Treadmill Golf Pattern PVC Conveyor Belt Treadmill Walking Belt for Gym

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Treadmill Golf Pattern PVC Conveyor Belt Treadmill Walking Belt for Gym

Description of Treadmill Conveyor Belt

PVC light industry conveyor belt

Suitable for light industrial, packing light industrial, transport for tobacco, tea, pieces vegetable, fruit and so on. Also can be used in airport, post office, storage and etc.

PU light industry conveyor belt

Widely used in food industry. Transport the material in bulk, canning and packed In box. The material includes grain, cooky, candy, vegetables, fruit, fowl, meat and so on.

Also widely used in soft material industry. Used in those field, including tobacco, electron, textile, printing and dyeing, machine manufacturing, print and package, paper processing, pottery, marble, wood processing,car shell molding, cable fishing wire, aluminium parts processing and etc.

Features of treadmill belt

thickness:1.4 1.6 1.8 2.0 2.3 2.5 3.1 4.3 4.5 mm

household treadmill: 1.8 2.0 2.3mm

gym treadmill:2.5 3.1 4.3 4.5mm

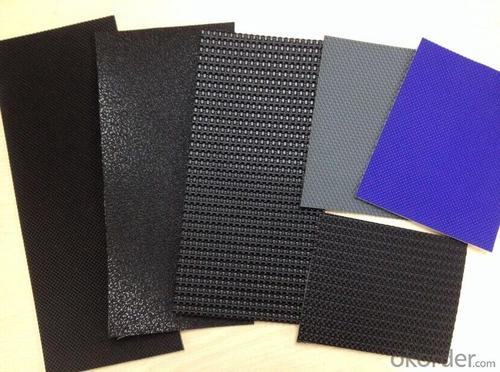

surface: diamond

color: black blue red grey

Know your treadmill belt

A damaged or worn out belt can be dangerous for you and can quickly wear out electrical components of the treadmill.It is better to replace the belt than to risk an injury or more costly repair.

If your belt is running slow, or feels loose, you may assume that the belt needs to be replaced. Often, though, these are indicators of too tight or too loose tension rollers, and can be fixed by either tightening or loosening the tension rollers.

Surface Patterns:

Flat, Grass , Golf, Diamond, Matte surface finish, Small round particles and etc.

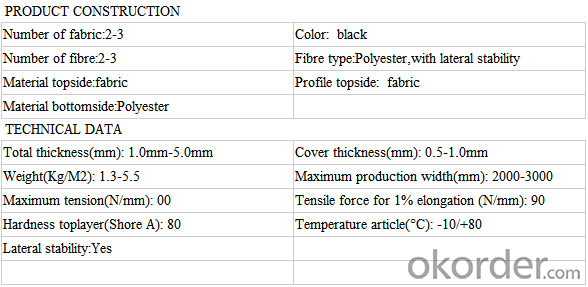

Specification of Treadmill Conveyor Belt

Photos of PVC Treadmill Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the

samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS,

DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you

can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What is the tensile strength of silicone rubber?

- The tensile strength range of silicone rubber is 3.4-14.7Mpa, depending on the formula!

- Q: NR natural rubber manufacturers, who knows Guangdong here, there are manufacturers, a few hair connection is OK

- Chloroprene rubber (CR) by chloroprene do monomer emulsion polymerization of polymers. This rubber molecule containing chlorine atom, so compared with other general rubber: it has excellent oxidation resistance, ozone resistance, non flammable, after the fire can be self extinguishing, the advantages of oil resistance, solvent resistance, acid and alkali resistance, aging resistance, good air tightness; the mechanical performance is better than natural rubber, so can be used for general rubber, also can be used for special rubber. The main disadvantages are poor cold resistance, large proportion, relatively high cost, bad electrical insulation, easy to stick rolling, easy burning and easy sticking. In addition, rubber poor stability, not easy to save. Temperature range: about 45 DEG C ~100. The main requirements for the manufacture of ozone resistance and aging resistance of high cable sheath and various protective cover, protective cover; oil resistance, chemical corrosion resistance of hose, tape and chemical resistant lining; the underground mining with burning rubber, and a variety of molded products, sealing ring, gasket, binder etc..

- Q: How to remove the rubber front?

- At present, there are two kinds of machine trimming on the market: roller grinding and cold trimming at normal temperature. If the product added value is not high, not strong to Feng processing precision, recommended by the economic roller milling Xiu Feng, this is the products into the drum, small friction rub off Feng ball and rely on some products produced by each other. The advantage of this approach is that it is relatively economical.

- Q: How to remove the peculiar smell of rubber products?

- Boiled smell removing method has a long history, has already appeared at the end of 80s, now there is also a part of the factory workshops in using this method (the rubber products produced by cooking in boiling water) this method can eliminate the small part of the reclaimed rubber smell, but most can not eliminate and cannot be eradicated, after a period of time reclaimed rubber continued precipitation and volatile flavor. Boiling water with the exception of flavor, artificial high cost, cumbersome process, the effect can not be sustained, and go to the general effect of flavor.

- Q: What is the relationship between the hardness and tensile strength of rubber pad?

- The main factors affecting the tensile strength of rubber are: the main valence bond, intermolecular force and polymer chain flexibility of macromolecular chains. The relationship between tensile strength and structure of rubber: the intermolecular forces are large, such as polarity and rigid groups;

- Q: For the application of common synthetic rubber, not too long or too difficult, want to do

- Styrene butadiene rubber (SBR) copolymer of butadiene and styrene. The performance is close to natural rubber, is currently the largest production general synthetic rubber, which is characterized by abrasion resistance, aging resistance and heat resistance than natural rubber, natural rubber texture is uniform. The shortcoming is: low elasticity, flex, poor anti tearing properties; processing poor performance, especially since the viscosity difference, green strength is low. The temperature range of about 50 DEG C: ~100. Mainly used to replace natural rubber tire, rubber hose, rubber plate, making shoes and other generic products.

- Q: Can the rubber surface be painted with paint?

- As long as waterproof, dustproof, isolated air is conducive to prolonging the service life of rubber. It can be applied with Vaseline, methyl silicone oil and so on.

- Q: Why do rubber products become so long that they seem to melt and become sticky on the surface?

- Rubber is a word now often refers to natural rubber, it can be said that not all products are easy to sticky rubber. Natural rubber tends to stick because it contains many carbon carbon double bonds and is prone to oxidation.

- Q: What kind of material does the shockproof rubber cushion usually choose? What's the hardness?

- The air tightness of butyl rubber is the best of all the rubber, is its biggest advantage, it is mainly used for tyres, although there are shock absorbing function, but dynamic flex is not ideal.

- Q: Will rubber products fade?

- Rubber products will fade, is a rubber aging process, mainly due to external factors, temperature changes, the use of time, light, chemicals, external force and so on.

Send your message to us

Treadmill Golf Pattern PVC Conveyor Belt Treadmill Walking Belt for Gym

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords