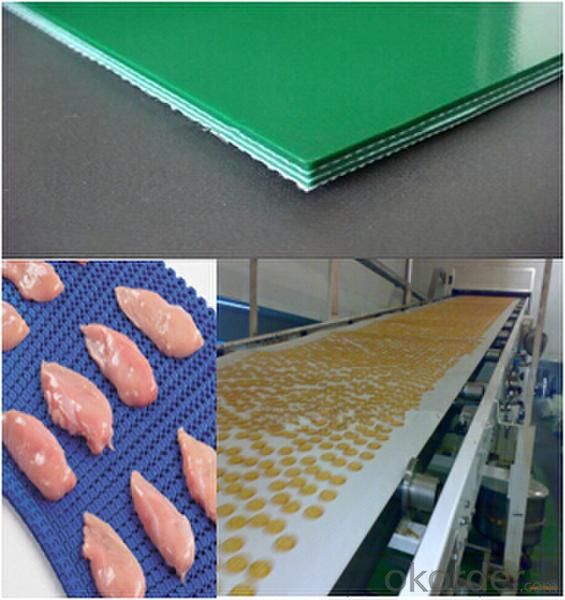

PVC PU Conveyor Belt Light Duty Green White Color Belting for conveyor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC PU Conveyor Belt Light Duty Green White Color Belting for conveyor

Specifications:

The PVC conveyor belts are manufactured using high quality material.It features largely in the high strength, stable conveyance performance. Besides, it is fire retardant, anti-static, shock resistant, wearable and corrosion resistant. Our food conveyor belts are FDA/USDA approved and most types also have USDA Dairy Approvedand support your HACCP concept.

Features:

1. Non-Conductive

2. Anti-Static

3. Resistant to fats, chemicals, oil fat and abrasion

4. Various surfaces with high, medium and low coefficient friction

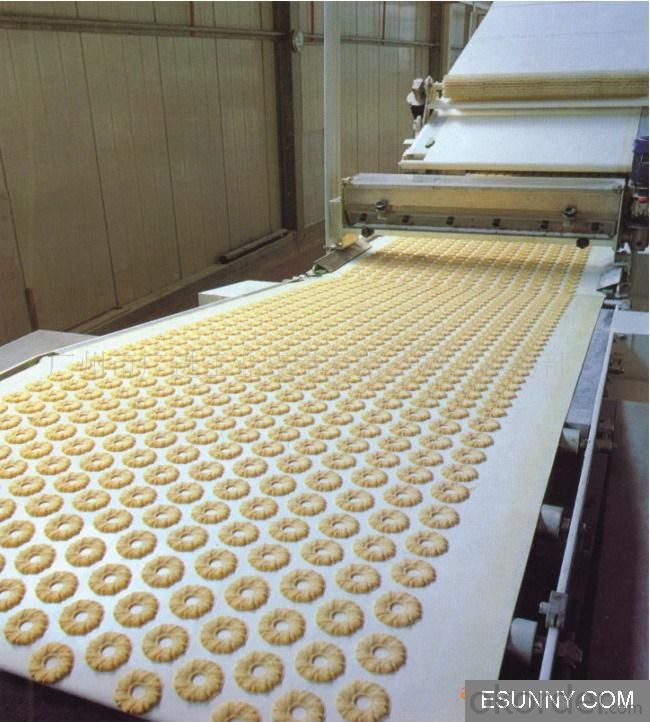

Application:

The belts are bets suited for varied applications like light weight conveyors systems, such as food processing industry, tobacco industry, textial, marble, wood, etc.

We can product various kinds of conveyor, and we also can customize with your requirement

PVC Solid Woven Conveyor Belt:

Ø Suitable for applications in dry conditions at a slope angle of no greater than 16 degrees.

Ø Cover thickness can be from 0.5 to 4mm.

Ø Nitrile covered PVG type

Ø Suitable for applications at a slope angle of less than 20 degrees, thickness can be 1 to 18mm.

Ø Resistance to wetness, slip, low temperature and wear resistance of the belt.

| Specification | Thickness (mm) | Color | Style |

| 1 ply fabric~1 ply p | 1 | green/white | plain |

| 1 ply fabric~2 ply p | 2/3/4/5 | green/white | skirt lace |

| 2 ply fabric~2 ply p | 2/3 | white/B.matt/green | diamond with small dot/grass |

| 2 ply fabric~3 ply p | 3 | green | diamond |

| 3 ply fabric~3 ply p | 4/5/6/7 | white/green matt | network wire |

| 3 ply fabric~4 ply p | 4/5 | green | diamond |

| 4 ply fabric~4 ply p | 9 | green matt | marble |

Above the form just list a part, we can product as your requirement, welcome to negotiate.

- Q: Is work in rubber products harmful to health?

- The raw material of rubber products is rubber compound, and the rubber compound has five components:Main rubber. Rubber main glue is not toxic.Reinforcing agent. Most of the reinforcing agents are not toxic.Softener. Is the most emollient mineral oils, high temperature volatile hazardous substances.Antioxidant. Some poisonous.Vulcanizing agent. The vulcanizing agent is generally sulfur, sulfur will release a high temperature sulfur dioxide, sulfur dioxide, sulfur dioxide, hydrogen sulfide gas three.

- Q: Process for producing rubber products

- The 1. main raw materials of rubber products with rubber as basic material, and rubber is grown in tropical, subtropical and the rubber tree bark collected by artificial cut.2. various compounding agents are auxiliary materials used to improve some properties of rubber products.3. fiber material (cotton, linen, wool and all kinds of man-made fiber, synthetic fiber and metal materials, steel wire) is used as rubber products skeleton material, in order to enhance the mechanical strength, limit product variant. In the preparation of raw materials, the ingredients must be accurately weighed according to the formula. In order to make the rubber and the complexing agent can mutually mixing, need to process material. Rubber to 60--70 C drying room drying soft gel, gel breaking and then cut into small pieces, with a massive agent. Such as wax, stearic acid, rosin and so on to be crushed. If the powder containing mechanical impurities or coarse screening to remove liquid such as pine tar, ancient Malone needs heating, melting, evaporation and filter impurities, complexing agent to dry or easy to agglomerate, when mixing if not dispersed vulcanized bubbles will affect the quality of the products

- Q: What about the Poisson's ratio and modulus of elasticity of three yuan ethylene propylene rubber (EPDM)?

- Three yuan ethylene propylene rubber is ethylene, propylene and non conjugated diene three yuan copolymer, began commercial production in 1963. The consumption of the whole world is 800 thousand tons every year. The most important feature of EPDM is its superior oxidation resistance, ozone resistance and corrosion resistance. Because three yuan ethylene propylene rubber belongs to polyolefin family, it has excellent curing property. Of all rubbers, EPDM has the lowest specific gravity. It absorbs large amounts of fillers and oils and has little effect on properties. Therefore, rubber compounds with low cost can be made.

- Q: How to make white rubber products do not yellow or delay yellowing time?

- The process of yellowing resistance is very complicated and involves many aspects, but the prevention of a certain point is not up to standard.Yellow change is mainly formed by aging. Controlling yellowing is the process of controlling aging.

- Q: What material is the rubber used in the tires?

- The main material of automobile tire is the most widely used rubber, natural rubber, polybutadiene rubber, styrene butadiene rubber, rubber and other Ding Ji. Early automobile tires are outside the tire structure, wherein the inner tube is made of rubber, rubber and tire cord fabric made by multilayer. Nowadays tubeless tires are mostly radial tyres. Radial tire early steel strengthened, with the development of chemical technology, replaced by synthetic fiber steel radial gradually by Kevlar and other lighter weight, higher strength.

- Q: What is a rubber accelerator? What role?

- Usage: This product is a kind of accelerator for chloroprene rubber, chlorinated polyvinyl chloride rubber, epichlorohydrin rubber and polyacrylate rubber. The utility model is suitable for metal oxide as a vulcanizing agent, especially when Magnesium Oxide and Zinc Oxide are used as vulcanizing agents. Safe operation, not easy to burn. This product is especially suitable for 54-1 (W) and general GN chloroprene rubber. It is easy to disperse, no pollution and no discoloration in the rubber. In the general product, the dosage is 0.25-1.5, in the 54-1 (W) chloroprene waterproof product, the dosage is 0.2-0.5 parts, and should be accompanied by 10-20 parts of lead oxide.Packaging and storage of 25Kg plastic paper composite bag, kraft paper bag or plastic container. Store in a cool, dry and airy place. Avoid the sun.

- Q: How can there be a crack in the rubber ring?

- In use, high temperature and exposure to sunlight in the air can cause aging and cracking of NBR

- Q: How do you remove the black dirt on the rubber?

- You should be rubber silicone, most of all is blackTry rubbing it with diluted alcohol.

- Q: How to distinguish between plastic products and rubber products, toys?

- There are several differences between plastic toys and rubber toys! First: from the taste can be divided, rubber flavor is relatively large, second: feel thick texture, plastic will not have any flavor, texture and weight are lighter!

- Q: What's the difference between natural rubber and three yuan ethylene propylene rubber?

- The electric property of natural rubber is a kind of non polar material, and it is a better insulating material. When the natural rubber vulcanization after the introduction of polarity factors, such as sulfur, accelerator, so that insulation performance.

Send your message to us

PVC PU Conveyor Belt Light Duty Green White Color Belting for conveyor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords