Gear planetary gear CNH OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Material: | Steel,as requirements | Processing: | Forging | Pressure Angle: | 20 |

| Place of Origin: | Zhejiang China (Mainland) | technology of material: | forging | technology of machining: | hobbing,shaving,grinding |

| heatreatment: | nitriding,carburization | OEM: | is acceptable |

Packaging & Delivery

| Packaging Detail: | packed in carton |

| Delivery Detail: | 70days |

Specifications

1.produce as drawings

2.material will be as requirements

3.strictly quality control

4.OEM is acceptable

Products information:

1. suitable for many sorts of transmission system, such as agriculture tractor, wind power, truck and other industry zone.

2. material and precision can be as requirements.

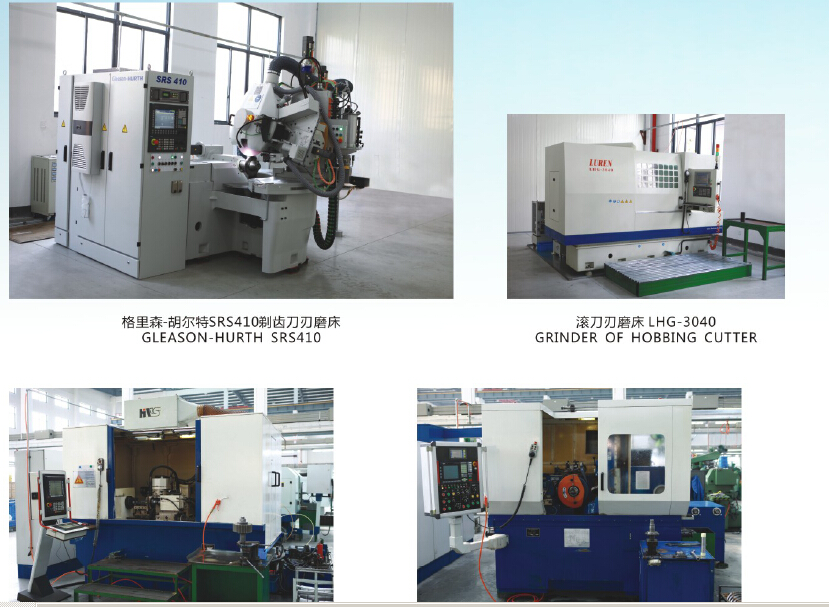

3. we have complete gear machining equipments: gear hobbing machine, shaving machine, gear shaper, gear grinding machine, and our own heat treatment center. all of the production procedure are strictly controlled by ourselves, no cooperation procession, so we can sure the final products to meet your requirements.

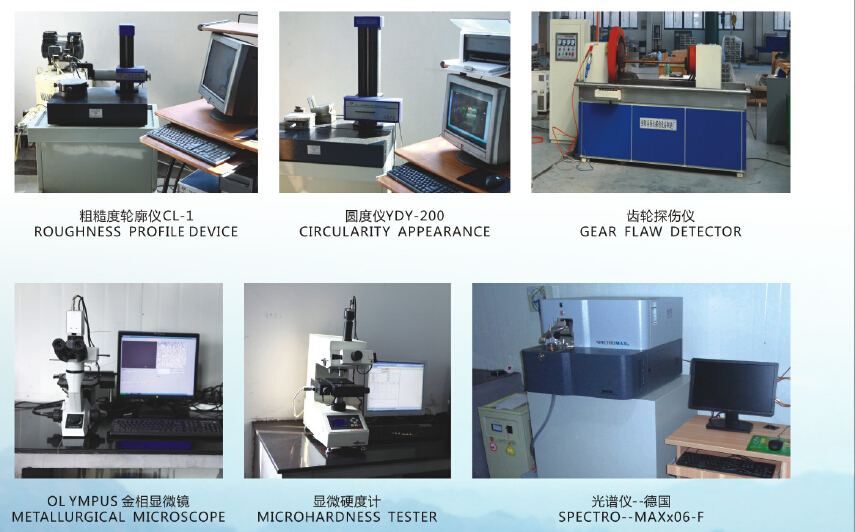

4.each processing, strictly quality control

5.certificate: ISO9001, ISO/TS16949

- Q: For planetary gears, the fixed ring gear connects the sun wheel and the planet carrier, but does it still move?

- Before and after the two planetary sun gear is connected into a whole, called the sun before and after the wheel assembly (2) in front of a ring gear planetary frame of the planetary row and a planetary connection to another one, called the former planet and ring gear assembly

- Q: How is the flywheel connected to the ring?

- Storage of part of the energy in the engine's work stroke to overcome the resistance of other strokes and rotate the crankshaft evenly.

- Q: Parameters of flywheel ring gear for single cylinder diesel engine

- Single cylinder diesel electric starter type there are a lot of different diameter or different manufacturers of flywheel gear parameters are not necessarily the same

- Q: How to deal with the bite gear of starter drive gear and flywheel ring gear?

- Suggest replacing gears!2, the starter gear and flywheel teeth are loose, gear fixed position due to force displacement, resulting in tooth biting!It is recommended to be tested and fixed in detail!

- Q: The role of automobile gear ring

- Hello, dear! Adjacent stall conversion, we should take different steps of the same principle applies to mobile gear shift, the question is the former joint engagement ring gear and sets the rotational speed requirements, and the latter to engage a gear meshing point line speed requirements, but the speed of analysis is based on the principle of the same.

- Q: About diesel electromechanical starter flywheel gear ring and flywheel

- I'm not sure about the single cylinder. I think it should be the same as a multi cylinder engine. The gear ring and the flywheel are interference fit, and the exact tolerances need to be further investigated.

- Q: How many teeth ring for 11 teeth starter?

- The transmission ratio between the starter gear and the flywheel ring gear of the engine is generally about 1 to 10, and the 11 teeth starter uses 110 teeth or so.

- Q: The starting mode of a vehicle engine, in addition to the engagement of the cranking ring of the starter motor and flywheel, causes the crankshaft to start, what other starting methods are there? More details, thank you

- 2) the starting and starting device of the auxiliary gasoline engine is large in volume and complex in structure, so it is only used for the starting of large power diesel engines.

- Q: Is the flywheel ring prone to failure?

- 2, when the starter rotor shaft copper sleeve wear, easy to cause the rotor shaft rotation is not concentric, at this time, if not check to aggravate copper sleeve wear, one-way clutch gear eccentric, the top teeth cause the flywheel gear ring wear.3, when the rotor keyway on corrosion or accumulation of sludge, will cause one-way clutch mechanical propulsion strength weakened, resulting in lower speed. So when the starter drive gear of the one-way clutch and flywheel ring gear meshing and not switch contacts at the other end of the core in the drive circuit is connected to the main switch starter motor rotor rotation began to appear strong "Tsatsa" sound caused by milling. The solution to avoid milling first should pay attention to regular inspection and maintenance of starter fork and accessories wear inspection of the copper sleeve wear and lubrication check buffer spring pressure and spline cleaning and lubrication condition to ensure the advancing speed of the one-way clutch. When maintenance, in the spline parts can not be filled with butter, if necessary, less oil, you can wear copper, you need to change in time, plus MP3, lithium based grease lubrication.

- Q: Processing technology of external gear ring for help

- 4. Grinding: grinding (or grinding the amount of fine grinding) 5. rolls: tooth products (if it is 7 level precision) 6. pliers: deburring 7. heat: tooth high frequency

Send your message to us

Gear planetary gear CNH OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords