High Quality EPDM rubber sealing Strip For Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality EPDM rubber sealing Strip For Sale:

1. Brief Description of High Quality EPDM rubber sealing Strip For Sale

EPDM is kind of half a general rubber. It is on the basement of EPM ,It also provided with the advantages of EPM and superior to the workability of the EPM,It is the most stable material for all the rubber products.

2. Main Features of High Quality EPDM rubber sealing Strip For Sale

>Good aging resistance: The aging resistance of EPDM is as well as the Silicone rubber.

>Good comprehensive physical mechanical resistance: It shows excellent performance especially the Static Sealing and Dynamic Sealing.

>Good corrosion resistance.

>Good flexibility : Meet the GB12002-89 standard perfectly.

>Good elasticity.

>Convenient installation

>Competitive price and prompt delivery.

>According to customers’ design.

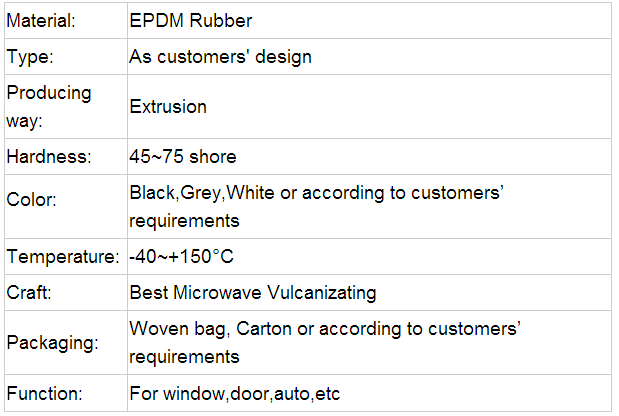

3. Main Specification of High Quality EPDM rubber sealing Strip For Sale

4. Pictures of High Quality EPDM rubber sealing Strip For Sale

5. FAQ

1.Q: Do you produce standard parts?

A: No, We do non-standard parts only, customised parts, OEM. According to customers design, drawing or samples.

2. Q: Your MOQ?

A: We do even prototype. No MOQ, or we can say, MOQ is 1pc.

3. Q: Your Product life time?

A: Usually, rubber seal strips can be used about 10 years.

4. Q: Your Product making time?

A: Usually, within 30 days. According to the quantity,we may refund the R$D spendings

5. Q: Your sample lead time?

A: Usually 10 - 15 days after mould's done.

6. Q: Your paymet terms?

A: We accept T/T, L/C, Paypal, Escrow, Western union, Money gram, D/P, D/A, Cash, and O/A.

- Q: Are there formaldehyde in rubber products, too?

- 1, stimulation: mainly affect performance of formaldehyde for the stimulation of the skin and mucous membrane, formaldehyde is a protoplasmic poison, can bind with protein, when high concentrations of inhaled respiratory severe irritation and edema, eye irritation, headache.2, sensitization: skin direct contact with formaldehyde can cause allergic dermatitis, pigmentation and necrosis, inhalation of high concentrations of formaldehyde can cause bronchial asthma.3. Mutagenicity: high concentration formaldehyde is a genotoxic substance. Laboratory animals can cause nasopharyngeal tumors at high concentrations in the laboratory.

- Q: What's the difference between rubber and silicone?

- Rubber is widely used, mainly the use of elastic rubber, such as rubber tires, rubber rollers, bridge damping, mainly by the industry; silica gel are mostly used in food life appliances, such as pacifiers, spoon for children, a voltage pot seal.

- Q: What are the applications of rubber airbags in the automotive field?

- Rubber accounts for 5% of the total weight of automotive materials, with an average of 100200 rubber parts per car, with a total number of 200500. Along with the automobile reliability, environmental protection and energy saving requirements continue to increase, and rubber materials, product structure optimization, improve the heat resistance, low temperature resistance, long aging, oil resistance, leakage resistance, long-term fatigue, and further reduce the cost has become the main topic of the development of automotive rubber. Fluorine rubber, silicone rubber, acrylic rubber and other special heat-resistant elastic body will still be the mainstream of the future direction of the development of automobile rubber.

- Q: Why does rubber burn black smoke?

- Synthetic rubber inside will be artificially adding carbon black, to reinforce and improve the wear resistance and reduce the cost. For example, many synthetic rubber: butadiene rubber, chloroprene rubber, styrene butadiene rubber must be reinforced in order to achieve the use of carbon black, tensile strength, elongation and wear ideal.

- Q: How do ordinary NBR and EPDM materials differ?

- Nitrile rubber (NBR) is composed of butadiene and acrylonitrile was prepared by emulsion polymerization, nitrile rubber by emulsion polymerization at low temperature, excellent oil resistance, high wear resistance, good heat resistance, strong adhesion. Its disadvantages are low temperature resistance, poor ozone resistance, poor insulation properties, and slightly lower elasticity. Nitrile rubber is mainly used in the manufacture of oil resistant rubber products.

- Q: What is rubber leather?

- Special rubber refers to rubber with some special properties. The main contents are as follows: chloroprene rubber. CR, prepared by polymerization of chloroprene. With good overall performance, oil resistance, combustion resistance, oxidation resistance and ozone resistance. But its density is larger, it is easy to crystallize at room temperature, hard to store, cold resistance is poor. Nitrile rubber. Referred to as NBR, made by copolymerization of butadiene and acrylonitrile. Good oil resistance and aging resistance. It can be used in the air of 120 degrees Celsius or in the oil at 150 degrees centigrade for a long time. In addition, it also has water resistance, air tightness and excellent adhesive properties. Silicone rubber. The backbone consists of alternating atoms of silicon and oxygen, with organic groups on silicon atoms. High and low temperature, ozone resistance, good electrical insulation. Fluorine rubber. A synthetic rubber containing fluorine atoms in the molecular structure. Usually, the number of fluorine atoms in the fluorine containing unit in the copolymer is expressed as fluorine rubber 23, and the copolymer is two vinylidene fluoride and three fluorine vinyl chloride. Fluorine rubber, high temperature, oil resistance, chemical resistance. Polysulfide rubber. Condensation of two halides with sulfides of alkali or alkaline earth metals. Has excellent oil resistance and solvent resistance, but the strength is not high, aging resistance, poor processability, odor, and more with nbr. In addition, there are polyurethane rubber, epichlorohydrin rubber, acrylic rubber and so on.

- Q: How do you remove the rubber on your new slippers?

- There must be some rubber smell, because the bottom containing rubber and plastic bags are used as fine without air so the rubber flavor will be heavier, and you wear for a period of time will not fall, or to buy after put in place of ventilation blowing for one or two days no taste.

- Q: What is the relationship between synthetic rubber and crude oil?

- Synthetic rubber also has disadvantages, the drawing effect of main disadvantage lies in its relatively poor, tearing strength and mechanical properties are relatively poor, but because of synthetic rubber materials than natural rubber has the advantages of low cost, but also a lot of Companies in the production of low-end products preferred.

- Q: What is the difference between PVC rubber and ordinary rubber?

- PVC has strong resistance to oxidizing agents, reducing agents and strong acids. However, it can be corroded by concentrated oxidizing acids such as concentrated sulfuric acid and concentrated nitric acid, and it is also not suitable for contact with aromatic hydrocarbons and chlorinated hydrocarbons.

- Q: There is a crack in rubber products

- It is possible that the sulfur is too fast, the outside is ripe and the inside is slow cooked because of the uneven expansion

Send your message to us

High Quality EPDM rubber sealing Strip For Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords