DZS Linear Vibration Screen,Mining Equipment,Screen

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production

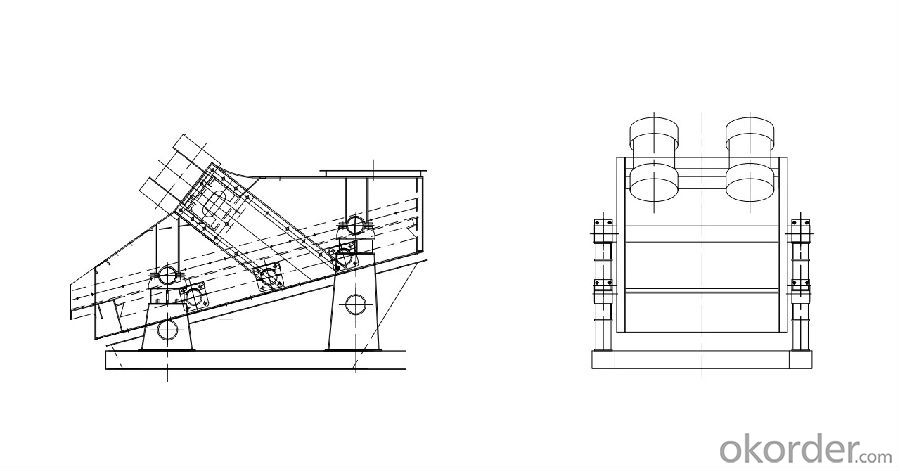

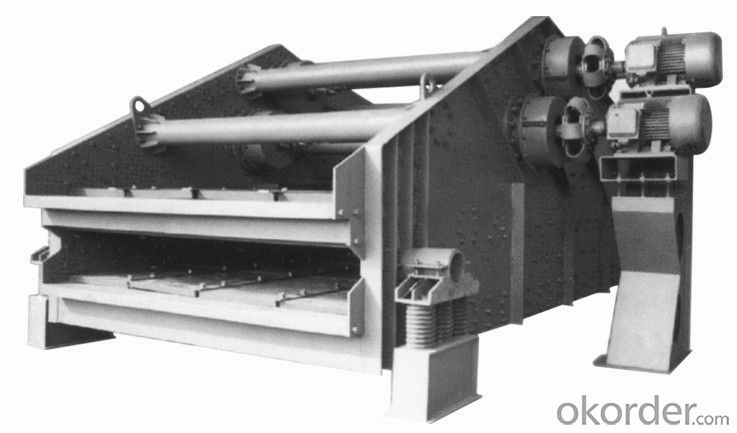

DZS linear vibrating screen is composed of excitation device, screen box, dust mover, blanking hopper, damping device and foundation. As a kind of new-type screening equipment, it is widely applied to classifying the large-block materials, the medium and small particles substances in the mining, coal, electricity, metallurgy, building materials, fire-resistant and other industries.

Structure features

It has small volume and large screening capacity.

Due to the light weight, it is convenient to make installation and process arrangement.

Due to the less energy consumption, it can save lots of resources.

It only need low price with few spare parts.

It has simple structure and beautiful appearance.

The screen cloth is assembled by the small pieces, therefore, it is extremely simple to make replacement.

Structural component

The DZS linear vibrating screen is mainly made up of straining box, deck base, screen, vibration motor, bed box of motor, damping spring,support and other parts.

Straining box: the straining box is welded by various thickness steel plate, which has a definite strength and rigidity. It is the main component of the DZS linear vibrating screen.

Deck base: the deck base is made of wood which includes pine or low-deflection wood, which aims to keep the screen smooth. By means of this way, it can reach normal screening.

Screen: the screen is mainly made of several materials, such as mild steel, brass, tungsten bronze, stainless steel and others.

Vibration motor: the usage and maintaining methods refers to the usage instruction of vibration motor.

Bed box for motor: the bed box is used to install the vibration motor. Before the bed box for motor is used, the bolts on the bed box must be fasten tightly. Especially, the bolts should be screw tightly again and again which aims to prevent the accident causing by loose bolts during the three days before.

Damping vibration: the damping vibration is used to prevent the trembling to the ground. In the meanwhile, it can support the total weight of the straining box. During the installation, the damping spring must be set vertically on the ground.

Support: the support is made up of four pillars and two box irons which is used to support the straining box. During the installation, the pillars must be set vertically on the ground. The box irons under the two pillars must be parallel.

Instruction

The design of the DZS linear vibration screen is ingenuous. Also, it is convenient to assemble. The DZS linear vibration screen can be operated by simple one operator.

Comparing with other brand manufacturer, it has a quite big screening area and high-efficient disposal capacity.

The unique structural design of screen is convenient and simple to change the screen(it will spend 3-5 minute on changing the screen). what’s more, all kinds of screens are suit to this design, such as nylon, special purpose nylon and PP net.

The main net support the thin net totally. Thus, the thin net can have a long service life. And, it can reduce the consumable materials.

Function

By means of the installing heavy hammer installed on the up and down end of motor shaft, the rotated motion of motor is changed into three dimensional motion which includes horizontal, vertical and inclined motion. And then, the motion is transferred to sifter. If the phase angle of the up and down part of heavy hammer is changed, it can change the advanced direction of raw material.

Technical specification

Model specification | ZSG-1020 | ZSG-1030 | ZSG-1530 | ZSG-1540 | ZSG-1550 | ZSG-1850 |

Screening capacity (t/h) | 10-200 | 15-250 | 20-350 | 25-400 | 30-500 | 30-500 |

Feeding degree(mm) | ≤250 | ≤350 | ≤400 | ≤400 | ≤400 | ≤400 |

Screen area(㎡) | 2 | 3 | 4.5 | 6 | 7.5 | 7.5 |

Screening Mesh size(mm) | 3-50 | 3-150 | 3-200 | 3-200 | 3-200 | 3-200 |

Vibration frequency (r/min) | 960 | 960 | 960 | 960 | 960 | 960 |

Double vibration amplitude (mm) | 8-12 | 8-12 | 8-12 | 6-10 | 6-10 | 6-10 |

Motor power(KW) | 2.2*2 | 2.2*2 | 3.7*2 | 3.7*2 | 5.5*2 | 7.5*2 |

The foregoing attached table shall only be used for reference. The actual application shall be appropriately modified according to customer’s requirements.

Preparation before installation

Firstly, the operator must check the label to assure whether if it conforms to the requirement.

The operator must check the surface of the motor to assure that there exists no damage and deformation.

The operator must check all the fastener on the motor to avoid loosing.

The operator must check the power source to assure whether if it is lack of phase. Then, the DZS linear vibration screen must be operated five minutes with empty load.

The operator must check that whether if the rotation is flexible. If the running is abnormal, it need to be excluded.

Installation and adjustment

The electrical machinery must be fastened on the surface tightly. Also, the surface of the installing surface must be smooth and tide.

The electrical machinery can be installed horizontally.

The exciting force can be adjusted

The electrical machinery should have reliable ground connection. Inside the electrical machinery, it is installed with ground connection device. On the down-lead end, there exists remark. Also, it can make use of footing firm bolt to connect the ground.

FAQ:

Which vibration model do the DZS liner vibration screen have?

The liner vibration screen has following vibrating type, such as up vibration type, down vibration type,side vibration type and embedded chellops type. In according to various working condition, the required vibration type can be chose.

Which vibrating source do the DZS liner vibration screen have?

Some liner vibration vibration screens adopt vibrating motor and some of them adopt box-type vibrator. Also, the embedded chellpops vibrator. There exists various types can be chose.

What’s the sieve plate is made of ?

The sieve plate can be made of high manganese steel mesh grid, PU sieve plate, high-frequency wear-resisting welding sieve plate, bar-type sieve plate and other types. It is depended on working conditions.

- Q: What is the structure principle of sweet potato starch vibrating screen?

- The moving angle of the material on the screen surface can be changed by the phase angle of the upper section and the lower end, so that the material passes through the screen rapidly and achieves the purpose of sieving

- Q: OK, where can I get the shaker dust collector?

- The device consists of dust catcher, fan, pLc automatic pulse blowing system, hanger, inspection door, sealing soft curtain and so on. The use of vibrating screen dust collector can avoid the dust flying everywhere and pollute the environment, and contribute a lot to the protection of the earth environment. With the increase of the surface of the filter bag dust, knife resistance value reaches a predetermined value, the pressure sensor to the electronic control box indicating signal, by pLc automatic control system for automatic pulse jet bag was blowing, attached to the bag on the dust shake off, after unloading ash pipe directly to the sealing belt. That is to keep the filter bag good filter performance, and no two dust.

- Q: Why is the efficiency of the high frequency linear vibrating screen better?

- High frequency vibrating screen is in accordance with the different speed of vibration motor vibration to the classification, the motor speed is higher, the vibration frequency of high frequency vibrating screen is higher, is divided into two kinds, one is the ordinary high frequency linear vibration sieve, vibration motor speed is 1500 rpm,

- Q: How many Xinxiang vibrating screens are there now? How many are there on a scale?

- I feel a lot, but I still listen to those.

- Q: The vibration of the motor seat of the vibrating screen is cracked when it is used. It is He Yuanyin

- Rubber spring has the advantages of small size, but large stiffness, good vibration isolation performance, the disadvantage is that it is not suitable for large amplitude, large dynamic load. Because of the large amplitude of the vibrating screen, the cylindrical helical spring is usually used as the vibration isolation device.

- Q: What kind of material is the vibrating screen generally?

- Generally 316L, according to screening materials selection screen

- Q: How do I clean the shaker?

- According to different screening materials, cleaning methods are different, you can choose to use a brush, you can also choose to rinse with water.

- Q: How about paint vibrating screen?

- We all know that different types of vibration, its working principle and design concept is to be quite different, such as mining vibrating screen in ore mining production line and a paint shaker was used for screening of coatings, nature is like tannangquwu.

- Q: How to improve the production capacity of ball mill? What safety problems should we pay attention to during the operation of the vibrating screen?

- Material from the feed devicefeedair evenly into the mill screw shaft first warehouse, the warehouse has stepped lining board or corrugated liner, built in different specifications of steel tube to rotate the ball to a certain height, the centrifugal force generated after the fall, pounding and abrasivematerials. When the material reaches rough grinding in the first bin, it enters the second warehouse through a single partition board. It is equipped with a flat lining board with steel balls in it and further grinding the material. The powder is discharged through the discharging grate plate to complete the grinding operation. <br> <br> Hengchang Metallurgical Building Material Equipment Factory in large-scale production at the same time, to improve the yield of ball mill was studied in <br> <br> is a direct way to improve the yield of ball mill has 3 kinds: <br> <br>1. mill is set at front of the crushing machine; <br> improved <br>2. ball mill grinding system, improve grinding efficiency; <br> <br>3. equipped with high-efficiency powder machine.

- Q: How many methods do you use to fix the screen surface of vibrating screen?

- Wedge clamping wedge pressing: refers to the use of wedge to sieve surface is fixed on the frame of the mode of vibration sieve. The pressing method is suitable for the punching sieve plate and the slit screen surface.

Send your message to us

DZS Linear Vibration Screen,Mining Equipment,Screen

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords