Heat-resistant Silicone Rubber Seal Strip

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Heat-resistant Silicone Rubber Seal Strip:

1. Brief Description of Heat-resistant Silicone Rubber Seal Strip

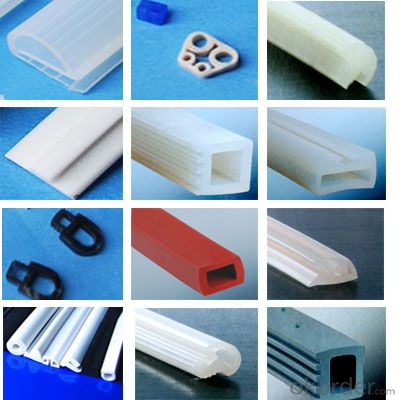

We can customize any kinds of rubber products,such as extruded rubber tube, profiles; molded rubber o ring, gaskets; rubber sheets ,cold shrink cable accessories any other shape of rubber products.

2. Main Features of Heat-resistant Silicone Rubber Seal Strip

1. Ambient temperature from under 50 degree to 300 degree.

2. with backed tape, easy to install

3. High Impact Resistance, good process ability shockproof, soundproof, heatproof, insulation.

4. Different color and shape can be made according to your drawing

5. Transparent, smooth, Soft and flexible. Non-toxic tasteless

6. Function: windows, doors

7. High strength, flame resistant

8. Good elasticity

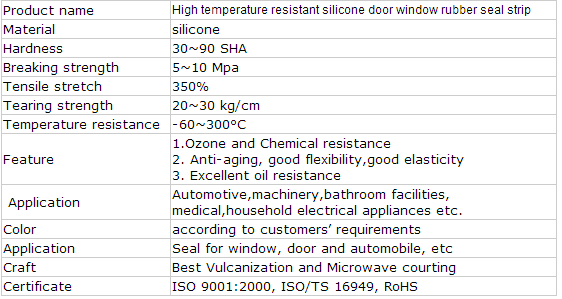

3. Main Specification of Heat-resistant Silicone Rubber Seal Strip

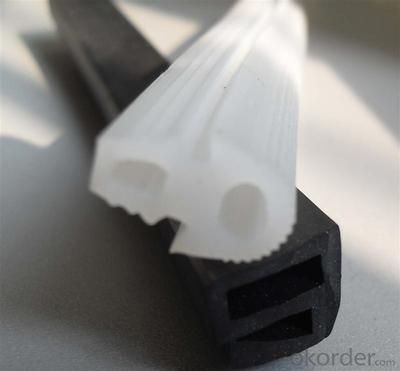

4. Pictures of Heat-resistant Silicone Rubber Seal Strip

5. FAQ

1.Q:Are you a factory or trading company?

A:We are a factory.

2.Q:Can you ensure your quality?

A:Yes,our products have past ISO certificate.We have specialized technical department and

QC team,we will strictly check the material.color,size,performance of the sample step by

step.And every item will be checked before packing.

3.Q:Can you delivery the products on time?

A:Our factory have a production capacity of 400T/month.We will calculate the special delivery

time for you,and ensure the arranged delivery time.

4.Q:Why I choose your products?

A:We can produce the products strictly as your request,and our price is according to the

product material cost,technology cost,labor cost,and other necessary cost.Our price will be

reasonable.

5.Q:Can I get some samples?

A:We offer free sample.

6.Q:Can I visit your factory?

A:Yes, welcome to visit our factory.

- Q: What solvent is used to clear the melted rubber layer?

- Remove the melted rubber layer with chloroform or toluene solvent.Rubber is a latex made from rubber, tree, rubber, and grass. It is made of flexible, insulating, impermeable and air. High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q: Rubber and metal have to be sealed before they are too strong

- The percentage difference between the first compression compression = original section diameter minus the trench size divided by the original O ring diameter O-ring compression is mainly depends on the material hardness and O-ring, O-ring if the hardness is 70 degrees, then the O-ring compression is equal to 20%. Of course, the lower the hardness of the O-ring, O-ring compression is greater, mainly used for low pressure places. Then the O-ring hardness increases the amount of compression of the O-ring is smaller, mainly used for high pressure, pressure resistance, resistance of small environment. And so on, the amount of compression can be any hardness O-ring you need.

- Q: How to enhance the performance of water resistant silicone rubber products

- The purity of the filler and the amount of catalyst residue have great influence on the purity of the filler. In order to improve the steam resistance of silicone products / silicone rubber products, can be used to increase the crosslinking density and the hydrophobic filler method in silica raw material formulation, but should try to avoid the silicone rubber / silicone products using high pressure water vapor over 2MPa under. With this characteristic, the co vulcanizate of siloxane ethylene propylene rubber blends is the best.

- Q: How to test the abrasion resistance of rubber?

- Rubber: the word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process. The finished product is material with elasticity, insulation, waterproof and air.

- Q: How to distinguish between good and bad silicone rubber gasket?

- Silicone products high tear strength anti destruction ability outstanding, long service life, less susceptible to outside interference, the tear strength of silicone products poor general performance gap is easy to appear in the tearing process, so as to force rapid expansion and cracking damage phenomenon.

- Q: Does it work in a rubber factory that causes skin irritations?

- I think it might be the reason for natural rubber. Do you have natural latex in your workshop? Natural latex usually contains a protein with a mass fraction of 0.01-0.02. It can cause allergic reactions to natural rubber latex products (such as latex, gloves, etc.).

- Q: Does anyone know how to deal with the frosting of rubber and how to prevent it?

- The reason: if the formula is in before the precipitation of sulfide precipitation may be white, Zinc Oxide or stearic acid, yellow sulfur may be, after curing products, may be white wax, light green or other color may be. The weather is hot, after curing the product easy to spray cream, can properly reduce the antioxidant.

- Q: What are the bridge rubber air bags used for?

- Note: when the inner mold of the airbag is used, it is necessary to brush the isolating agent to reduce the pumping resistance. The airbag does not allow the oil to replace the isolating agent. On the one hand, the oil will erode the rubber, and the other oil will contaminate the reinforcement. It is ideal to dilute with soap water as a release agent. Soap and water ratio is about 1:20.

- Q: Does the fuel pipe for automobiles belong to rubber products?

- If it is a diesel car, then the high pressure part of the metal pipe only, in the low pressure part of the rubber tube.

- Q: What is the relationship between synthetic rubber and crude oil?

- Synthetic rubber material also has excellent heat resistance, cold resistance, corrosion resistance, and little affected by environmental factors, synthetic rubber materials and suitable for 60 to 250 degrees below zero normal use.

Send your message to us

Heat-resistant Silicone Rubber Seal Strip

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords