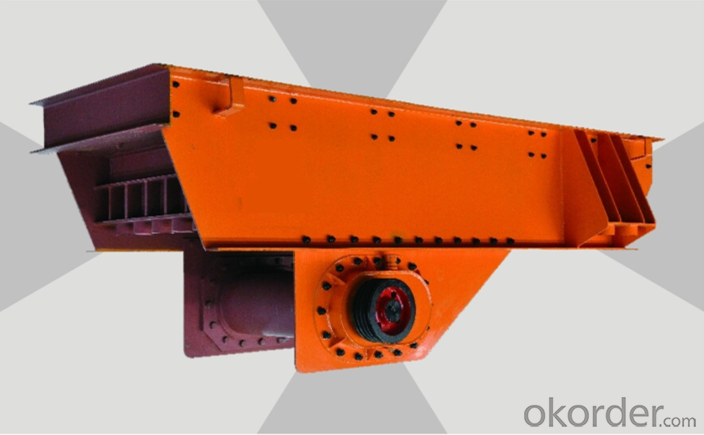

ZSW Vibrating Feeder,Mining Equipment, Feeder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Profile

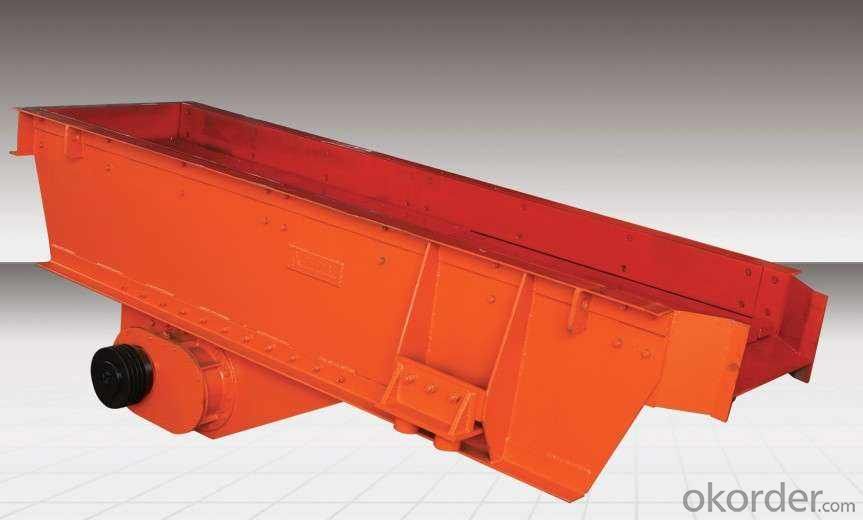

This series feeder is straight line vibration feeder, adopting vibration exciter mode, it has the characteristics of stable vibration, reliable operation and long service life. It can be used for continuous, even feeding of crusher machinery; Promote and improve the crusher machinery’s capacity and continuous working ability, make it has the ability of preliminary sieving capacity for materials. ZSW vibration feeder is usually used in the feed of jaw crusher. Widely used in mineral processing, building materials, water conservancy, chemical industry and other fields of crushing and screening combined equipment such as feeding and batching from crushing, coal preparation, screening, transportation, packaging machinery.

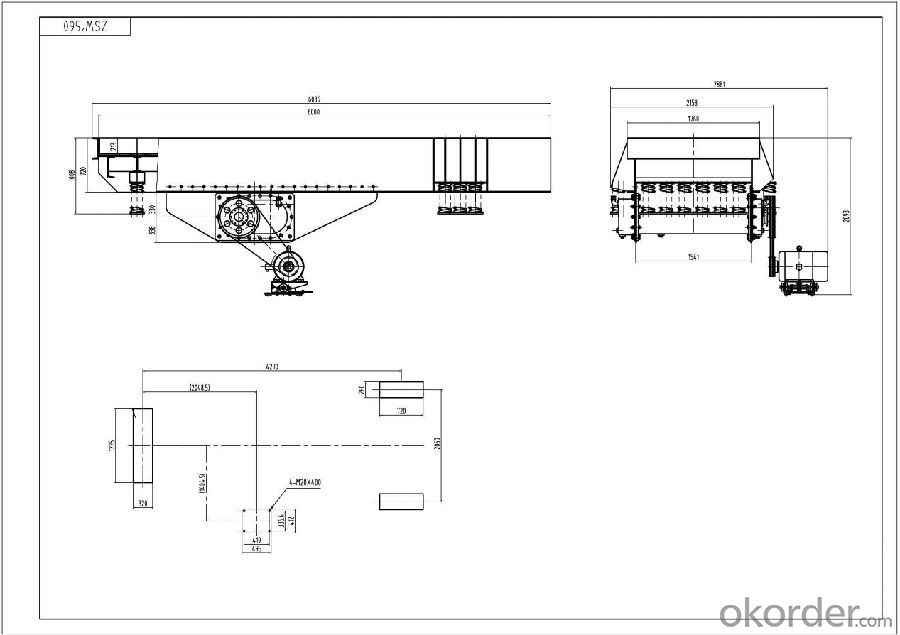

Overall Drawing

Technical Specification

Model | Max. Feed Size(mm) | Handling Capacity (t/h) | Power(kw) | Double Amplitude(mm) | Weight |

ZSW380*95 | 500 | 96-210 | 11 | 9 | 4.1 |

ZSW490*110 | 580 | 160-350 | 15 | 10 | 5.3 |

ZSW600*l30 | 800 | 400-560 | 22/30 | 10 | 7.5 |

ZSW600*l50 | 1000 | 460-615 | 30/37 | 9 | 8.7 |

ZSW600*l80 | 1200 | 600-1000 | 37/45 | 9 | 12.6 |

Function

The structure features of the double eccentric shaft exciter are adopted in ZSW vibration feeder to ensure that the equipment can withstand the impact of large pieces of material falling and has large feeding capacity. In the production process, the block and granular materials can be sent to the receiving device evenly, regularly and continuously from the storage bunker to prevent the feeding device due to uneven feed to encounter the system halted or crash problems; in the other hand, the service life of the equipment is prolonged. Feeder can be divided into steel plate structure and grate structure, the feeder which is steel plate structure is used in sand and stone production line, fed the material uniformly into the crushing equipment; The feeder of grate structure can be coarse screened for materials, making the system more economical and reasonable in preparation.

Feature

The vibration is steady and the work is reliable.

Special grid design to prevents material blocking.

The clearance of the grid is adjustable. Wear resistant parts are more enough to use.

Small materials are separated to prevent wear resistant be worn down from small materials, which can increase production.

Frequency control motor can be chosen for used to adjust the frequency, thereby changing the output, it is easy to control the feeding rate, and not need to start the motor frequently.

Working Principle

ZSW vibration feeder is mainly composed of vibration frame, spring, vibrator, motor vibration frame and motor. The vibrator exciter is composed of two special positions eccentric shafts meshed with gears and according to the mark to mesh the two gear when assembling. Two eccentric shaft is rotated by the motor drive, thereby the large synthesis straight excitation force be produced; Make the organism vibrate forcibly on the supporting spring, the material is driven by this vibration, sliding and throwing motion is carried out on the chute, so that the material moves forward to achieve the purpose of feeding. When the material passes through the sieve on the tank body, the smaller material can fall through the clearance of the screen, the effect of screening can be obtained without breaking through the next process.

Installation

The ZSW feeder shall be installed on the fixed foundation according to the required installation method. The wheels of mobile feeder should be wedged by triangular or braked by stopper before operation, so as to avoid sliding in work. When there are many feeder working in parallel, there should be a metre between the machine and the wall or machine and the another machine.

Before the use of the feeder, it is necessary to check the running parts, the belt buckles, the bearing devices and the protection equipment. The tightness of the tape must be adjusted to a suitable level before starting.

The feeder should start without load, after well running, the material can be fed. Operation after charging is prohibit.

When several feeder are connected in series and operation, should starting from the delivery end, sequential firing. After well running, the material can be fed.

When the belt deviation occurs in the operation, it should be stopped and adjusted, and must not be used reluctantly, so as avoid to wear edges and increase load.

The working environment and the temperature of the material to be sent shall not exceed 50 centigrade and below -10 centigrade. Materials containing acid base oils and organic solvents shall not be transported.

No pedestrians or passengers on conveyor belts.

Before stopping, the material must be stopped, and the belt can be stopped when the material is unloaded.

The motor of feeder must be well insulted. Do not pull and drag the cable of mobile feeder. The motor of feeder should be placed on ground.

The belt is not allowed to pull by hands when the belt is slipping, so as to avoid accidents.

FAQ

How much is the capacity of the equipment?

- Different specifications of equipment processing capacity will be different, the convention approved product of our company’s handling capacity is up to 1200t/h, it can also provide customized service according to the working conditions.

What brand does vibrator bearing use?

- Bearing adopts internal and abroad high quality brand. Regular co-operation branding is SKF, FAG (aboard brand).

What kind of vibrator lubrication mode is it?

- The vibrator adopts rare lubrication mode and the motor adopts high efficiency and energy-saving motor.

Does the equipment have coarse screening function?

- In the front of the sieving bar of this equipment is installed, and it can be carried out the coarse fraction to the ore.

Can the equipment withstand greater impact?

- The whole set of damping spring device is installed at the lower end of the feeding end of the equipment to withstand the impact of larger ore.

- Q: What problems should I pay attention to when buying a vibrating screen?

- In the purchase of vibrating screen, mainly to see the characteristics of your screening materials: particle size, how much to the screen, moisture content, viscosity, specific gravity, so you can calculate how much, what kind of models to meet your production requirements.

- Q: ZKR type of linear vibrating screen

- Working principle: multi layer powder linear vibrating screen is driven by double vibration motor, and the principle of vibration excited by motor is used. When the two motor synchronous and reverse rotation, vibration force of the eccentric block to produce the offset in the direction parallel to the motor axis, the vibration force and material combined effects of self gravity, the material in the sieve surface toss leap forward in a straight line, to achieve the reasonable matching of screen screening objective.

- Q: General ultrasonic vibration sieve for the purpose of how many nets, 100 of the target material does not add ultrasonic influence?

- The ultrasonic vibration sieve mainly aims at the screening of ultra fine powder materials and some materials with adsorption, sticky net, electrostatic and light weight

- Q: Why are the vibrating motors installed in different locations?

- The internal structure of the vibrating motor is the same as that of the ordinary motor. The main difference is that the vibration motor is equipped with a set of adjustable eccentric blocks at each end of the rotor shaft. The centrifugal force generated by the high-speed rotation of the shaft and the eccentric block is used to obtain the exciting force. The vibration motor is more reliable than the ordinary motor in mechanical and electrical aspects.Similarly, the power levels of the vibration motor rotor shaft than the same class of ordinary motor shaft much more thick. This is the main difference in order to meet the requirements of the actual working conditions.

- Q: What's the noise when the shaker is running?

- During vibration, relative sliding occurs between the spring end and the support. Because of the dry friction, the friction noise frequency is high and the sound is large, so the steel wire spring is changed into a rubber spring, and the impact of the screen body and the noise generated by the screen can be reduced to a certain extent. Tighten the bolts of each part of the vibrating screen to avoid additional vibration due to the looseness of individual parts. Replacing the metal sieve plate with the polyurethane sieve plate, because of the large internal resistance and small elastic modulus of polyurethane material, the use of polyurethane sieve plate can effectively reduce the noise produced by the impact of the material on the impact of the screen plate.

- Q: How many methods do you use to fix the screen surface of vibrating screen?

- Hook hook tension cable tension: refers to the screen or into a hook or end plate thin steel plate and rubber pad to screen peripheral edge wrapped into a hook, hook and fixed by bolts. The former is suitable for woven screen or sieve plate with thickness less than 6mm, which is suitable for small diameter of screen.

- Q: How to change the screen of vibrating screen?

- With a soft hammer knock around uniform beam, then the copper nut. The change of mesh is completed. IfIn the process of changing the screen of the vibrating screen, the female net frame and the movable plate are taken off, and the moving hole must be noticed when it is loaded backThe plate must indeed be inserted into the flange of the underside of the grid.

- Q: SZZ self centering vibrating screen assembly, who has?

- Xi'an Jincheng vibration is the professional vibrating screen, vibrating screen detector more time, can see on the website

- Q: How to choose eccentric block for direct axis eccentric block vibrating screen

- The vibration motor is an important part of vibrating screen, vibrating motor manufacturers too much, and many manufacturers are small products, although the production is the same type of motor, but with the motor shell are different, different, in fact the enterprise production of motor to meet with the following conditions can be. So, let's look at how to find the vibration motor that is suitable for vibration screening.

- Q: How can eccentric wheels be justified only if a vibrating screen with one eccentric wheel is installed?

- The eccentric wheel frame is often crack, you may consider a symmetrical arrangement of two, the total mass is half of the original quality, also should consider the change often split components of materials, should be soft and not easy to crack the material, the round to crack place.

Send your message to us

ZSW Vibrating Feeder,Mining Equipment, Feeder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords