Waterproof Rubber Seal Strip with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Waterproof Rubber Seal Strip with High Quality:

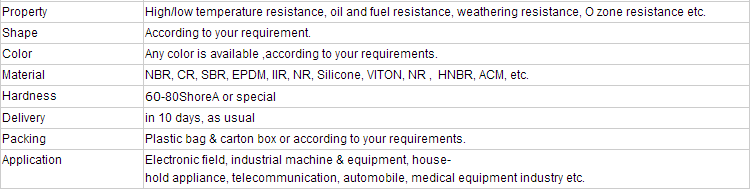

1. Brief Description of Waterproof Rubber Seal Strip with High Quality

We produce rubber seal strip according to customer's requirements, samples, or 2D,3D drawing, any format. If you are interested in our factory please do not hesitate to ask for a similar one or OEM&ODM made.

2. Main Features of Waterproof Rubber Seal Strip with High Quality

1).Environmental safety, good insulation, high temperature, low compression set, strong resilience;

2).smooth surface, uniform density foam;

3).acid, anti-aging, non-toxic;

4).good non-stick surface, good air permeability;

5).using 100 percent high-quality rubber raw materials, and rigorous testing

3. Main Specification of Waterproof Rubber Seal Strip with High Quality

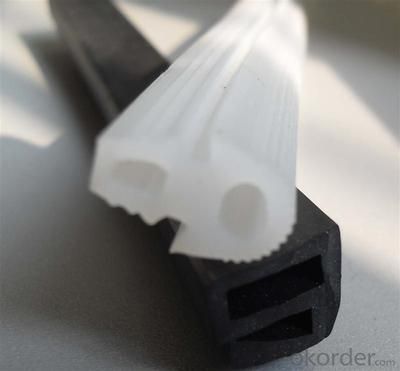

4. Pictures of Waterproof Rubber Seal Strip with High Quality

5. FAQ

1.Q: Do you produce standard parts?

A: No, We do non-standard parts only, customised parts, OEM. According to customers design, drawing or samples.

2. Q: Your MOQ?

A: We do even prototype. No MOQ, or we can say, MOQ is 1pc.

3. Q: Your Product life time?

A: Usually, rubber seal strips can be used about 10 years.

4. Q: Your Product making time?

A: Usually, within 30 days. According to the quantity,we may refund the R$D spendings

5. Q: Your sample lead time?

A: Usually 10 - 15 days after mould's done.

6. Q: Your paymet terms?

A: We accept T/T, L/C, Paypal, Escrow, Western union, Money gram, D/P, D/A, Cash, and O/A.

- Q: Rubber and metal have to be sealed before they are too strong

- The percentage difference between the first compression compression = original section diameter minus the trench size divided by the original O ring diameter O-ring compression is mainly depends on the material hardness and O-ring, O-ring if the hardness is 70 degrees, then the O-ring compression is equal to 20%. Of course, the lower the hardness of the O-ring, O-ring compression is greater, mainly used for low pressure places. Then the O-ring hardness increases the amount of compression of the O-ring is smaller, mainly used for high pressure, pressure resistance, resistance of small environment. And so on, the amount of compression can be any hardness O-ring you need.

- Q: Is vulcanized sole good or rubber sole is good?

- Rubber base, vulcanized bottom are basically the same, rubber vulcanization is only the process of shoe-making, rubber is the bottom of the way vulcanized and uppers together, it is more difficult to open

- Q: How to distinguish between good and bad silicone rubber gasket?

- When the silica gel products are subjected to alternating stress (or strain), the structure and properties of the material change. With the development of fatigue process, the failure of silica gel products is called fatigue damage. Therefore, fatigue is also a way to distinguish the quality of silicone products.

- Q: UV glue can glue rubber products?

- If only the outside screen is glued, the UV glue with a surface fixing type is OK (if the crack is too big and the glue can seep in, it is not recommended to mend), but the crack can still be seen.

- Q: Properties and specific uses of various rubbers

- Rubber is divided into natural rubber and synthetic rubber. Natural rubber is mainly derived from the Hevea tree. When the epidermis of this rubber tree is cut open, it will shed milky juice. It is called latex, and the latex will be natural rubber when it is condensed, washed, molded and dried. Rubber productsSynthetic rubber is made by synthetic methods, and different kinds of rubber can be synthesized with different raw materials (monomers). Such as, butadiene rubber, chloroprene rubber, styrene butadiene rubber and so on. The yield of synthetic rubber has greatly exceeded that of natural rubber, of which the largest yield is styrene butadiene rubber.

- Q: What plastic rubber will not be subjected to oil (such as transformer oil) by quality (e.g., aging, dissolution)?

- The most essential difference between plastics and rubber is plastic deformation when plastic deformation occurs, while rubber is an elastic deformation. In other words, it's not easy to restore the original state after plastic deformation, and rubber is relatively easy. Plastic elasticity is very small, usually less than 100, while rubber can reach 1000 or more. Most of the molding process of plastics is finished

- Q: What are the reasons for rubber cracking after shock absorption of rubber products?

- Shock absorber rubber suspension products, durable rubber cracking:1, rubber aging, weathering, heat resistance;

- Q: What does rubber mean?

- High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers.

- Q: What is the harm of rubber to the human body?

- In use, some contact with the human body rubber requirements are very high, from the choice of gum species (usually silicone rubber and PU), to the use of mixing agents, have strict requirements.

- Q: How to solve the spray of rubber products?

- 1, dry finished products should be packaged sealed, placed in a cool and dry place inventory, avoid sunlightDirect irradiation,2. For the rubber products with the condition of spitting and spitting, the air and temperature at the storage place shall be controlled after the processingDegree and humidity conditions,3, as soon as possible out of storage, not long storage, reduce the aging opportunities of rubber products.

Send your message to us

Waterproof Rubber Seal Strip with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords