Stainless Steel Coil Cold Rolled 304 With High Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Coil Cold Rolled 304 With Good Quality

1.Structure of Stainless Steel Coil Cold Rolled 304 With Good Quality

Cold Rolled stainless steel Coil with good quality is one of the raw material of the cold rolled stainless steel Coil, which can be used

directly in many places. Stainless Steel (Stainless Steel) is short for acidproof Stainless Steel, resistant to weak corrosive medium

such as air, steam, water, or with a Stainless Steel grade.

2.Main Features of Prefabricated Steel Structure High Building Project

The purpose of the different requirement for welding performance are different.1 Kind of tableware generally do not require the performance

of welding, even including some pot class enterprise. But the vast majority of products all need raw materials welding performance is good,

like the 2 kinds of tableware, thermos flask, steel pipes, water heaters, water dispensers, etc.

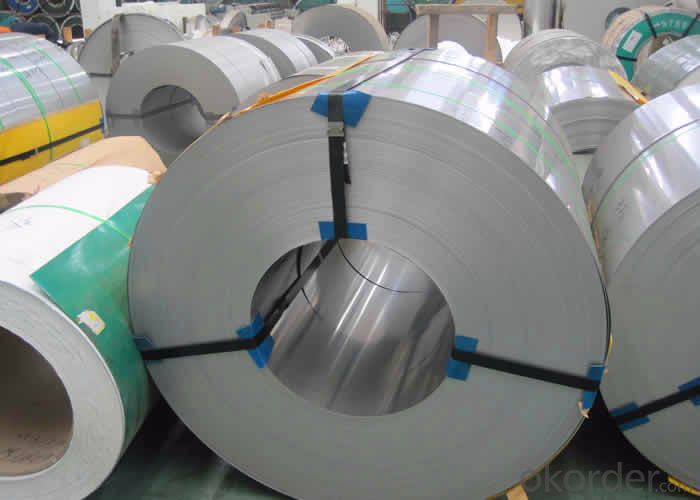

3. Stainless Steel Coil Cold Rolled 304 With Good Quality Images

4. Stainless Steel Coil Cold Rolled 304 With Good Quality Specification

Austenitic stainless steel The title Chromium is more than 18%, still contain about 8% of the nickel and small amounts of molybdenum,

titanium, nitrogen and other elements. Good comprehensive performance, corrosion resistant to a variety of media. Number of austenitic

stainless steel is commonly used one cr18ni9, 0 cr19ni9, etc. In the Wc < 0.08% 0 cr19ni9 steel, steel grade is marked as "0". This class

contains large amounts of Ni and Cr in steel, make steel in austenitic state at room temperature. This kind of steel has good plasticity

and toughness, weldability and corrosion resistance and nonmagnetic or weak magnetic, the corrosion resistance in oxidizing and reducing

medium are good, used to make acid equipment, such as corrosion resistant containers and equipment lining, pipelines, nitric acid

resistant equipment parts, etc., also can be used as the main body of watches and clocks jewelry stainless steel material. Austenitic

stainless steel with solid solution treatment, the steel heating to 1050 ~ 1150 ℃, then water-cooled or air-cooled, for single-

phase austenitic organization.

5. Applications of Stainless Steel Coil 304 With Good Quality

1. Kitchenware: tableware, cookware, Stoves…

2. Food packing: storage cans, food containers…

3. Construction: bridge, roofing, wall, decoration, bathroom accessories…

4. Precision instruments: electrical products, aerospace…

5. Others: automotive parts, machine building, chemical processing, farming…

6.FAQ of Stainless Steel Coil 304 With Good Quality

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory.

Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM

casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict

quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

③How is the packaging and delivery?

Standard export packing (Coil: waterproof paper + protective steel ring; Circle: wooden box), or as your requirement and the delivery term

is based on the project.

④How long can we receive the product after purchase?

In the purchase of product within 20 working days, We will arrange the factory delivery as soon as possible. The specific time of receiving

is related to the state and position of customers. Commonly 20 to 40 working days can be served.

- Q: Can stainless steel strips be used in heat exchangers?

- Heat exchangers can indeed utilize stainless steel strips. Stainless steel is a favored option for heat exchangers because of its remarkable resistance to corrosion, ability to withstand high temperatures, and durability. It can endure the challenging operating conditions and thermal fluctuations frequently encountered in heat exchanger applications. Furthermore, the sleek surface of stainless steel strips aids in reducing fouling and promoting efficient heat transfer. Moreover, stainless steel boasts commendable mechanical properties, rendering it appropriate for different types of heat exchangers, including shell and tube, plate, and finned heat exchangers.

- Q: Are 111 stainless steel strips resistant to scaling at elevated temperatures?

- 111 stainless steel strips exhibit resistance to scaling at elevated temperatures. Due to its composition and properties, 111 stainless steel is highly resistant to oxidation and scaling when exposed to high temperatures. This stainless steel variant contains a greater proportion of chromium, which generates a protective oxide layer on the strip's surface. This oxide layer functions as a shield, inhibiting the steel from reacting with oxygen and other atmospheric elements. Consequently, the integrity of the 111 stainless steel strips remains intact, enabling them to withstand scaling even under elevated temperature conditions.

- Q: Are stainless steel strips suitable for elevator doors?

- Yes, stainless steel strips are suitable for elevator doors. Stainless steel is a durable and corrosion-resistant material that is widely used in various applications, including elevator doors. Its strength and resistance to wear make it an ideal choice for elevator doors, as they are subject to heavy usage and constant contact with passengers. Additionally, stainless steel has a sleek and modern appearance, which can enhance the overall aesthetic of the elevator and provide a professional and sophisticated look. Overall, stainless steel strips offer the necessary durability, functionality, and visual appeal required for elevator doors.

- Q: Can stainless steel strips be used in the food processing conveyors?

- Food processing conveyors can indeed utilize stainless steel strips. Stainless steel is a favored option for food processing equipment due to its resistance to corrosion, hygienic properties, and ease of cleaning. Conveyor belts commonly incorporate stainless steel strips because they provide robustness and durability while ensuring the preservation of food safety and preventing contamination. The seamless surface of stainless steel further impedes the accumulation of bacteria, rendering it appropriate for employment in the food industry. Moreover, stainless steel is non-reactive, guaranteeing that it does not affect the taste or interact with the food being transported. Overall, the dependability, hygiene, and corrosion resistance of stainless steel strips make them an outstanding selection for food processing conveyors.

- Q: What are the common finishes available for stainless steel strips?

- The common finishes available for stainless steel strips include brushed, mirror, satin, and matte.

- Q: What are the common uses of stainless steel strips in the automotive suspension systems?

- Stainless steel strips are commonly used in automotive suspension systems for various purposes such as reinforcing and strengthening components, reducing vibrations and noise, improving durability and corrosion resistance, and providing stability and support to the overall suspension system.

- Q: How does the price of stainless steel strips compare to other materials?

- The price of stainless steel strips tends to be higher compared to other materials due to its durability and corrosion resistance. However, it offers excellent long-term value and is often preferred for applications where strength and resistance to wear and tear are crucial.

- Q: How do stainless steel strips handle exposure to acids?

- Stainless steel strips are highly resistant to the corrosive effects of acids. This is due to the presence of chromium in the composition of stainless steel, which forms a protective oxide layer on the surface of the metal. This oxide layer acts as a barrier, preventing the acid from coming into direct contact with the steel and thereby reducing the risk of corrosion. Additionally, stainless steel also contains other alloying elements such as nickel and molybdenum that further enhance its resistance to acids. However, it is important to note that the performance of stainless steel strips can vary depending on the specific type and concentration of acid being exposed to. In some cases, certain aggressive acids may still cause some degree of corrosion, especially at elevated temperatures or prolonged exposure. Therefore, it is advisable to consult with a corrosion specialist or refer to specific guidelines to ensure the appropriate grade of stainless steel is chosen for a particular acid exposure application.

- Q: Can stainless steel strips be used in chemical reactors?

- Certainly, chemical reactors can utilize stainless steel strips. The chemical industry extensively employs stainless steel owing to its remarkable resistance to corrosion. Its ability to withstand diverse chemicals, such as acids, bases, and organic solvents, renders it suitable for application in chemical reactors. Stainless steel strips can be transformed into different forms and sizes to cater to the precise demands of a chemical reactor. Furthermore, stainless steel's exceptional strength and durability make it a perfect choice for enduring the harsh circumstances and pressures typically encountered in chemical procedures.

- Q: What is the tensile strength after annealing of stainless steel strips?

- Various factors, including the specific grade of stainless steel, the parameters of the annealing process, and the intended application of the strips, influence the tensile strength of stainless steel strips after annealing. Annealing is a heat treatment process that involves subjecting the stainless steel strips to a specific temperature and gradually cooling them in order to modify their microstructure and enhance their mechanical properties. For stainless steel, annealing serves to alleviate internal stresses, increase ductility, and improve resistance to corrosion. In general, stainless steel strips tend to exhibit improved tensile strength after annealing compared to their initial state. However, the actual tensile strength achieved after annealing will vary depending on the factors mentioned above, especially the grade of stainless steel. Different grades of stainless steel possess distinct chemical compositions and mechanical properties, which affect their response to annealing. It should be noted that the annealing process must be carefully controlled to prevent excessive softening or grain growth, as these can result in a reduction in tensile strength. The specific annealing parameters, such as temperature, duration, and cooling rate, must be optimized to achieve the desired combination of tensile strength, ductility, and other mechanical properties. Ultimately, determining the tensile strength of stainless steel strips after annealing requires considering the specific grade of stainless steel, the parameters of the annealing process, and conducting suitable mechanical tests. Seeking advice from metallurgical experts or referring to technical specifications provided by stainless steel manufacturers can provide more precise information regarding the expected tensile strength after annealing for a particular grade of stainless steel.

Send your message to us

Stainless Steel Coil Cold Rolled 304 With High Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords