select the appropriate grade of stainless steel based on the specific alkali being used, taking into account factors such as concentration, temperature, and exposure time. Seeking advice from corrosion experts or stainless steel manufacturers can offer further guidance on choosing the best stainless steel grade for a particular alkali application.

- Q:What is the creep resistance of stainless steel strips?

- The ability of stainless steel strips to withstand deformation or elongation under sustained high temperatures and constant stress is referred to as their creep resistance. Compared to other materials, stainless steel is well-known for its excellent creep resistance. This is primarily attributed to its high chromium content, which leads to the formation of a protective oxide layer on the steel's surface, thereby enhancing its resistance to oxidation and creep deformation. Furthermore, stainless steel strips often contain additional alloying elements like nickel, molybdenum, or titanium, which further contribute to their creep resistance. These alloying elements serve to strengthen the steel and improve its capacity to resist deformation at elevated temperatures. Consequently, stainless steel strips are a dependable choice for applications where creep resistance is crucial, such as in high-temperature environments or under constant stress.

- Q:What are the maximum operating temperatures for stainless steel strips?

- The maximum operating temperatures for stainless steel strips vary depending on the specific grade of stainless steel being used. However, in general, most stainless steel strips have a maximum operating temperature range of 1500°F to 1600°F (815°C to 870°C). It is important to note that these temperature limits can vary depending on factors such as the specific alloy composition, surface finish, and the intended application of the stainless steel strips. Therefore, it is always recommended to consult the manufacturer's specifications or seek professional advice to determine the exact maximum operating temperature for a specific grade of stainless steel strips.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

201, 202,301, 304, 316,304L,316L,309,410,430 Stainless Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords