Gear planetary sun gear OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Material: | Steel,as requirements | Processing: | Forging | Pressure Angle: | 20 |

| Place of Origin: | Zhejiang China (Mainland) | technology of material: | forging | technology of machining: | hobbing,shaving,grinding |

| heatreatment: | nitriding,carburization | OEM: | is acceptable |

Packaging & Delivery

| Packaging Detail: | packed in carton |

| Delivery Detail: | 70days |

Specifications

1.produce as drawings

2.material will be as requirements

3.strictly quality control

4.OEM is acceptable

Products information:

1. suitable for many sorts of transmission system, such as agriculture tractor, wind power, truck and other industry zone.

2. material and precision can be as requirements.

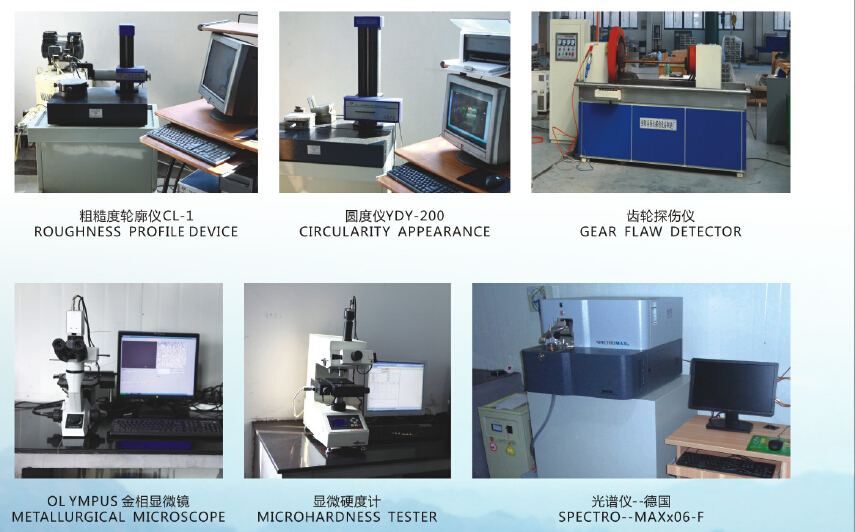

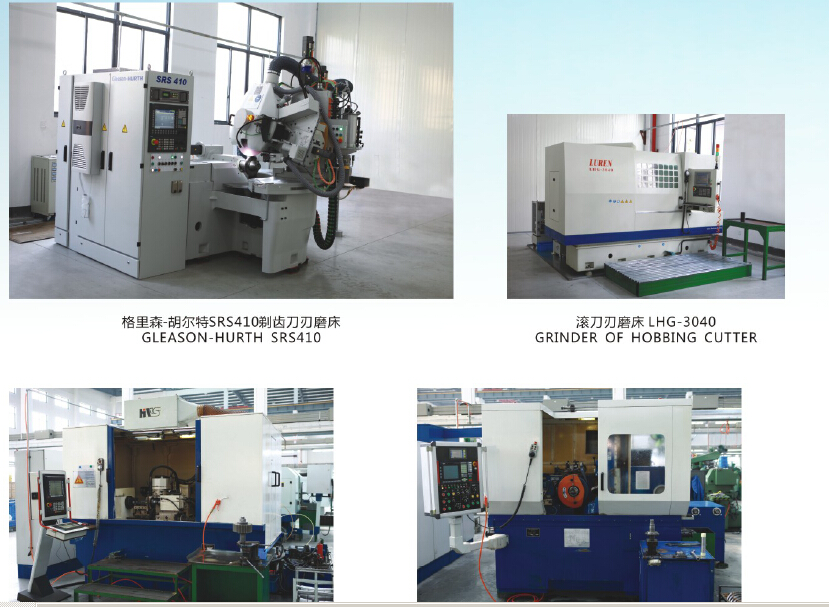

3. we have complete gear machining equipments: gear hobbing machine, shaving machine, gear shaper, gear grinding machine, and our own heat treatment center. all of the production procedure are strictly controlled by ourselves, no cooperation procession, so we can sure the final products to meet your requirements.

4.each processing, strictly quality control

5.certificate: ISO9001, ISO/TS16949

- Q: Where does the hydraulic oil of the slewing ring of excavator ring out?

- The reason for this phenomenon is sheathed on the rotary vertical shaft seal damage (figure is marked with the red part), caused by oil hydraulic motor and reducer into rotary butter dish, and then from the back gear position of the hydraulic oil leakageIt is very good to know the principle of the motor. The position of the rotary motor and the reducer is hydraulic, while the lower gear and the gear ring are lubricated by butter

- Q: Parameters of flywheel ring gear for single cylinder diesel engine

- What type can be used to determine the parameters of the flywheel ring gear, the number of teeth of the starter motor gear and the structural dimensions of the starting motor mounting bracket.

- Q: The number of teeth in my inner ring gear is 80, the modulus is 6, the addendum factor is 0.8, and the root coefficient is 0.25

- Ha ha, that is the plug-in to download, hang up, will not contact me, 15 quick guarantee you can use

- Q: In the processing of gear ring down end angle is cumbersome, requires a lot of hard work, Master Wang, senior, Ariadne, how fast, mass production? What kind of chamfer do you use? What knife do you use? We take out sun drying, learn from each other, study together, improve efficiency ~ ~ ~!

- The quality of the products with excellent machining, cutter bar, blade is Changchun Hriday, life is not good, there is now imported from Germany can be installed double blade knife rod (knife rod has differential cylinder adjustable, precision, higher strength, but the price is high, about 10 thousand yuan), Germany, Japan also has a blade Sumitomo so, for reference.

- Q: The role of automobile gear ring

- Hello, dear! Adjacent stall conversion, we should take different steps of the same principle applies to mobile gear shift, the question is the former joint engagement ring gear and sets the rotational speed requirements, and the latter to engage a gear meshing point line speed requirements, but the speed of analysis is based on the principle of the same.

- Q: How to remove the flywheel ring gear of the van engine?

- Assemble new gear ring: clean the flywheel ring and blow dry first. The ring gear with waste oil is heated to 30035090, so that the inner diameter swell, while hot pressing to rapid vertical flywheel or with a hydraulic machine on the outer edge, and check whether the assembly in place, fit, natural, after cooling has a certain degree of tension. In order to prevent the gear ring from loosening, it can be drilled at every 1200 places and fixed by the steel pin method.After the gear ring is assembled firmly, the chamfering of the gear still needs to be repaired.

- Q: Can the parameters of the starter gear be deduced according to the parameters of the flywheel ring gear of the engine?

- The diameter of the addendum circle, the diameter of the tooth root circle, the coefficient of deflection, the length of the normal line and the thickness of the tooth also need to be measured from the center of the flywheel gear ring to the starter gear.

- Q: About diesel electromechanical starter flywheel gear ring and flywheel

- When the gear ring is cooled, the gear ring fits firmly with the flywheel. It seems that the quenching of the gear ring is also in progress at the same time. Hope to be of help to you.

- Q: PROE simulation, how to make the inner ring does not move, the planet wheel around the rotation

- After entering the mechanism, the initial relative position of the planetary gear and the inner gear ring is set up, which is matched with the groove of the right gear, and then the gear connection is added, the transmission ratio is set up, and the motor is added, and the mechanism is analyzed and operated

- Q: How many teeth ring for 11 teeth starter?

- 1, 11 teeth starter with 110 teeth or so gear ring.2, because the starter gear and engine flywheel gear ring transmission ratio is generally about 1 to 10, so the 11 teeth starter with 110 teeth or so gear ring.3, gear ring meaning: flywheel gear ring is heated after inserted on the outer edge of the flywheel, cooled after fastening on the outer edge of the flywheel, used to engage with the starter gear, drive crankshaft rotation, start the engine.

Send your message to us

Gear planetary sun gear OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords