Light Duty Conveyor Belt PVC Flat Conveyor Belt Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Light Duty Conveyor Belt PVC Flat Conveyor Belt Manufacturer

Product Description:

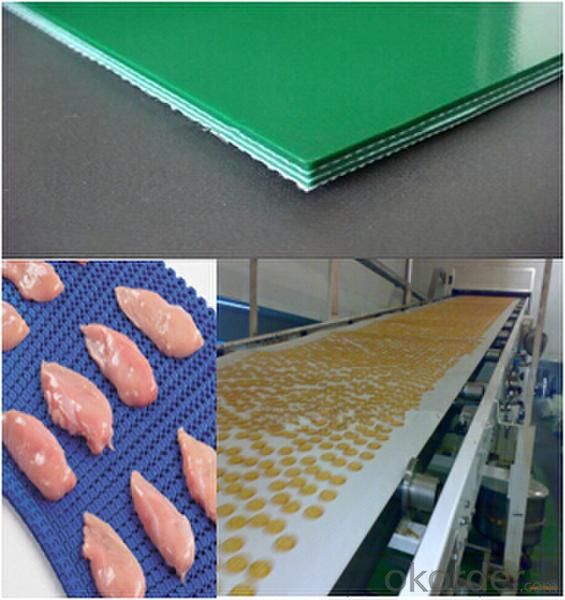

PVC conveyor belt has good elasticity ,not easy to be deformed . It is widely used in good , tobacco , logistics , packaging and other industries . Applicable to coal mine underground transportation ,also can be used in metallurgy ,chemical idustry material handling .

Specifications :

Thikness : 2mm -5mm

Width :300-3000mm

Length :100m / roll

Color : green , dark green , white , black etc

Strength Ver. : 680-3100N/mm

Strength Hor. : 265-450N/mm

Applications & features:

It is widely used in the assembly lines in the areas of food processing, pharmaceutical, electronics, cigarette, printing

Product features: hard wearing, good tensile strength, long service life.

Product specification: One fabric- One rubberized, Two fabric- Two rubberized, Three fabric- three rubberized,ect

Forms of joints: tooth-shaped, stepped&angled, or metal buckle

Pls contact me freely if any inquiry,thank you!

- Q: What are the hazards of rubber accelerators?

- I have been engaged in the rubber industry for many years. I personally think that the accelerator has no harm to people. Wearing gloves, masks and protective measures during operation will not be harmful.

- Q: What's the difference between plastic and rubber?

- 1. the main component of plastic raw material is graphite2.: plastic raw material is made of polymer synthetic resin (polymer) as main ingredients. The infiltration of various auxiliary materials or additives, the pressure at a certain temperature, and has the plasticity and fluidity, can be molded into shape and maintain the same shape of material under certain conditions.

- Q: What does the rubber tire do to people?

- Rubber is an elastic polymer. Rubber can be obtained from the plant sap, can also be man-made, both have many applications and products, such as tires, washers, etc., has become an important economic crop. The cultivation of rubber is mainly concentrated in Southeast Asia, such as Thailand, Malaysia and Indonesia.

- Q: Classification of other rubber sheets of wear-resistant rubber plates

- The wear-resistant rubber sheet used in industry is divided into flat wear-resistant plywood, rhombus wear-resistant plywood and ceramic wear-resistant plywood according to the different types of rubber sheets. At present, a new type of RIT wear-resistant rubber sheet with semi vulcanized layer and chemical reaction with cold vulcanizing glue is more commonly used.As with other wear-resistant plywood, RIT wear-resistant rubber sheet is also divided into RIT flat wear-resistant plywood, RIT Ling wear-resistant plywood and RIT ceramic wear-resistant plywood.

- Q: Does it work in a rubber factory that causes skin irritations?

- Rubber: early rubber is obtained from rubber trees, rubber, grass and other plant latex, processed by the elastic, insulating, impermeable and air material. High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber.

- Q: How is rubber made? What kind of equipment do you need? How much is it?

- Method for making rubber:A latex used in rubber plants, such as rubber trees, rubber, and grasses, for making flexible, insulating, impermeable, and air filled materials. High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q: How do ordinary NBR and EPDM materials differ?

- Nitrile rubber (NBR) is composed of butadiene and acrylonitrile was prepared by emulsion polymerization, nitrile rubber by emulsion polymerization at low temperature, excellent oil resistance, high wear resistance, good heat resistance, strong adhesion. Its disadvantages are low temperature resistance, poor ozone resistance, poor insulation properties, and slightly lower elasticity. Nitrile rubber is mainly used in the manufacture of oil resistant rubber products.

- Q: What is food grade natural rubber?

- Standard rubber, natural rubber latex concentrate only and solid and liquid substances is concentrated latex by high-speed centrifuge after processing, required special barrel plus fresh, dry rubber content is 60%; the standard is a standard solid rubber rubber good solidification, machining, drying, packaging, which according to the impurity content to several levels and it has international standards, countries also have the corresponding standard.

- Q: Does the fuel pipe for automobiles belong to rubber products?

- First of all, make sure that your car is gasoline or diesel, and what parts to follow.

- Q: What are the disadvantages of a rubber roof?

- The rubber roof house is very hot in summer because the rubber is airtight and airtight.

Send your message to us

Light Duty Conveyor Belt PVC Flat Conveyor Belt Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords