Food Grade PVC Conveyor Belt PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Food Grade PVC Conveyor Belt PU Conveyor Belt

Food Grade Conveyor Belt

Food Grade Conveyor Belt Introduction

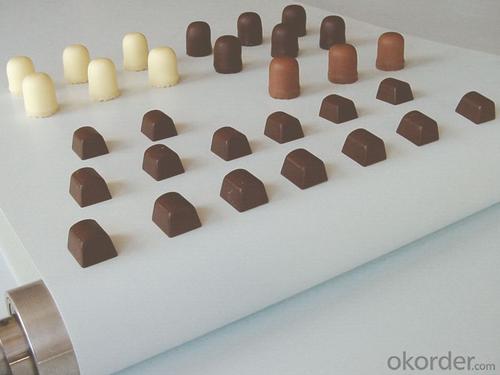

Food processing conveyor belt choose high quality high strength polyester fabric are the core, coated with PU or PVC as loading surface. With advantages of good flexibility, material environmental friendly, light duty, high tensile strength, anti oil, easy learning, our food processing conveyor belt meet EU and USA market requirements.

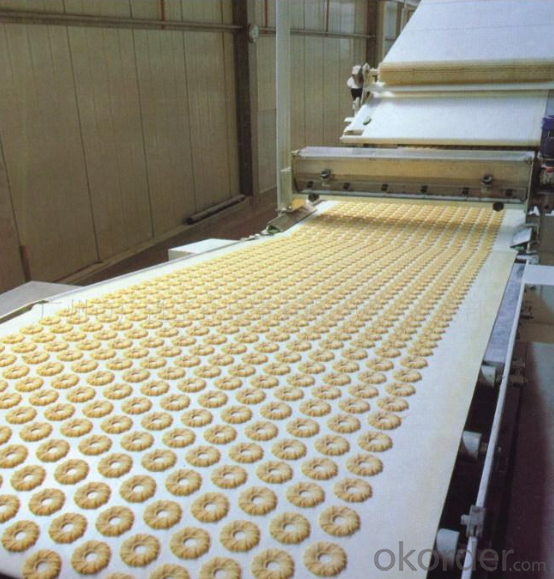

Food Grade Conveyor Belt Application

Food processing conveyor belt is widely used in food industry, such as vegetables, snack food, beer, sea food, etc.

Food Grade Conveyor Belt Advantage

Food processing conveyor belt is made of harmless material, no toxicity, no smell, anti-oil, easy cleaning, high tensile strength, good flexibility, light weight, solid and durable.

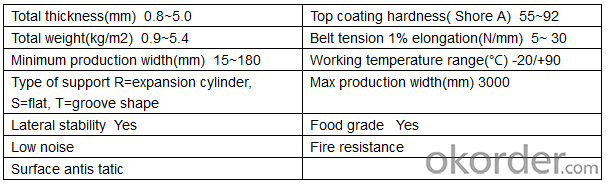

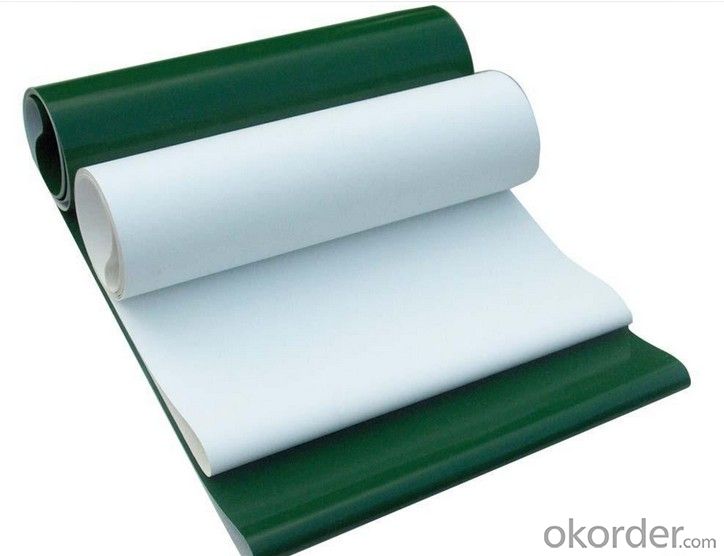

Food Grade Conveyor Belt Specifications

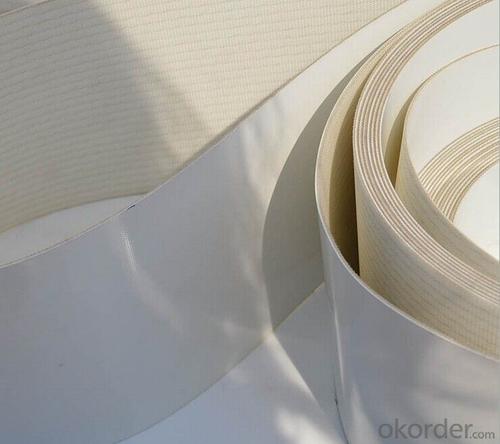

Thickness: PVC Belting (1~7mm) PU Belting (0.8~4mm)

Width: 200mm ~ 4000mm

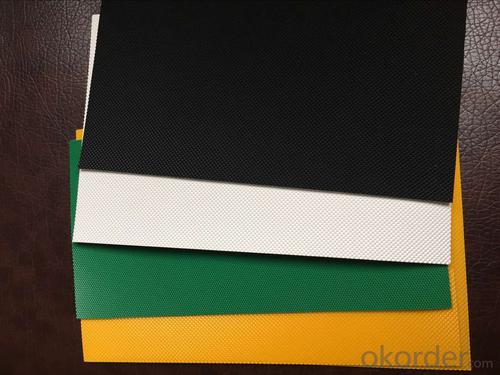

Appearance: Flat surface, diamond pattern, lawn pattern, golf pattern,etc.

Colors: Green, blue, gray, white, black, blue, dark green, transparent,etc.

Subsequent machining technology: It can add baffle, skirt, sponge, guide bar,etc.

Food Grade Conveyor Belt Photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2.How can I get some samples?

A: We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

B, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

3. How about your quality?

Quality is the first priority, we have strict quality control system.

1) All raw material we used are environmental freindly

2) Quality Control Department specially responsible for quality checking in each process. We make testing on incoming raw material and finished products. Your third party testing is also welcomed.

3) Skillful workers care every details in handling the producing and packing processes.

Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: Can olive nets be used for olive tree erosion control?

- Yes, olive nets can be used for olive tree erosion control. These nets are commonly used to protect the soil around olive trees from erosion caused by heavy rainfall or wind. They help in retaining the soil and preventing the loss of topsoil, which is crucial for the health and stability of the olive trees. Olive nets also assist in reducing surface runoff and promoting water infiltration, which further aids in erosion control.

- Q: Are olive nets resistant to hail or heavy rain?

- Yes, olive nets are typically resistant to hail and heavy rain. They are designed to protect the olive trees and harvest from external factors such as extreme weather conditions.

- Q: How are olive nets removed after harvesting?

- Olive nets are typically removed after harvesting by carefully pulling them down from the trees and collecting any olives that may have remained trapped in the net.

- Q: Can olive nets be used in combination with cover cropping methods?

- Yes, olive nets can be used in combination with cover cropping methods. Cover cropping involves growing a variety of plants to protect and enrich the soil, while olive nets are used to catch falling olives during harvest. By implementing cover crops in between olive tree rows, the nets can still be used effectively without interfering with the growth and benefits of cover crops. This combined approach can enhance soil health, prevent erosion, and improve overall olive tree productivity.

- Q: What are the processing methods of black masterbatch and what is more prominent than other plastic raw materials?

- In the dyeing of plastic products, black masterbatch only 0.6%-0.8%, it will be extremely black, and no more will not be more dark. According to the experimental data show that the product in Xinjiang area for outdoor use, such as the need to rely on black masterbatch anti aging, as long as the use of high-quality black masterbatch (rather than return material as carrier, oil wetting, dispersion of calcium carbonate and so on it), content of carbon black in the products reached 2-2.5%, namely: every 100 kilograms of raw materials, there is a 5-6 (the weight of 40%) containing carbon black masterbatch, the role played by far more than any anti aging products, product life can reach more than 10 years. That's why drip irrigation products, water delivery products, communications cable products are all black.

- Q: Are there any specific techniques for spreading olive nets over large areas?

- Yes, there are specific techniques for spreading olive nets over large areas. One common technique is using mechanical devices, such as net-laying machines, which can efficiently and evenly distribute the nets. These machines are often attached to tractors and can cover large areas quickly. Another technique involves using a team of workers to manually spread the nets by hand, particularly in areas with difficult terrain or uneven ground. Both methods require careful coordination and expertise to ensure the nets are properly and uniformly spread to protect the olive trees and facilitate harvesting.

- Q: Advantages and disadvantages of plastics

- The density of plastic is between 0.8-2.2g/cm3, generally only steel 1/3-1/4, aluminum 1/2, concrete 1/3, similar to wood. It can reduce the construction intensity and reduce the weight of the building.

- Q: What glue does the plastic product stick with?

- 502 glue for porous absorbent material and then, for iron and steel, nonferrous metals, rubber, leather, plastics, ceramics, wood, non-ferrous metals, non metals ceramics, glass and flexible materials such as rubber, leather, soft and hard plastic or their mutual adhesion, but of polyethylene, polypropylene, Teflon ethylene and other hard bonding materials, the surface through special treatment, in order to bond. Widely used in electrical appliances, meters, machinery, electronics, light instruments, medical, light industry, civil and so on.

- Q: How do olive nets prevent damage from heavy machinery during harvesting?

- Olive nets prevent damage from heavy machinery during harvesting by creating a protective barrier between the machinery and the ground. The nets are spread out beneath the olive trees, catching the falling olives and preventing them from hitting the ground directly. This helps to reduce impact and potential damage caused by the machinery's weight or movement, ensuring a safer and more efficient harvesting process.

- Q: Can olive nets be used to reduce the risk of soil erosion in areas with high rainfall?

- Yes, olive nets can be used to reduce the risk of soil erosion in areas with high rainfall. Olive nets are designed to cover the soil surface and prevent rainwater from directly hitting the ground, thus reducing the impact of heavy rainfall on soil erosion. Additionally, olive nets help to retain moisture in the soil and promote the growth of vegetation, which further helps in preventing erosion.

Send your message to us

Food Grade PVC Conveyor Belt PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords