GFS High-Amplitude Vibrating Screen,Mining Equipemnt,High-Frequency

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Profile

GFS high-amplitude vibrating screen is a kind of heavy-intensity circular vibrating screen which is produced by our company, what’s more, which has been widely applied to classifying the materials which have different particle sizes. The whole equipment is composed of multiple segments, therein, every segments is the independent vibrating units, as a result, the equipment has small vibration quality and unlimited moisture in the feeding materials, what’s more, due to the non-blocking screening, strong screening capacity and large processing quantity, the equipment is especially suitable for the deep screening of 6mm(above)wet materials.

Structure features

It is convenient to be installed with small repairing quantity and low operation costs.

There is no screen clogging phenomenon with high screening efficiency.

It has high vibrating amplitude, low frequency and small failure load.

The material flow can be adjusted according to the actual demands, therefore, it can be operated reliably.

It has simple structure, attractive appearance and favorable dust-proofing effect.

The protective devices are installed on the terminal of vibration exciter and the connection parts, therefore, it can be operated safely.

The screening performance is affected significantly by various factors such as equipment capacity and angle of inclination, in which the performance can be measured by screening efficiency and flux of the product.

Flux is defined as the amount of a desired component (undersize material) that has carried over the screening media from the feed per time per unit area. Screening efficiency is expressed as the ratio of the amount of material that actually passes through the aperture, divided by the amount in the feed that theoretically should pass. Commercially perfect screening is considered to be 95% efficient if the process is operated with appropriate feed concentration and size particles. Generally, a suitable particle size difference between sieving and feed should be no more than 30%. High screening efficiency can reduce the qualified gain content in cyclic loading and screening and thus increasing the processing capacity of the mill.

The equipment capacity is almost directly proportional to screen width. This means that by increasing the length, there will be additional chances for passage, and will usually lead to increase in transmission and efficiency. In general, the standard size of screen length should be two to three times the width.However, certain special situations such as restricted space may require a different design.

Angle of inclination can be designed based on the desired mineral grain. For example, wet sieving angle is generally around 25 ± 2 ° for concentrator. Increasing the slope of a screen will effectively reduce the aperture by the cosine of the angle of inclination. At the same time, the materials also move across the screen faster which leads to more rapid stratification. However, the performance tends to decrease after a certain point since the slope of the deck is too high and most particles will remain on the oversized stream instead of passing through the aperture, thus, lower flux is yielded.

.

Technical specification

Model | Screen specification | Leaning angle of screen(°) | Screen Size (mm) | Vibrational frequency (Hz) | Amplitude (mm) | Size of input granularity (mm) | Handling capacity (t/h) | Motor power (KW) |

GBS-1530/2 | 1.5*3.0 |

20~27 |

5~50 |

12.2 |

5~12.5 |

≤300 |

90~255 | 7.5×2 |

GBS-1545/3 | 1.5*4.5 | 7.5×3 | ||||||

GBS-1845/2 | 1.8*4.5 | 150~450 | 11.0×2 | |||||

GBS-2060/3 | 2.0*5.7 | 200~550 | 11.0×3 | |||||

GBS-2565/4 | 2.5*6.5 |

300~650 | 11.0×4 | |||||

GBS-2582/5 | 2.5*8.2 | 11.0×5 | ||||||

GBS-25100/6 | 2.5*10.0 |

11.0×6 | ||||||

GBS-30120/6 | 3.0*12.0 | 350~680 | ||||||

GBS-35100/6 | 3.5*10.0 | 420~750 | 22.0×6 | |||||

GBS-40100/6 | 4.0*10.0 | 450~850 | 30.0×6 | |||||

GBS-50125/8 | 5.0*12.5 | 550~950 | 37.0×8 | |||||

Notes: The processing capacity is the reference value which is calculated according to | ||||||||

The foregoing attached table shall only be used for reference. The actual application shall be appropriately modified according to customers requirements.

Working principle

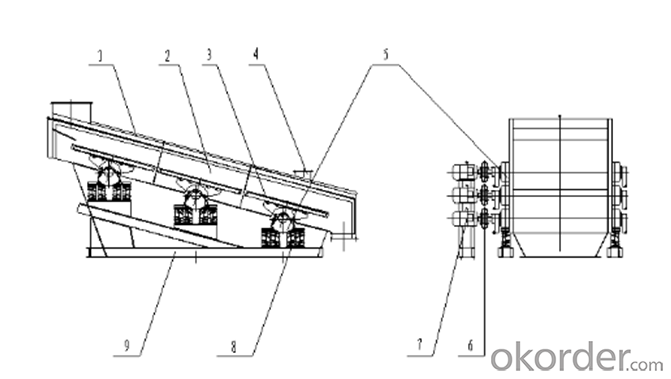

1. Sealed cowling

2. Straining box

3. Sieve tray

4. Dust extraction

5. Exciter

6. Flexible connection device

7. Motor

8. Damping spring

9. Cork bottom

Structure of exciter

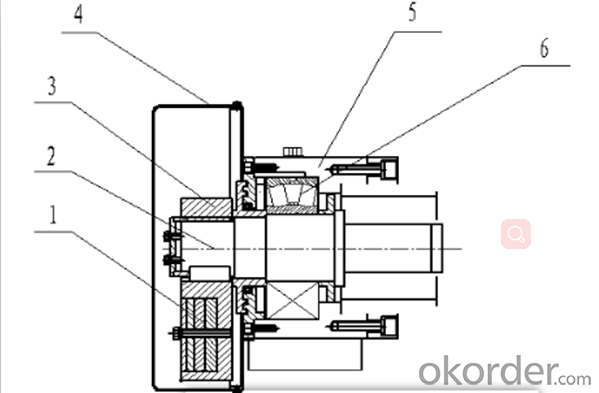

1. Balancing weight

2. Axis of rotation

3. Eccentric block

4. Protective cover

5. Bearing house

6. Bearing

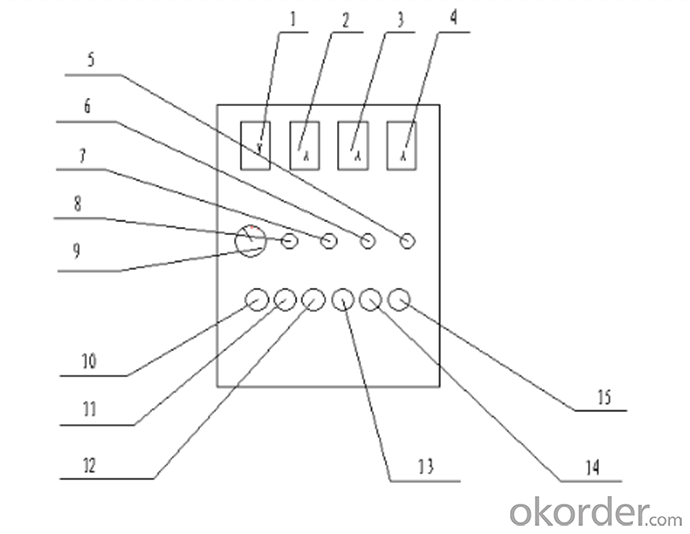

1. Voltage meter

2. Ampere meter(1)

3. Ampere meter(2)

4. Ampere meter(3)

5. Fault indicating lamp

6. Indicator(1)

7. Indicator(2)

8.Indicator (3)

9.Alternative switch

10. Starting(1)

11. Stop(1)

12. Starting(2)

13. Stop(2)

14. Starting(3)

15. Stop(3)

New development

Screen improvements

The research on high-amplitude vibrating screens has led to new developments in the field which enhance the operation and performance of the equipment. These new developments include the stacking of up to 5 individual screen decks placed on top of the other and operating in parallel. A divider system splits the feed slurry to each stack sizer screen, then to each screen deck on the machine. Each screen deck has an undersize and oversize collection pan which will respectively go into their common outlet. The stacking of the machines thus allows more production while using less space. Another new development is the fabrication of Polyweb urethane screen surfaces that have openings as fine as 45 µm and open areas from 35% - 45%. This leads to the screen being able to separate finer particles. The screens can be used for both wet and dry applications and urethane formulation is still an ongoing process. Thus, research and development is still being invested in high frequency screening equipment to improve the overall separation efficiency and also to lower costs.

Mechanical part modifications

To further optimize the performance for high-amplitude vibrating equipment, a "variable speed" hydraulic vibrator is being developed and used to drive the screen decks. It utilizes fluid hydraulic force which then can be converted into rotary power in order to generate high frequency vibration. This modification allows equipment to operate at higher frequency range, up to 8200 RPM, compared to the conventional electric vibrators. Besides that, the induced vibration also creates an excellent condition for separating finer particles and improves the contacting probability for the materials. Another variation that could be applied to the equipment is the "rotary tensioning system’, in which it helps to provide a quicker screen media change. Therefore, multiple applications can be achieved by single equipment, as with different size of feed material can be deal by replacing screens in a very small downtime. Hence, it improves the economic benefits of plants.

FAQ

What’s the difference among the high-amplitude vibrating screen and other vibrating screens?

Comparing with other vibrating screens, the high-amplitude vibrating screen has a essential difference in the structure of vibrating screen. In terms of the common vibrating screen, the whole straining box drives the sieve tray vibrating. On the contrary, the high-amplitude vibrating screen not only has sieve tray vibrating and the box straining is not involved in vibrating, but also the high-amplitude vibrating screen has so many vibrating units.

Where do the high-amplitude vibrating screen be used in ?

The high-amplitude vibrating screen is used to handle the materials which has a large viscosity and high water cost. Because the amplitude of the high-amplitude vibrating screen is high, it has a good efficiency to handling the materials.

What’s the common type of the high-amplitude vibrating screen?

Generally speaking, the sieve tray adopts bars. The sieve tray has the function of self-cleaning, which can reduce phenomenon that the hole in the sieve tray is blocked.

- Q: What is the purpose of using a vibrating screen?

- Many industries do not need vibrating screens, which is the inevitable result of the improvement of living standards and social standards.

- Q: Vibration motor and vibration sieve, why use C3 or C4 clearance bearings and use?

- Because the greater the clearance of the bearing, the lubrication of the vibrating screen can be guaranteed, the general vibration screen bearing room wearing parts, large clearance can also increase the bearing life.

- Q: What's the use of a frame type mud shaker?

- The flat shale shaker is one of the most popular oil vibrating screens, which can be widely used in drilling operations under different conditions. The product usually consists of 2 to 3 layers of stainless steel mesh cloth bonded to the metal lining of the opening. At the same time, the screen is provided with a special rubber stopper to repair the damage of the mesh surface, thereby effectively saving time and reducing production cost.

- Q: Selection is good or sub ballast drum sieve shaker.

- Because the material rolls and rolls in the drum, the material stuck in the sieve can be ejected to prevent the screen from clogging. The principle and structure of roller screen sand machine, drum screen and roller screen are almost the same.

- Q: What is the relationship between the transmission position of the linear sieve and the motor mounting angle?

- Note: the motor angle is bigger, the material runs faster, the amplitude is low, suitable for conveying, the angle is too small, will change the transmission direction, the material does not advance or slow; attention to these two main factors in the self-made vibration sieve, of course, like structure, screen installation can not be ignored. Hope to be of help to you

- Q: What are the accessories of high efficiency heavy vibrating screen?

- The utility model relates to an efficient heavy vibrating screen, which is composed of four parts with simple structure and clear structure.1. Vibration source: vibrating motor or ordinary motor plus exciter.2. Sieve body: including side plate and crossbeam, between use high strength bolt or ring groove rivet link.

- Q: What kind of material is the vibrating screen generally?

- Generally 316L, according to screening materials selection screen

- Q: What are the lubrication characteristics of the vibrating screen? What are the requirements for the lubricating oil?

- Sodium base grease is made from natural fatty acid sodium soap, made of mineral oil or synthetic thickener of lubricating oil, and run along the synthesis of sodium base grease is made by the synthetic fatty acid soap, made of mineral oil thickener of.

- Q: What should be paid attention to when using the motor on the vibrating screen?

- We must ensure that the mounting surface paint and no debris, ensure vibration motor feet clean.Warning! The motor shall not be welded on the mounting plate when the vibration motor has been installed and wired. Welding can cause vibration, motor winding and bearing damage.

- Q: Characteristics of high frequency vibrating screen of high frequency vibrating screen

- The screen of the high frequency vibrating screen has three layers, and the flexibility of each layer is different. The bottom layer that we call it the support network, are always made of steel wire rope core polyurethane paving composite support; online network, composed of stainless steel wire woven; finally this layer is in direct contact with the material needs to work, is called work network. The left and right sides of the screen of the high frequency vibrating screen can be easily loaded and unloaded, and the tension degree is not difficult to adjust. Buffer plate design is also a major bright spot, into the material in the buffer action, the pulp will be distributed evenly, will not directly impact the screen, extending the screen life.

Send your message to us

GFS High-Amplitude Vibrating Screen,Mining Equipemnt,High-Frequency

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords