PVC Conveyor Belt PU Conveyor Belt Food Processing Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Conveyor Belt PU Conveyor Belt Food Processing Industry

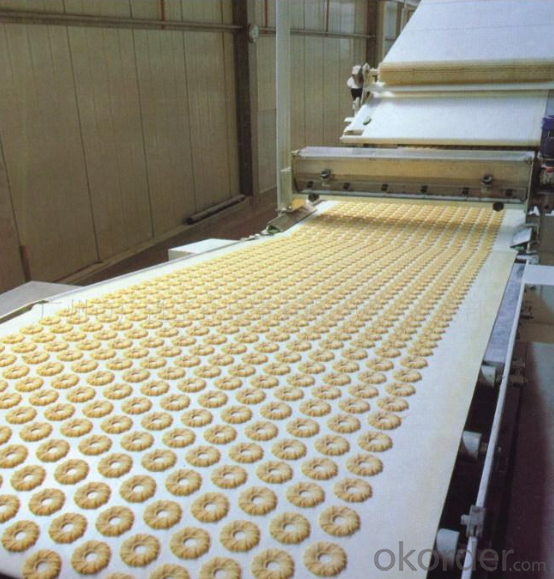

Food Processing Conveyor Belt

Food Processing Conveyor Belt Introduction

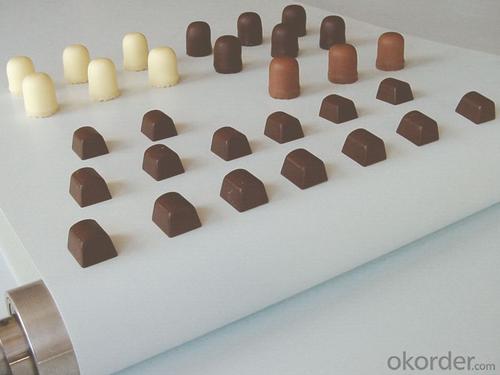

Food processing conveyor belt choose high quality high strength polyester fabric are the core, coated with PU or PVC as loading surface. With advantages of good flexibility, material environmental friendly, light duty, high tensile strength, anti oil, easy learning, our food processing conveyor belt meet EU and USA market requirements.

Food Processing Conveyor Belt Application

Food processing conveyor belt is widely used in food industry, such as vegetables, snack food, beer, sea food, etc.

Food Processing Conveyor Belt Advantage

Food processing conveyor belt is made of harmless material, no toxicity, no smell, anti-oil, easy cleaning, high tensile strength, good flexibility, light weight, solid and durable.

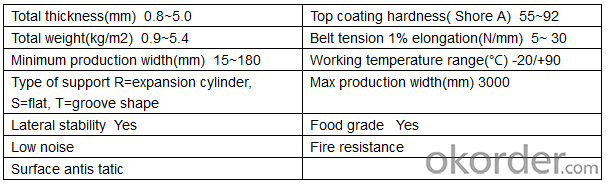

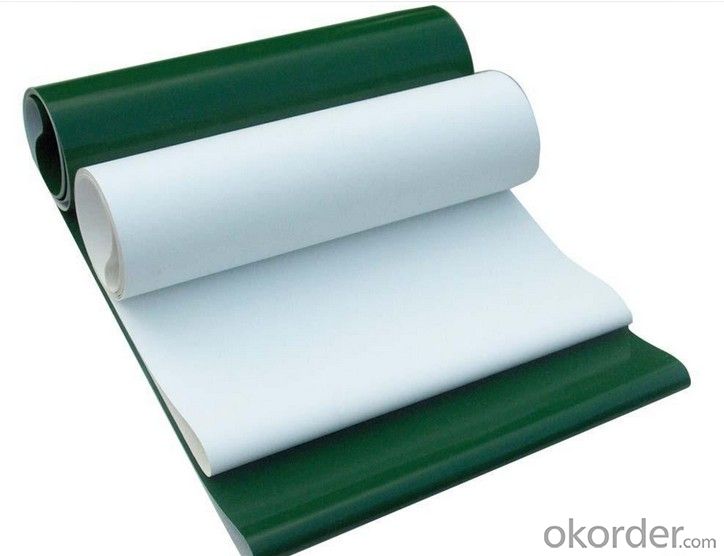

Food Processing Conveyor Belt Specifications

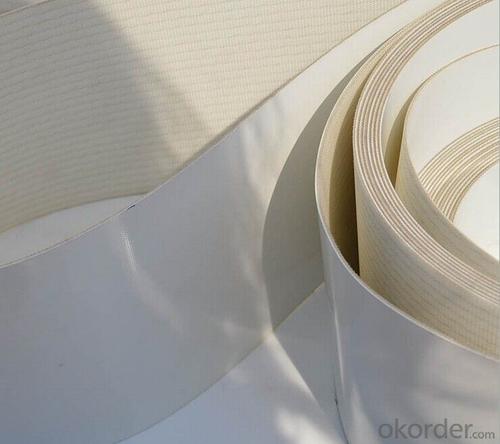

Thickness: PVC Belting (1~7mm) PU Belting (0.8~4mm)

Width: 200mm ~ 4000mm

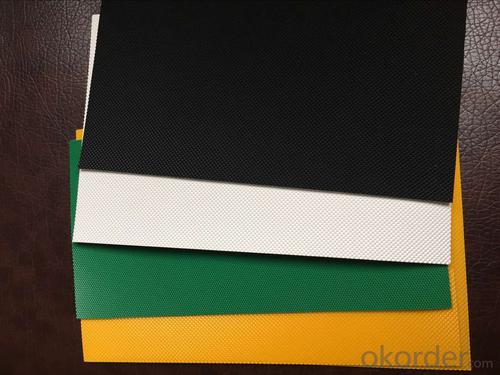

Appearance: Flat surface, diamond pattern, lawn pattern, golf pattern,etc.

Colors: Green, blue, gray, white, black, blue, dark green, transparent,etc.

Subsequent machining technology: It can add baffle, skirt, sponge, guide bar,etc.

Food Processing Conveyor Belt Photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

Quality is the first priority, we have strict quality control system.

1) All raw material we used are environmental freindly

2) Quality Control Department specially responsible for quality checking in each process. We make testing on incoming raw material and finished products. Your third party testing is also welcomed.

3) Skillful workers care every details in handling the producing and packing processes.

Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: How long do olive nets last?

- The lifespan of olive nets can vary depending on factors such as the quality of the net, frequency of use, and maintenance. However, on average, olive nets can last anywhere from 3 to 5 years if properly cared for.

- Q: Can olive nets be used in olive groves with high bird populations?

- Olive nets can be used in olive groves with high bird populations as they are specifically designed to protect the olives from being eaten by birds. These nets act as a physical barrier, preventing birds from accessing the fruit. However, it is important to regularly monitor and maintain the nets to ensure their effectiveness and prevent any entanglement of birds.

- Q: How do olive nets affect the yield of olives?

- Olive nets can have a significant impact on the yield of olives by providing protection against pests and wind damage. These nets act as a barrier, preventing birds and insects from accessing the fruit, therefore reducing potential losses due to infestations or pecking. Furthermore, they also help prevent olive trees from shedding their fruits prematurely during windy conditions. As a result, olive nets can ultimately increase the yield of olives by improving overall fruit quality and minimizing crop losses.

- Q: Can olive nets be used on olive trees grown in containers?

- Yes, olive nets can be used on olive trees grown in containers. Olive nets are commonly used to protect olives from birds and other pests. Whether the olive tree is grown in a container or in the ground, the nets can be draped over the tree to provide protection.

- Q: What sizes do olive nets come in?

- Olive nets come in various sizes, ranging from small sizes suitable for home gardens to larger sizes suitable for commercial olive groves.

- Q: How does an olive net affect the overall fruit oil content in the olive grove?

- An olive net can positively affect the overall fruit oil content in an olive grove. By placing the netting over the trees, it prevents the olives from falling to the ground and getting damaged or contaminated. This ensures that the olives remain intact and are not exposed to external factors that could degrade their quality. Consequently, the olives harvested from the netted trees are more likely to have a higher oil content, leading to a better overall fruit oil content in the olive grove.

- Q: Can olive nets be used in high-density olive plantations?

- Yes, olive nets can be used in high-density olive plantations. Olive nets are commonly used in olive orchards to protect the olives from birds, reduce wind damage, and facilitate harvesting. They can be installed and adjusted to accommodate the specific conditions and requirements of high-density olive plantations.

- Q: How are olive nets cleaned after use?

- Olive nets are typically cleaned after use by first removing any debris or leaves from the nets. Then, they are washed using water and mild detergent to remove dirt and stains. Finally, the nets are dried thoroughly before being stored for future use.

- Q: Can olive nets be used for olive trees in greenhouses?

- No, olive nets are typically used in open fields to collect olives during harvest, not in greenhouses where olive trees are cultivated.

- Q: How does an olive net affect the overall appearance of the olive grove?

- An olive net can significantly impact the overall appearance of an olive grove. When properly installed, it creates a uniform and tidy look by covering the entire grove, concealing the tree branches and reducing the visibility of fallen leaves. The net's color, typically a vibrant green, blends in with the foliage and enhances the visual appeal of the grove. Additionally, the net's presence indicates the active harvesting season, adding a sense of liveliness and productivity to the overall appearance of the olive grove.

Send your message to us

PVC Conveyor Belt PU Conveyor Belt Food Processing Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords