Rubber Conveyor Belt

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Plastic packaging |

| Delivery Detail: | 30days |

Specifications

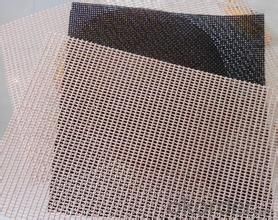

1. EP conveyor belt, steel cord belt, HR conveyor belt,chevron belt,etc

2. thickness: 3mm to 50mm .

3.width: 300mm to 2.2m

We can provide a huge gamut of superlative industrial conveyor belts that are used in varied applications with DIN22102.

Width : 400 mm to 2600 mm.

Length : Open or endless.

Plies : 2 to 7 Plies.

Cover Thickness : 0mm to 12 mm ,we could offer the conveyor belt have no top cover and upper cover.

Tensile Strength : 8 to 24 MPA.

Types of Synthetic Carcass : General Duty (GD), Extra Duty (ED) & Heavy Duty (HD).

Edges : Cut edges or molded.

Fabric : EP,NN,CC,TC.

Conveyor Belt Catalogue |

Rough top conveyor belt |

Steel cord conveyor belt |

Nylon Conveyor belt |

Polyester conveyor belt |

Polyester cotton conveyor belt |

Heat resistant conveyor belt |

High temperature resistant conveyor belt |

Common flame retardant conveyor belt |

Chemical resistant conveyor belt |

Oil Resistant conveyor belt |

Cold resistant conveyor belt |

Patterned conveyor belt |

Endless conveyor belt |

Foodstuff conveyor belt |

Whole-core flame retardant conveyor belt |

- Q: How do you identify the antistatic belt? Do you have any identification on it? Please give me an example

- Electrostatic, electronic industrial equipment, 0745 optical industrial machines, transmission couplings, transmission belts, and others shall be marked and readily recognizable, and shall not be associated with [Edit] paragraph how to withdraw the trademark registration application trademark

- Q: What are the five failure modes of gear wheel drive?

- The most important part of gear is the gear tooth. There are four main forms of its failure: tooth break, tooth surface wear, tooth surface pitting and scuffing of tooth surface1. broken teethBecause the stress on the tooth root is the greatest, and there is stress concentration, therefore, the fracture of the gear tooth usually occurs at the root of the toothIf the tooth unilateral work, root bending stress is tensile, the other side is compressed, the tooth is disengaged, the bending stress is zero. Therefore, in the repeated load, the bending stress exceeds the bending endurance limit, the root part will cause fatigue cracks. The crack gradually expand, will eventually cause the broken broken teeth, known as fatigue fracture.The sudden fracture of the gear due to short time overload or impact overload is called overload breaking. This kind of gear is easily broken by gears made of brittle materials such as hardened steel or cast iron

- Q: What are the types of commonly used drives? Try to describe their respective characteristics and Applications

- 3, the circular belt is a circular belt, which can be freely bent and driven. The belts are mostly made of polyurethane and usually have no core body, the structure is the most simple and the use is convenient. The circular belt has opened up a new way for belt transmission, and the amount of consumption in small machine tools, sewing machines, precision machines and other fields all over the world is increasing rapidly, and the potential is very great in the future.4, the toothed belt, also known as synchronous belt, is divided into single tooth belt and double-sided belt with two types. The former is mainly used in single shaft transmission, the latter is multi axle or reverse transmission. The toothed belt is divided into two kinds of trapezoid and arc shapes according to the shape of the tooth, and the torque is the largest with the synchronous belt of the circular tooth. Often used in synchronous transmission, low noise occasions

- Q: Do I need to add grease to the V belt or belt?

- No, the belt is part of the transmission that is designed to transmit power,

- Q: An object with a relatively 4m per second speed transmission belt, acceleration is 1m/s^2, the speed belt is 1m/s, and the motion in the opposite direction, now has a fixed point in the transmission A belt, A belt with mobile A, known distance of objects into the belt where the distance is 4m, for objects time to AIt's 4*T+0.5*1*t^2=4, but it really surprised me. Why is the speed 4? The relative speed of the belt is 3?But the teacher also said that this type of questions just to see, do not look at the transmission belt objects to relative 4 speed transmission belt, is calculated to 4? But always felt very contradictory? If so, then the people on the treadmill but practical and relatively static movement in motion

- The object and the drive belt is back to the line, the sports department is actually the muzzle velocity of uniformly accelerated motion, S = V + a - t / integrant.

- Q: What are the advantages and disadvantages of chain drive and synchronous belt pulley?

- Advantages: 1., constant transmission ratio;2. compact structure;3., because of the thin and light, high tensile strength, so belt speed up to 40 m/s, transmission ratio of 10, transmission power of up to 200 KW;4. high efficiency, up to 0.98.Characteristics and application of chain driveIt consists of chain wheel and ring chainFunction: the meshing between chain and sprocket teeth is driven by the same direction between parallel shafts.

- Q: What are the common knowledge of driving belts?

- Before removing the old belt, check the alignment of the drive wheel first. If the drive shaft is not parallel, or the drive wheel deviates from the axis, the drive will wear the belt and make it premature. The offset forces the belt to twist or twist during operation, thereby exerting uneven tension on the tension line. The transmission may fall off the wheel when the adjustment is not allowed to be the most severe. The correction is not allowed to be tested at right angles. If the gap between the surface of the drive wheel and the right angle occurs, it indicates that the axis is not parallel. Once the axis is not parallel, you must adjust or replace the missing drive wheel, wheel bracket or shaft

- Q: How to clean the belt of machining center?

- When the belt is in use, if it is stained with oil or grease, it will slip easily and cause damage to the belt.

- Q: What are the types of transmission belts?

- The positions of the two axes can be divided into planar gear drive and space gear drive.According to the type of gear drive:

- Q: What is the relationship between the elastic slip of belt drive and the effective tension at the initial tension of the belt?

- Elastic slide: belt drive at work, from the tight side to the loose side, the belt is subject to changes in tension, so the band of elastic deformation is also changing. In belt transmission, the relative motion between the belt and the pulley due to the elastic deformation of the belt is called elastic sliding. The elastic sliding results in the circumferential velocity V2 of the driven wheel, the circumference speed V1 of the driving wheel, and the degree of velocity reduction can be expressed by sliding rate epsilon.

Send your message to us

Rubber Conveyor Belt

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords