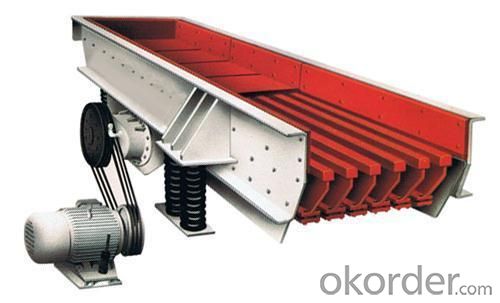

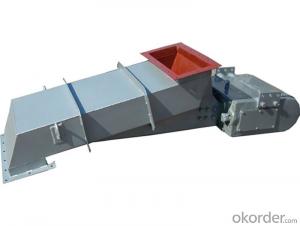

Grizzly Vibrating Feeder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Grizzly vibrating feeder:

pe | Outline size | Feeding size(mm) | Capacity | Vibration frequency | Double amplitude | Electric motor Power | |

Width(mm) | Length(mm) | ||||||

(t/h) | (time/min) | (mm) | (kw) | ||||

GZT1020 | 1000 | 2000 | 700 | 120 | 835 | 7~9 | 7.5 |

GZT0735 | 750 | 3500 | 500 | 105 | 835 | 7~9 | 7.5 |

GZT0740 | 750 | 4000 | 500 | 105 | 835 | 7~9 | 7.5 |

GZT0930 | 900 | 3000 | 600 | 120 | 835 | 7~9 | 7.5 |

GZT0940 | 900 | 4000 | 600 | 130 | 835 | 7~9 | 11 |

GZT0945 | 900 | 4500 | 600 | 135 | 835 | 7~9 | 15 |

GZT0950 | 900 | 5000 | 600 | 140 | 835 | 7~9 | 15 |

GZT1140 | 1100 | 4000 | 750 | 180 | 835 | 7~9 | 18.5 |

GZT1145 | 1100 | 4500 | 750 | 200 | 835 | 7~9 | 18.5 |

GZT1150 | 1100 | 5000 | 750 | 220 | 835 | 7~9 | 22 |

GZT1250 | 1200 | 5000 | 850 | 330 | 835 | 7~9 | 30 |

GZT1560 | 1500 | 6000 | 1200 | 700 | 835 | 7~9 | 30 |

Usage of Grizzly vibrating feeder:

Our feeder series have two types :vibrating feeder and liear feeder .Vibrating feeder series have two engines.Users can adjust vibrating frequency of feeder freely so as to completely control feeding speed of stone material and ensure smooth operation of production line. Linear feeder has feature of stable vibration,reliable operation and long service life ,can feed crushing machine continously and has primary sieving on materials.It is widely used in crushing and screening plants of mining ,construction materials ,silicate and chemical industry.

Feature of GZD / ZSW Vibrating Feeder

1. It can divide into two types: vibrating feeder and linear feeder.

-- Vibrating feeder series has two vibrating motors, so our customers can freely adjust the feeder vibrating frequency so as to completely control feeding speed of stone material;

--Linear feeder has features of stable vibration, reliable operation and long service life.

2. It can realize the continuously and uniformly feeding for the crushing machines, as well as can finish the coarse sieving on material.

Picture of Grizzly vibrating feeder:

- Q: The role of soft connection of vibrating screen

- The vibrating screen soft connection generally refers to the connection of inlet and outlet parts, common materials for canvas, rubber, silicone, polyurethane, because the screen high frequency vibration, and other equipment for flexible connection, carrying the material and damping effect.

- Q: Where is the thin oil shaker?

- The whole vibrator is assembled and disassembled, and the maintenance and replacement are convenient, and the overhaul cycle is greatly shortened. (only 1~2 hours changing the vibrator);

- Q: How does the material of the linear vibrating screen not move forward?

- Then there is the screen outlet is not tightened, so that the screen upturned, which can also cause material failure.

- Q: Soy milk filter is a good vibrating screen or a centrifuge?

- There's a special filter screen.

- Q: What are the factors that affect the measurement results?

- The workload refers to the quality of the screening unit at the time the material in the vibration sieve size; and the size of the screening efficiency is the most critical factor, the screening efficiency refers to after the screening and screening sieve weight products to the material contained in the aperture size is less than the granule weight ratio the percentage of. It is said that the extent and quality of the product screening screening operation.

- Q: How does rock powder vibrating screen work on mineral processing?.

- Winnowing screening is to solve the wet sieving sieving way of high water problems, through the difference of suspension speed of different level of material in the air flow to the screen, the screen has been widely used in water shortage area.

- Q: What kind of vibrating screen is used in the coal preparation plant?

- According to the raw materials, coal particle size composition, moisture and other factors, as well as the use (such as raw coal, large particle size classification, desliming, off the media, etc.) to determine.

- Q: How to use the drilling fluid vibrating screen and how to operate it?

- Amplitude adjustment: first open the hood, a special six angle wrench to loosen the eccentric block fixing bolt, the two ends of the motor with eccentric block angle adjustment, 60%~80% is appropriate, and then fixed bolt.

- Q: How do I change the strainer for the vibrating screen?

- Check again to see if any parts are not solid or out of place

- Q: What is the difference between an ultrasonic vibrating screen and an ordinary vibrating screen?

- The difference between screening materials: ordinary three yuan rotary vibrating screen can screen a variety of powder materials, and the sieve is divided into good effect. But in screening some, such as silicon carbide, Zong Gangyu, white corundum, cobalt powder, etc. in principle, it can be screened, but in the processing capacity and screening accuracy, it has not met the requirements. The ultrasonic vibration sieve exactly meets this requirement. Due to the installation of the ultrasonic transducer can be 220V or 110V, 50 Hz, 60 Hz power into high frequency 18 Hz, and then enter the ultrasonic transducer, the high-frequency electrical energy into mechanical vibration, the ultrafine powder material by ultrasonic acceleration strong, solving friction, produced in the process of screening drop, wedge such phenomena, improve screening accuracy and the processing quantity at the same time, since the net cleaning efficiency is significantly improved;

Send your message to us

Grizzly Vibrating Feeder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords