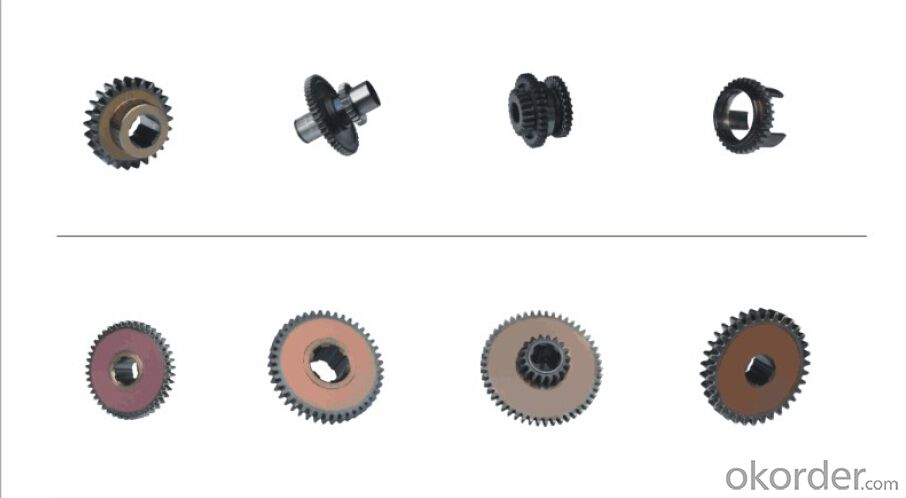

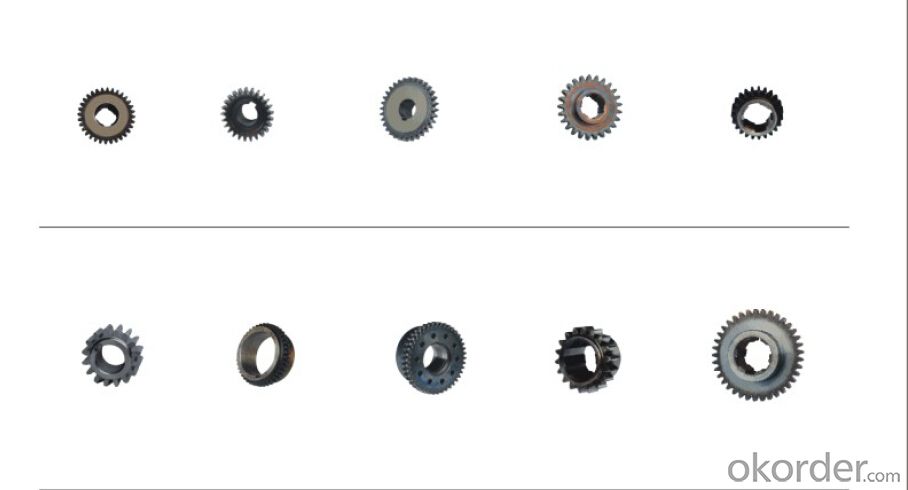

Gear planetary gear OEM hobbing,shaving,grinding for machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Material: | Steel,as requirements | Processing: | Forging | Pressure Angle: | 20 |

| Place of Origin: | Zhejiang China (Mainland) | technology of material: | forging | technology of machining: | hobbing,shaving,grinding |

| heatreatment: | nitriding,carburization | OEM: | is acceptable |

Packaging & Delivery

| Packaging Detail: | packed in carton |

| Delivery Detail: | 70days |

Specifications

1.produce as drawings

2.material will be as requirements

3.strictly quality control

4.OEM is acceptable

Products information:

1. suitable for many sorts of transmission system, such as agriculture tractor, wind power, truck and other industry zone.

2. material and precision can be as requirements.

3. we have complete gear machining equipments: gear hobbing machine, shaving machine, gear shaper, gear grinding machine, and our own heat treatment center. all of the production procedure are strictly controlled by ourselves, no cooperation procession, so we can sure the final products to meet your requirements.

4.each processing, strictly quality control

5.certificate: ISO9001, ISO/TS16949

- Q: 1115 how many teeth are used when the diesel engine is switched on?

- If there are any problems in the above, please fix or replace it.

- Q: What gear can be used to evaluate the radial runout of ring gear?

- In actual measurement, the proper measuring method should be chosen according to the actual situation and equipment, but the final aim is to minimize the radial runout error of the gear ring

- Q: How is the flywheel connected to the ring?

- Storage of part of the energy in the engine's work stroke to overcome the resistance of other strokes and rotate the crankshaft evenly.

- Q: What is the difference between the mechanism of fine blanking and the mechanism of conventional blanking?

- A V - shaped rib around a certain distance from the workpiece contour. The action of the ring clamp is to prevent the metal sheet other than the shear zone and into the shear zone during the blanking

- Q: Are the driven teeth and gear ring of the gearbox integrated? Very main

- The gear shift ring with small teeth difference is fixed on the case without movement, and the utility model has the advantages of large change speed. Planetary gear shift motion,

- Q: The radial runout of the gear ring affects the accuracy of the gear drive, so the gear is to be checked on the shaft and the runout of the end face.

- Therefore, after the gear is mounted on the shaft, check (A radial runout) and runout of the end face

- Q: Such as the title, consult an expert with us auto parts "flywheel and gear ring assembly" pressing method. At present there is no mature cold pressing process???Yes, press assembly, gear ring to match with the flywheel, not the gear ring fault analysis!? is there a cold pressing?

- The common damage forms of engine crankshaft include shaft neck wear, crack, burn, bend or break.Inspection methods are given, such as repair dimension method, surfacing welding, arc spraying, brush plating and manual arc welding. The cause of the starter and the flywheel gear meshing. The ring gear and the starter gear will strike when starting the engine, causing tooth damage or side wear of the tooth. If the tooth is damaged or worn more than three times, the starter gear is difficult to mesh with the ring teeth...

- Q: The number of planet gear is 20, the drive ratio is 7.5. The number of teeth of solar wheel and ring gear is required

- That is in direct contact with the center of the planetary gear wheel or tied as the driving link drives a planetary gear, a planetary wheel around its axis of rotation O1-O1, on the other hand, with the development of component H (or tied) around a fixed axis (O-O axis rotary wheel center)

- Q: What's wrong with the gear ring slip?

- 1, driven by a motor starter gear to drive the flywheel, a clutch, suction and pull switch, belonging to the slip engaging device is broken, fight tooth squeaking and spark is pulling switch and drive gear or flywheel ring gear is bad of course for many reasons, the spark plug for oil, electric fuel supply, fuel supply system no, low temperature, low pressure etc..

- Q: Is the flywheel ring prone to failure?

- IntroductionSince 2006 I stand the vehicle equipment replacement of flywheel ring gear 14 which Shandong F11361 bus replacement of 4 passenger car 2, the replacement of the 2 passenger car No. 1, No. 3, No. 4 and No. 1 forklift loader No. 8 the replacement of 1 loader No. 2 replacement of 2. The reasons for the change are due to abnormal sound at starting time. After disassembling the starter, it is found that the gear ring of the flywheel is basically milled along the three ring teeth of the circumferential gear ring, and some of the starter one-way clutch gears are worn out. Through the inspection and analysis and summarizes the causes of flywheel ring gear tooth milling reason has the following six aspects such as tree shown wear fault pre engagement end clearance operation maintenance assembly parts quality dynamic balance of flywheel fork 1, 2, 3, 4, one-way clutch sleeve spline 1, the time interval of 2, 3, check the battery frequently start 4, two, 2, 1 forced to start spring gap 3, 1, 2, the quality gap is small, the purchase of 1, producing 3, 3, 2 heating assembly installation direction 1, 2 fixed point and uneven wear failure analysis flywheel gear milling for different faults out regular inspection and maintenance to strengthen operation training and check the standard 3-5mm adjusted 3mm along the circumference uniformly heated to 150 DEG C to 200 DEG C to observe the distribution of the flywheel mark buyer and technicians strictly

Send your message to us

Gear planetary gear OEM hobbing,shaving,grinding for machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords