Parts For Crushing Plant

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 Sets set

- Supply Capability:

- 1000 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Parts for Crushing Plant:

Used for mining and construction part

Material: carbon steel

Process: silicon sol process

Processing method: investment casting, CNC machining and assembling

Packaging: standard export packaging (plastic bag and carton) or according customer's request

High quality and reasonable price

Usage of Parts for Crushing Plant:

jaw plate for crusher is easy to install, operate and maintain. As per feedback, our experts will make continuous improvements on our products to meet customers' changing needs. Every feature of Zenith jaw plate for crusher has been carefully designed to provide superior quality and performance. It is widely used in fields of mining, metallurgy, construction, smelting, hydropower and chemical industries etc. Zentih has competive jaw plate for crusher price for you.During operation, the motor drives the eccentric shaft shells to turn around through a horizontal axle and a pair of bevel gear. The axle of crushing cone swings with the force of eccentric shaft shell so that the surface of the crusing wall is close to the roll mortar wall from time to time. In this way, the ores and rocks will be pressed and crooked and crushed.

1) Material: high manganese steel: Mn13%, Mn18%, Mn24% High chromium iron: Cr20, Cr24 up Carbon Steel HT200 QT400-15

2) Use: Machinery in metal recovery smash, mine, metallurgy, chemical industry, cement, petroleum etc.

3) Production quality testing: High frequency infrared carbon & sulfur analyzer, Metallographic microscope, Machinery performance testing equipment, Hardness testing equipment, Ultrasonic inspection equipment

4) Easy installation: The anti-abrasion block is a semi-permanent part, which is easy for replacement.

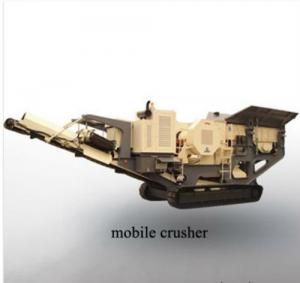

Picture of Parts for Crushing Plant:

- Q: What is the principle of the shock absorption system of a vibrating screen?

- Working principleThis type of sieving machine adopts double vibration motor self synchronization technology. The two vibrating motors are respectively arranged at the top of the screen machine to rotate at opposite high speed, and the eccentric centrifugal force generated by the eccentric block of the rotating box causes the sieve box to produce a certain amplitude of linear movement. Because of the vibration sieve surface and the level of 10 degree angle installation, vibration line and the horizontal plane is 45 degrees, the screen material is passed to the sieve box and impulse continuous casting movement and the material is layered in advance, throw up, make less than sieve particles and slurry water through the sieve in and the screen met in the process of completing the screening process.

- Q: What is the structure principle of sweet potato starch vibrating screen?

- The vertical vibration motor as vibration source, and the motor is installed at both ends of the eccentric weights, the rotary motion of the motor into a horizontal, vertical, inclined three sport, then this movement is transferred to the screen surface for screening.

- Q: What are the common faults of vibrating screen? How to eliminate the trouble of vibrating screen?

- In normal operation, the rotation of the sieve machine slows down and the bearing is heatedFailure cause:1) the bearings lack lubrication oil2) bearing block3) excessive oil in the bearings or improper oil added4) bearing damage or poor installation, eccentric block on the round off, eccentricTroubleshooting:1) inject lubricating oil into the bearings2) clean the bearing, replace the sealing ring, and check the labyrinth sealing device3) check the lubrication of the bearing4) replace the bearing, install the eccentric block, adjust the round wheel

- Q: OK, where can I get the shaker dust collector?

- The device consists of dust catcher, fan, pLc automatic pulse blowing system, hanger, inspection door, sealing soft curtain and so on. The use of vibrating screen dust collector can avoid the dust flying everywhere and pollute the environment, and contribute a lot to the protection of the earth environment. With the increase of the surface of the filter bag dust, knife resistance value reaches a predetermined value, the pressure sensor to the electronic control box indicating signal, by pLc automatic control system for automatic pulse jet bag was blowing, attached to the bag on the dust shake off, after unloading ash pipe directly to the sealing belt. That is to keep the filter bag good filter performance, and no two dust.

- Q: Vibration motor and vibration sieve, why use C3 or C4 clearance bearings and use?

- Because the greater the clearance of the bearing, the lubrication of the vibrating screen can be guaranteed, the general vibration screen bearing room wearing parts, large clearance can also increase the bearing life.

- Q: How much is the amount of the vibrating screen to be calculated?

- Vibration motor grade can be divided into: six, four, two, and its shape can be divided into horizontal vibration motor and vertical vibration motor. When we choose, we should select the motor vibration times N (r/min) and double amplitude S (mm) according to the requirements of production and the type of screen machine.

- Q: How does the mine vibration sieve do not do?

- The gangue can be rolled several times or rolled for a longer time and can be screened. In addition, the amount of screening is reduced and the slag can be fully shaken and screened on a vibrating screen

- Q: Domestic ultrasonic vibration sieve power supply transducer, which is better?

- Are almost the same, not to do any good, because the work principle, there is to see which in the selection of electronic fittings, ceramic pellet, materials and so on is good things, responsible attitude and workers in the installation work. At present, there is no home to do is unique, more distinctive, or stability is better

- Q: Can the linear vibrating screen not be horizontally placed? How big is the dip angle?

- But in accordance with the requirements of individual process and some special needs, the linear vibrating screen can also be placed with a certain angle, usually 5 degrees or 10 degrees. Because the linear vibrating screen is mainly used for classification of fine materials and dehydration, desliming, etc., so if the angle is too large, it may lead to poor screening efficiency.

- Q: What is the required opening rate of the vibrating screen?

- You mean screen or something?. In fact, each kind of vibrating screen is different, each has its advantages and disadvantages. You can search Xinxiang for major materials introduction.

Send your message to us

Parts For Crushing Plant

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 Sets set

- Supply Capability:

- 1000 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords