Mining Vibrating feeder,vibration feeder with motor

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

- Option:

- GZG403 GZG503 GZG903 GZG1003 GZG1255 GZG705 GZG905 GZG1005 GZG1253

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

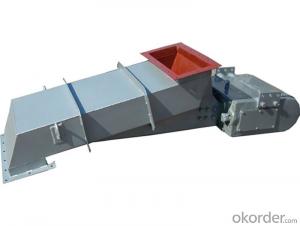

Mining Vibrating feeder,vibration feeder with motor

Introduction Overview of Mining Vibrating feeder with motor:

Mining Vibrating feeder with motor is a new energy-saving universal feeding equipment. The machine adopts the new type vibration motor as vibration source, often matching with vibrating conveyor, vibration sieve, bucket elevator, crushing and so on.

Application of Mining Vibrating feeder with motor:

Mining Vibrating feeder with motor widely used in metallurgy, mining, coal, electricity, building materials, chemical industry, machinery and other industries.

Working principle and structural features of Mining Vibrating feeder with motor:

The process of feeding is achieved by using the special vibration motor or two motors to drive the exciter to power the feeding trough along the oblique direction for periodic linear reciprocating vibration. The coal in the tank is thrown up, and moves forward according to the parabola, throwing and falling in an instant. Due to the continuous excitation of the excitation source, the trough is continuously vibrating and the coal is moving forward for giving materials.

Advantages of Mining Vibrating feeder with motor:

1.The structure is simple and compact, and the design is reasonable;

2. Convenient in operation and maintenance, low operating cost;

3.Feeding continuous uniform;

4.Low noise, is conducive to improving the working environment;

5.Energy saving: low power consumption, high power factor;

6.Stable amplitude, reliable operation, strong adaptability to various materials;

7.The material trough wear is small, the service life is long.

Technical parameter table of Mining Vibrating feeder with motor:

Model | Groove size width × length × height(mm) | Productivity(t/h) | Maximum feed size(mm) | Double amplitude (mm) | Vibrator model | Rated current (A) | Power (kw) | Total Weight (kg) |

GZG403 | 400×1000×200 | 30 | 60 | 4 | ZG405 | 2×0.73 | 2×0.25 | 163 |

GZG503 | 500×1000×200 | 60 | 60 | ZG405 | 2×0.73 | 2×0.25 | 202 | |

GZG703 | 700×1000×250 | 120 | 80 | ZG415 | 2×1.95 | 2×0.75 | 414 | |

GZG903 | 900×1500×250 | 170 | 80 | ZG415 | 2×1.95 | 2×0.75 | 605 | |

GZG1003 | 1000×1750×315 | 250 | 100 | ZG420 | 2×2.71 | 2×1.1 | 813 | |

GZG1253 | 1250×2000×315 | 320 | 100 | ZG432 | 2×3.51 | 2×1.5 | 1072 | |

GZG705 | 700×1000×250 | 120 | 80 | 6 | ZG612 | 2×1.66 | 2×0.75 | 307 |

GZG905 | 900×1500×250 | 160 | 80 | ZG612 | 2×1.66 | 2×0.75 | 577 | |

GZG1005 | 1000×1750×315 | 220 | 100 | ZG618 | 2×2.97 | 2×1.1 | 817 | |

GZG1255 | 1250×2000×315 | 270 | 100 | ZG625 | 2×3.84 | 2×1.5 | 1077 |

Maintenance of Mining Vibrating feeder,vibration feeder with motor:

1.During the work, should pay attention to whether the plate is smooth, such as abnormal operation or abnormal sound, should immediately stop and check;

2.The vibrator should be filled once a month 3# lithium grease lubrication, the bearing should be checked about degree of wear every year. If necessary, replacement of maintenance timely;

3.should often check the connection parts of the fastening bolts are loose, should promptly eliminate hidden dangers.

- Q:How to choose crushing equipment suitable for its own ore material?

- Attention should be paid to the size and production capacity of crushing equipment, whether it is what it needs

- Q:Which God knows, hammer crusher, according to the material into which there are several categories?

- Tangential feed -- from tangential direction is fed into the crushing chamber, the common good, not only crushed grain, also crushed small cake and chopped stalk and forage.

- Q:The opening process of press filter from feeding to discharging is described briefly

- Start and close the filter press.Open the feed valve.Starting feed pump.Control feed pressure or time, or two at the same time, to the set value, stop feeding.Close feed valve.With diaphragm extrusion equipment, start the diaphragm extrusion pump, correctly open the valve of each extrusion system, control the extrusion pressure, and then stop the extrusion after the setting value.Slow release of extrusion pressure, generally to about 7bar, stop pressure release.

- Q:What's the simplest ore radio to do?

- 2AP9 diode is a 600 ohm above the earplug foil 65 cm long 2 cm wide kraft paper a 70 cm long 3 cm wide and 3 meters to a copper wire wrapped in kraft paper in electric wire and copper wire tin foil wrapped in kraft paper outside the 3 meter long wire peeling exposed around 1 meters above the other foil one end is connected with the grounding wire and radio headset diode parallel diode cathode copper wire electrode tap water pipe is connected with a tap water pipe line lamp is very simple and don't pay attention to the leakage

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mining Vibrating feeder,vibration feeder with motor

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

- Option:

- GZG403 GZG503 GZG903 GZG1003 GZG1255 GZG705 GZG905 GZG1005 GZG1253

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords