Custom Rubber Seal Strip for Door&Window Fireproof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Custom Rubber Seal Strip for Door&Window Fireproof :

1. Brief Description of Custom Rubber Seal Strip for Door&Window Fireproof

Our solid rubber profiles include rubber u channel, glazing rubber, rubber cord, rubber tube, rubber strip, rubber flocking, trim seal, door and window seals, etc.

The types of rubber we used in making rubber profiles include NBR (Buna-N), EPDM, Neoprene (CR), Silicone and Viton.

EPDM 65+/-5 is the most popular material.

2. Main Features of Custom Rubber Seal Strip for Door&Window Fireproof

1).Ozone and chemical resistance

2).High temperature resistance

3). Excellent weather and water resistance

4).Anti-aging, anti-radiation, good flexibility, good elasticity

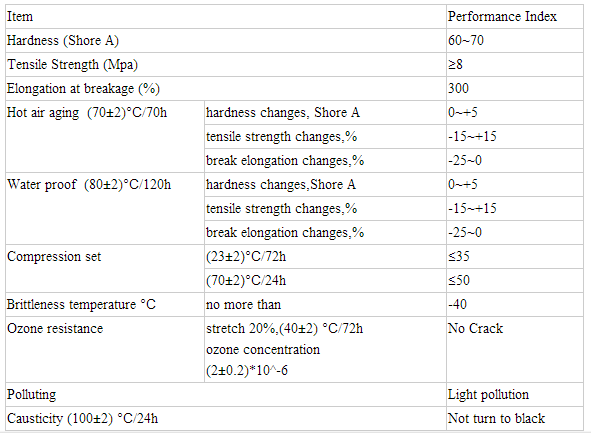

3. Main Specification of Custom Rubber Seal Strip for Door&Window Fireproof

4. Pictures of Custom Rubber Seal Strip for Door&Window Fireproof

5. FAQ

1.Q: Do you produce standard parts?

A: No, We do non-standard parts only, customised parts, OEM. According to customers design, drawing or samples.

2. Q: Your MOQ?

A: We do even prototype. No MOQ, or we can say, MOQ is 1pc.

3. Q: Your Product life time?

A: Usually, rubber seal strips can be used about 10 years.

4. Q: Your Product making time?

A: Usually, within 30 days. According to the quantity,we may refund the R$D spendings

5. Q: Your sample lead time?

A: Usually 10 - 15 days after mould's done.

6. Q: Your paymet terms?

A: We accept T/T, L/C, Paypal, Escrow, Western union, Money gram, D/P, D/A, Cash, and O/A.

- Q: Does antirust oil affect rubber?

- Rust proof oil is a kind of oil which is reddish brown and has anti rust function. It consists of oil soluble corrosion inhibitor, base oil and auxiliary additives. According to the characteristics and application of rust oil sample images can be divided into fingerprint to remove antirust oil, antirust oil, water dilution dilution solvent antirust oil, lubricating oil, seal antirust oil, antirust oil, replacement of thin oil, rust proof grease and rust proof oil. The rust proof oil commonly used inhibitor of fatty acid or naphthenic acid alkaline earth metal salt and naphthenic acid lead, zinc naphthenate, petroleum sulfonate, barium sulfonate, calcium sulfonate, three oleic acid, two tallow amine rosin amine etc..

- Q: What are the common rubber products, please tell me

- Rubber is a high elastic polymer compound, which has high elasticity that other materials do not have, so it is also called elastomer. Its main feature is the enormous molecular weight

- Q: What gum does rubber and metal stick together?

- JL-499 resistance to 150 degrees high temperature instant glue: waterproof, high temperature resistance, with metal, electroplating materials, plastic, rubber and so on between the bonding, metal bonding, high strength, impact resistance, peeling. With high performance, high strength, single component, waterproof, high temperature resistance, anti-aging and other excellent performance, it is suitable for continuous production line operation. It is used for bonding metal, electroplating material, metal, rubber, electronic component, circuit board, glass, ceramic and so on.

- Q: How are rubber wires processed?

- [summary] the main raw material is rubber, rubber products with various agents, as well as the fiber and metal skeleton material, the basic production process of rubber products including plastication, mixing, calendering, extrusion, molding, curing 6 basic processes.The processing process of rubber is mainly to solve the process of plastic and elastic contradictions, through various means of processing, the elastic rubber has become the plastic rubber, adding various in the preparation of semi-finished products, and then through the vulcanization is has semi-finished plastic and rubber products into high elasticity and good mechanical performance the.

- Q: How can the frictional properties of rubber improve?

- Because of its high elasticity and low modulus, the friction and wear properties of rubber are greatly affected by their physical and mechanical properties. The hardness of rubber is smaller, contacting with a rigid object, the real contact area is large, and the real size of the contact area is an important factor, so the friction rubber hardness, have more effect on the friction performance.

- Q: How to maintain and store the rubber material?

- Rubber itself is a shelf-life, you can ask the supplier to warranty, above all, as fillers, such as calcium carbonate, carbon black, long time no problem, also have a shelf life of antioxidant promoter, especially individual species. When storing, pay attention to fire prevention, moisture-proof, away from the high temperature, avoid direct sunlight, of course, the general "first in first out" is a must follow the truth.

- Q: The silica gel of the kettle is the white one that is waterproof and leaked out

- Natural rubber (NR) is mainly composed of rubber hydrocarbons (polyisoprene), containing a small amount of protein, water, resin acids, sugars and inorganic salts. The utility model has the advantages of large elasticity, high extension strength, high tear resistance and electrical insulation, good abrasion resistance and drought resistance, good processability, easy adhesion to other materials, and superior performance in synthetic rubber in comprehensive performance. The disadvantage is that oxygen and ozone resistance is poor, easy aging, metamorphism, oil and solvent resistance is bad, resistance to acid and base corrosion is low; heat resistance is not high. Temperature range: about 60 DEG C 80. Make tires, rubber shoes, hose, tape, wire and cable insulation and sheath, and other general products. The utility model is especially suitable for making torsional vibration eliminator, engine shock absorber, machine support, rubber metal suspension element, diaphragm and molded product.

- Q: What is the difference between natural and synthetic rubber?

- Synthetic rubber is made by synthetic methods, and different kinds of rubber can be synthesized with different raw materials (monomers).

- Q: Why does rubber stink?

- The word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process. In 1770, British chemist J. Priestley discovered that rubber could be used to erase pencil writing. The material used at that time was called rubber, which has been used so far. The molecular chain of rubber can be crosslinked, and the crosslinked rubber can recover quickly when it is deformed by external force, and has good physical and mechanical properties and chemical stability. Rubber is the basic raw material of rubber industry. It is widely used in making tyres, rubber hoses, tapes, cables and other kinds of rubber products.

- Q: How can rubber products be softened?

- Softener most used in rubber processing oil department softener (this kind of softener is actually physical plasticizer). The oil softener is processed products in petroleum refining process, has good softening effect, rich source, low cost features. This kind of softener including aromatic oil, paraffin oil, naphthenic oil, heavy oil, paraffin, Vaseline, asphalt, petroleum resin and so on. Rubber softener (oil) is a refinery in the oil processing products, it is liquid products with different viscosity, the difference is that contain different hydrocarbon components. The rubber softener (oil) according to the composition of the hydrocarbons can be divided into paraffin base oil, naphthenic oil (naphthenic oil) and aromatic oil (aromatic oil).

Send your message to us

Custom Rubber Seal Strip for Door&Window Fireproof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords