Spline shaft OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Material: | Steel,as requirements | Processing: | Forging | Pressure Angle: | 20 |

| Place of Origin: | Zhejiang China (Mainland) | technology of material: | forging | technology of machining: | hobbing,shaving,grinding |

| heatreatment: | nitriding,carburization | OEM: | is acceptable |

Packaging & Delivery

| Packaging Detail: | packed in carton |

| Delivery Detail: | 70days |

Specifications

1.produce as drawings

2.material will be as requirements

3.strictly quality control

4.OEM is acceptable

Products information:

1. suitable for many sorts of transmission system, such as agriculture tractor, wind power, truck and other industry zone.

2. material and precision can be as requirements.

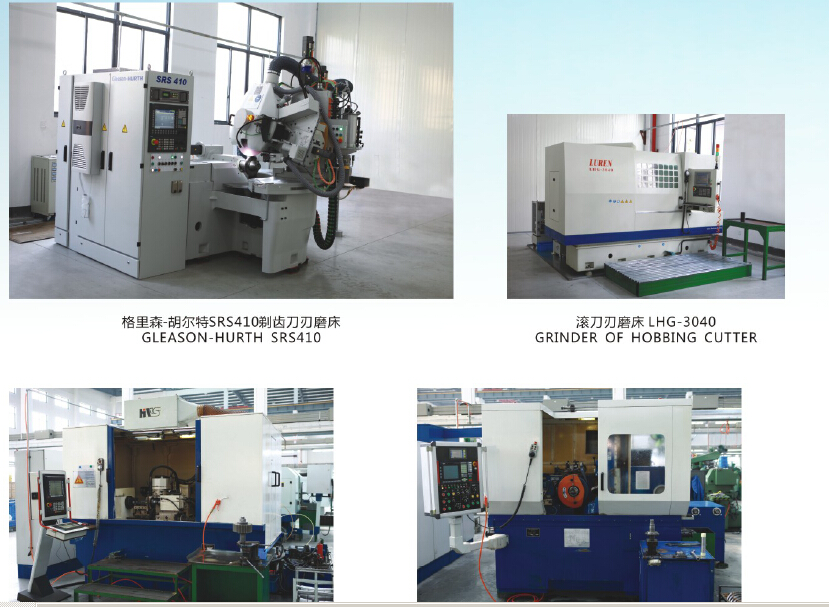

3. we have complete gear machining equipments: gear hobbing machine, shaving machine, gear shaper, gear grinding machine, and our own heat treatment center. all of the production procedure are strictly controlled by ourselves, no cooperation procession, so we can sure the final products to meet your requirements.

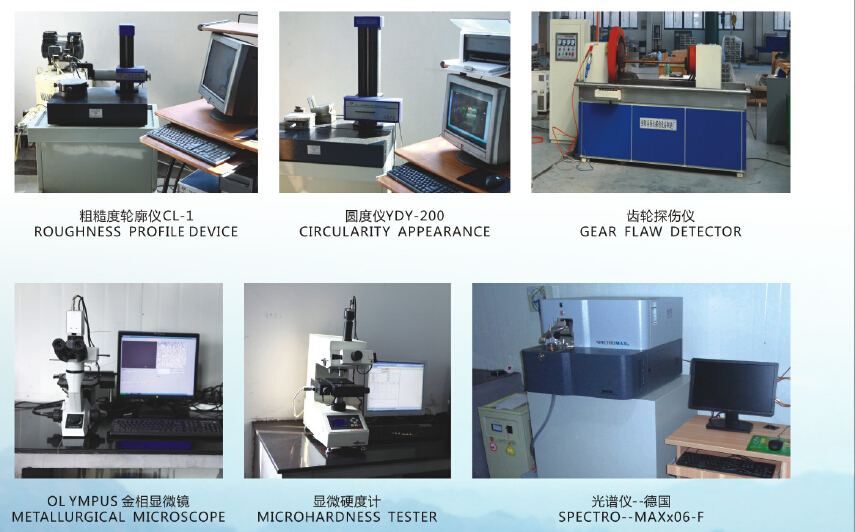

4.each processing, strictly quality control

5.certificate: ISO9001, ISO/TS16949

- Q: Flywheel ring gear with 167 teeth with several teeth motor

- As the provisions of the diesel engine has a specified number of the diesel engine gear, such as 6105QC -110 6110-141 Wuxi Yuchai gear tooth

- Q: In synchronous transmission, often combine the ring gear and the normally meshed helical gear made of two bodies (two connected by a spline), this is why? With the ring gear by the torque constant meshed helical gear to pass combining sets, but the combination of gear tooth width and tooth width. Normally meshed helical gear is bigger, this is what reason?

- In the synchronizer gearbox, often combine the ring gear and the normally meshed helical gear made of two bodies (two connected by a spline), this is why? because in gear machining, gear hobbing efficiency is relatively high (compared with the gear, and combined with the existing gear) ""

- Q: Are the driven teeth and gear ring of the gearbox integrated? Very main

- The gear shift ring with small teeth difference is fixed on the case without movement, and the utility model has the advantages of large change speed. Planetary gear shift motion,

- Q: In the processing of gear ring down end angle is cumbersome, requires a lot of hard work, Master Wang, senior, Ariadne, how fast, mass production? What kind of chamfer do you use? What knife do you use? We take out sun drying, learn from each other, study together, improve efficiency ~ ~ ~!

- The quality of the products with excellent machining, cutter bar, blade is Changchun Hriday, life is not good, there is now imported from Germany can be installed double blade knife rod (knife rod has differential cylinder adjustable, precision, higher strength, but the price is high, about 10 thousand yuan), Germany, Japan also has a blade Sumitomo so, for reference.

- Q: How many teeth of the 12 gear starter is suitable for the gear ring?

- Your question has a problem, the 1332d1315c138c 12 starter gear, and the ring gear with a lot of them, 140.141 and 1951115 plus single cylinder gear, generally used in a single cylinder diesel engine, according to your installation position selection.

- Q: The role of automobile gear ring

- Gear shifting of transmission, especially shift from high-grade to low gear, is more complicated, and it is easy to produce impact between gear teeth or spline teeth. In order to simplify the operation and avoid the impact between the teeth, a synchronizer can be set in the gear shift device. An inertial synchronizer is synchronized by friction, and a special mechanism is arranged on it to ensure that the engagement ring and the spline gear ring to be joined can not be contacted before the synchronization is achieved, thus avoiding the impact between teeth. Hope to help you, please also set the best answer! Thank you

- Q: In a synchronizer of a transmission, why do the engagement ring and the normally engaged helical gear be made into two bodies?

- The synchronizer of the synchronizer is divided into several structures, and different structural designs are designed for its functions

- Q: Ring gear material 50Mn heat treatment, conditioning is shrink or rise?

- It also has something to do with the shape and size of the parts. It's better to do experiments.

- Q: What's the relationship between the number of teeth on the flywheel ring of the engine and the election? I know that it is engaged with the starter. Is it possible to choose a small starter to start fast? How can I choose this?

- This can not be arbitrarily selected, choose a few teeth seriously affect the motor use, may be burned, as stipulated in the diesel engine has a specified number of the diesel engine gear, such as Yulin 6105QC is -110 gear

- Q: Processing technology of external gear ring for help

- General process: 1. cars: rough car parts, leaving 2. cars: fine car parts, both sides of the mill to stay, Kong Liumo quantity 3. grinding: grinding two end (or leave the fine grinding amount)

Send your message to us

Spline shaft OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords