Belt Conveyor For Coal ,Sand Making

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Belt Conveyor for coal ,sand making:

Type | Capacity(m3/h) | Diameter(mm) | Motor power (kw) |

B500 | 25-143 | 500 | 1.5-3 |

B650 | 40-243 | 630 | 1.5-4.5 |

B750 | 75-500 | 630 | 2.2-7.5 |

B1000 | 140-770 | 800 | 4-11 |

B1200 | 200-980 | 1000 | 5-22 |

Usage of Belt Conveyor for coal ,sand making

1,Working Temperature: -25°C~+40°C.

2,Material Temperature: not exceed 50°C. Further measures will be taken for the special requirements of anti-explosion, water proof, anti-corrosion, heat and cold resistance.

3, Material Bulk Density: 0.5~2.5t/m3

4, Belt Width: 500/650/800/1000/1200/1400/1600/1800/2000/2200/2400mm

5,Driving Device: electric motor with reducer, electric roller, etc.

Advantage

1.Economical and practical

2.Effective to use bulk material transporting over long distance

3.Effective for those places that require wide range of paths to travel

4.Durable, dependable and low cost operation

5.Belt width range is 400 mm to 1200 mm

6.Capacity is from 30 ton per hour to 480 ton per hour

Packing & Delivery

In nude, delivery time according the client's quantities.

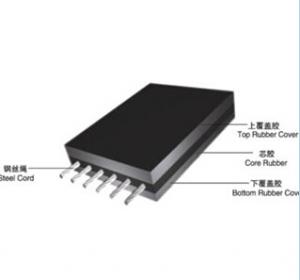

Picture of Belt Conveyor for coal ,sand making:

- Q: What's the application of ore shaker?

- [ore vibrating screen] advantages1, large processing capacity, high screening efficiency.2 、 the vibrator is lubricated by bearings, thin oil lubrication, and external block eccentric structure. The utility model has the advantages of large exciting force, small bearing load, low temperature, small noise, etc.. (bearing temperature rise less than 35 degrees).3, the vibrator whole assembly and disassembly, maintenance and replacement is convenient, greatly shorten the overhaul cycle. (it only takes 1~2 hours to replace the vibrator).4 、 the side plate of the screen machine adopts cold cold welding, no welding, high strength and long service life. The connection between the beam and the side plate is made of anti twist shear and high strength bolt. It is easy to replace without welding or cross beam.

- Q: What is vibrating screen?

- Vibrating screen meshPosition, ensure that the mesh size, mesh has a two-way bending vibration ripple, locked bending, two-way separated wave bending, flat bending, unidirectional corrugated bending, solid structure, used for mine, mine, construction, petroleum, glass factory, metal products industry, a special pig net crimped wire mesh.

- Q: What is the working principle of variable frequency vibrating screen?

- During the operation, the material is classified as a process of screening from high strength to high frequency and fine classification, so as to achieve the best effect of screening.

- Q: How does the mine vibration sieve do not do?

- This requires a specific look at the characteristics of your material, the screen is not net, may be too large sieve, or may be length is not enough

- Q: What is the working principle of a standard vibrating screen machine?

- To separate the HC base vibration of different size, and then transmitted to the base through the standard test placed on the base of the standard test sieve, sieve, sieve material that is less than the test particle surface mesh into the lower sieve, so the material composition and determination of particle size. The material in the test sieve can be effectively screened, graded and filtered.

- Q: How is the application of compound spring in vibrating screen?

- The utility model has the advantages of good stability, high load capacity, vibration isolation, noise reduction and the like.The utility model is more suitable for large-scale vibrating equipment in mines, coal, metallurgy and other industries.

- Q: How to install the vibrating motor (a vibrating motor) in the vibrating screen? Parallel angle?

- In addition there is a linear vibration motor vibration sieve is advanced, which is different from the ordinary vibration motor vibration motor, is a plate type vibration motor, the vibrating motor is arranged on the side of a shaker, which not only simplifies the structure of the machine and reduce the weight of the equipment, and improves the performance and technical parameters of screen, screen the relatively small volume, convenient maintenance, easy to process layout.

- Q: What are the damping springs on the vibrating screen?

- There are four kinds of vibration damping springs. Steel wire compression spring, rubber spring, composite spring and rubber air spring.1 、 steel wire compression springCompressed by steel wire, most of which are round, usually equal pitch, steel wire coil and ring in the middle of a certain gap, compression by external force will shrink.2. Rubber springThe rubber spring is made of natural rubber and is a high elastic body. The utility model has the advantages of waterproof, www.zhendong-shai , high temperature resistance, low noise, electric insulation, long service life, low cost, high resilience, etc..3, compound springThe composite spring combines the characteristics of the rubber spring and the steel spiral spring, and the material is also an elastomer combined with the two. Set the advantages of both as one, and also improve the shortcomings of both. The utility model has the advantages of good stability, high load capacity, vibration isolation, noise reduction and the like. The utility model is more suitable for large-scale vibrating equipment in mines, coal, metallurgy and other industries.4 rubber air springRubber air spring, commonly known as rubber air bag. The air is filled in the middle of the inner and outer rubber layers, and the elasticity of the spring is achieved by the compressibility of the air. This spring is seldom used on vibrating equipment.

- Q: What's the noise when the shaker is running?

- During vibration, relative sliding occurs between the spring end and the support. Because of the dry friction, the friction noise frequency is high and the sound is large, so the steel wire spring is changed into a rubber spring, and the impact of the screen body and the noise generated by the screen can be reduced to a certain extent. Tighten the bolts of each part of the vibrating screen to avoid additional vibration due to the looseness of individual parts. Replacing the metal sieve plate with the polyurethane sieve plate, because of the large internal resistance and small elastic modulus of polyurethane material, the use of polyurethane sieve plate can effectively reduce the noise produced by the impact of the material on the impact of the screen plate.

- Q: What are the precautions in the installation of vibrating screens?

- Daily maintenance of equipment:1) the initial operation of the equipment, the first 7 working days for the machine test run stage, please check the equipment every day, according to the test run stagePrepare the status and adjust the regular inspection time. The scope of inspection includes: tightening of fastening bolts of various parts (such as beam ring bolt, motor)Fastening bolts) and screen mesh (screen plate) is there fatigue or breakage?.2) shift (8 hours per class), the staff of fasteners (please ring bolts, bottom bolts) for fastening; 3) in strict accordance with the vibration of the motor manual regularly with reasonable amount of grease. The use of 3# the Great Wall lithium grease oil bearing, every 300 hours, please check and maintenance.4) vibration motor installation: vibration motor installation should use torque wrench, pay attention to each fixed bolt fastening can not be fixed onceFixed in place, the average number of times to tighten to the best state, the fixed bolt for class 8.8 high-strength bolts.5) the screen shall be inspected at each shift. It is suggested that the service life of the screen be determined by using the screen periodically during the critical periodReplace. Case: the service life of the continuous two screen mesh is 40 days. It is suggested that the screen mesh be replaced in 35 days.

Send your message to us

Belt Conveyor For Coal ,Sand Making

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches