Rubber Conveyor Belt For Quarry And Mining Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rubber Conveyor Belt For Quarry And Mining Industry

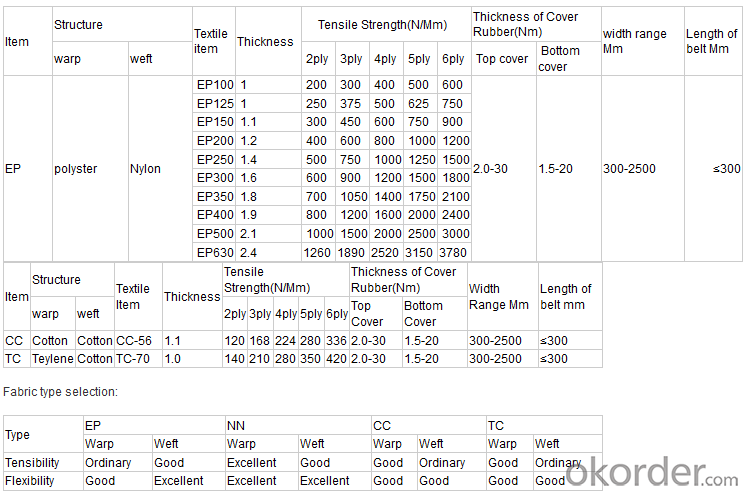

Description of Rubber Conveyor Belt

The product is made of Cotton/Nylon/EP canvas and finished through the process of assembling, vulcanizing etc, suitable for conveying materials that require a flame resistant and static conductive belts in power, chemical, light, metallurgical and grain processing industries, under the condition of flammable or explosive environment above coal mines.

The polyester conveying belt is also called EP conveying belt. Its framework material is the polyester canvas interwoven with meridian terylene and latitudinal polyamide fiber. It is characterized with excellent endurance, good water-resistance, no lowering of strength in humidity, mildewproof, and high load of initial models. It is applicable to convey materials in medium and long distance, with high-load, and at high speed.

Specification of Rubber Conveyor Belt

1) Fabric: Cotton, Nylon, Polyester

2) Width: 200mm-1800mm

3) Thickness: 4mm-20mm

4) T/S: 8Mpa-24Mpa

Pictures of Rubber Conveyor Belt

Pls contact me freely if any inquiry or questions,thank you!

- Q: How can the frictional properties of rubber improve?

- Because of its high elasticity and low modulus, the friction and wear properties of rubber are greatly affected by their physical and mechanical properties. The hardness of rubber is smaller, contacting with a rigid object, the real contact area is large, and the real size of the contact area is an important factor, so the friction rubber hardness, have more effect on the friction performance.

- Q: How can rubber and mould not be bonded when producing rubber products?

- Rubber is soft nature of the product, the draft (draft angle) is not to die. In other words, theoretical deduction is possible. However, the complex structure, a little larger, and often die adhesion is difficult to remove, and part of the solution can be solved with release agent.

- Q: How to distinguish between good and bad silicone rubber gasket?

- Silicone rubber gasket has a good elasticity, because the high elasticity mainly comes from the movement of the molecular chain of silica gel, so when buying silicone products, first look at the elasticity of silica gel products, so as to determine the quality.

- Q: Why is natural rubber a strategic material?

- Natural rubber can be divided into standard rubber (also called rubber), smoked rubber sheet, concentrated gum, white crepe, light colored film, skim rubber and dry film, is the most commonly used standard rubber and smoke film. Standard rubber is divided into a (SCR5), two (SCR10), three (SCR20), four (SCR50) four grades, divided into 1-5 smoke smoke film (RSS1-RSS5) five grades.

- Q: How are rubber wires processed?

- [summary] the main raw material is rubber, rubber products with various agents, as well as the fiber and metal skeleton material, the basic production process of rubber products including plastication, mixing, calendering, extrusion, molding, curing 6 basic processes.The processing process of rubber is mainly to solve the process of plastic and elastic contradictions, through various means of processing, the elastic rubber has become the plastic rubber, adding various in the preparation of semi-finished products, and then through the vulcanization is has semi-finished plastic and rubber products into high elasticity and good mechanical performance the.

- Q: What plastic rubber will not be subjected to oil (such as transformer oil) by quality (e.g., aging, dissolution)?

- The most essential difference between plastics and rubber is plastic deformation when plastic deformation occurs, while rubber is an elastic deformation. In other words, it's not easy to restore the original state after plastic deformation, and rubber is relatively easy. Plastic elasticity is very small, usually less than 100, while rubber can reach 1000 or more. Most of the molding process of plastics is finished

- Q: Can rubber products be injection molded and plastic injection functions?

- Rubber is an elastic polymer. Rubber can be obtained from the plant sap, can also be man-made, both have many applications and products, such as tires, washers, etc., has become an important economic crop. The cultivation of rubber is mainly concentrated in Southeast Asia, such as Thailand, Malaysia and Indonesia.

- Q: Is rubber flame retardant?

- Rubber itself is flammable, in the production process can be filled with some flame retardant material, it can reduce its flammability, but at the same time reduce its inherent good performance, such as abrasion resistance, elasticity, etc..

- Q: What about the smell of smoked rubber products?

- The corresponding type of rubber deodorant is one of good methods for removing it, or to reduce the degradation of various rubber acids produced in the processing or in the process of the use of alkoxy compounds, aldehydes, vinyl compounds, peroxide and sulfide odor of chemical additives, the smell if inhaled for a long time will stimulate the senses, give people uncomfortable feeling even harmful to the body, have two times of pollution to the environment, the chemical composition of different varieties of rubber and the resulting odor molecules are different,

- Q: What kind of rubber is suitable for waterproof aprons?

- One to do waterproof rubber ring, choose ethylene propylene rubber! The main sealing ring of fire ditch pipe is mainly made of ethylene propylene rubber!! Physical and chemical properties have corresponding national standards!

Send your message to us

Rubber Conveyor Belt For Quarry And Mining Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords