PVC Conveyor Belt PU Conveyor Belt In Food Processing Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Conveyor Belt PU Conveyor Belt In Food Processing Industry

Food Grade Conveyor Belt

Food Grade Conveyor Belt Introduction

Food processing conveyor belt choose high quality high strength polyester fabric are the core, coated with PU or PVC as loading surface. With advantages of good flexibility, material environmental friendly, light duty, high tensile strength, anti oil, easy learning, our food processing conveyor belt meet EU and USA market requirements.

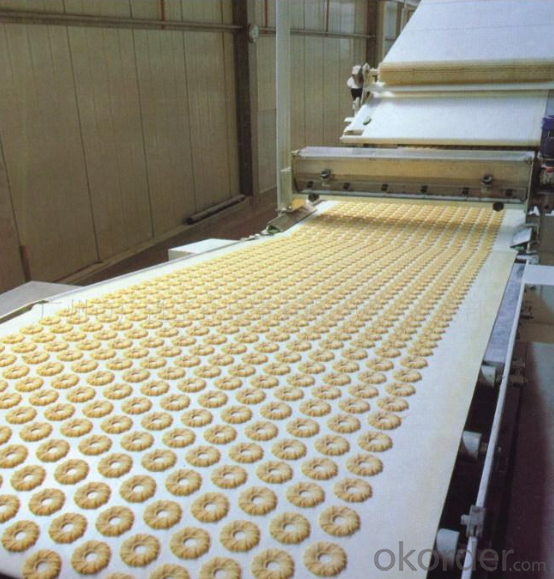

Food Grade Conveyor Belt Application

Food processing conveyor belt is widely used in food industry, such as vegetables, snack food, beer, sea food, etc.

Widely used in the Conveyance and production assembly lines in the areas of airports,

postal automation, parcel handling, treadmills, packaging/wrapping, cigarettes,tobacco,leather, foodstuffs,

drinks, medicine,chemical,tyre ,electronics, pharmaceutical, printing,papermaking, wood, stone/marble,

entertainment industry and fishery industry etc

Food Grade Conveyor Belt Advantage

Food processing conveyor belt is made of harmless material, no toxicity, no smell, anti-oil, easy cleaning, high tensile strength, good flexibility, light weight, solid and durable.

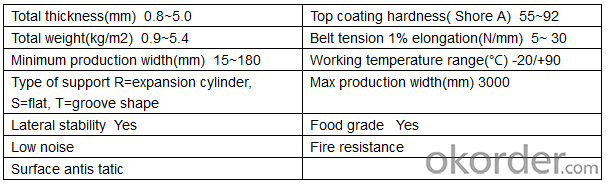

Food Grade Conveyor Belt Specifications

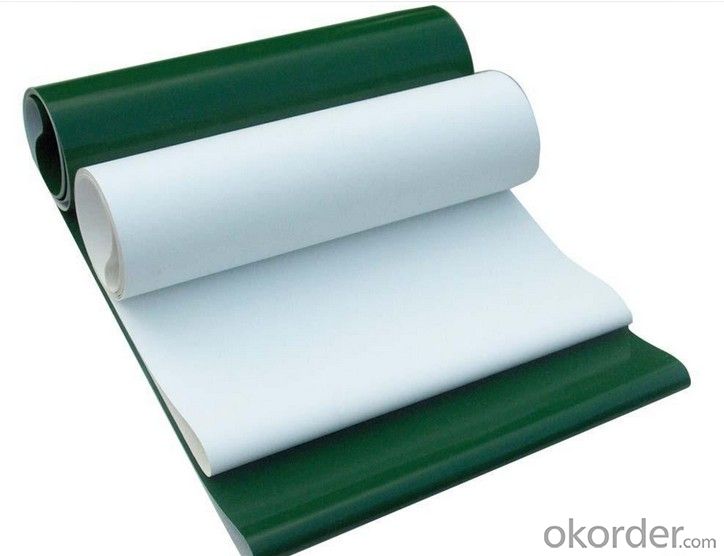

Thickness: PVC Belting (1~7mm) PU Belting (0.8~4mm)

Width: 200mm ~ 4000mm

Appearance: Flat surface, diamond pattern, lawn pattern, golf pattern,etc.

Colors: Green, blue, gray, white, black, blue, dark green, transparent,etc.

Subsequent machining technology: It can add baffle, skirt, sponge, guide bar,etc.

Food Grade Conveyor Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the

samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL,

TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the

freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to

the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the conveyor belt, you could make an Inquiry in

okorder.com. Okorder.com provides you the products with best price and quality!

- Q:Can olive nets be used on trees with a large canopy?

- Yes, olive nets can be used on trees with a large canopy. Olive nets are designed to catch the olives as they fall from the tree during harvesting. They can be spread out and attached to the branches of the tree, allowing for the collection of olives from trees with a large canopy.

- Q:Can olive nets be used for olive tree nurseries?

- Yes, olive nets can be used for olive tree nurseries. These nets are typically used to protect olive trees from pests, extreme weather conditions, and birds. They can also help maintain a controlled environment for the young olive trees, promoting healthy growth and development.

- Q:What are the main defects of common plastic products?

- Poor welding: due to the melting of material, the drop of the material temperature at the confluence, the failure of the resin and the inclusion compound, etc., causes the welding material to flow into the confluence and the welding is bad and produces a fine fine seam along the surface or inside of the plastic product.Because of the melt along the surface of the mold surface is not smooth flow to fill the cavity, but into a semi solidified state of fluctuation along the cavity surface of the melt flow or a stagnation phenomenon.Silver markings: as the material in water or air, and volatile matter too much, the melt shear effect is too large, the melt and mold surface sealing side, or rapid cooling or mixing of different materials or decomposition of metamorphism, and make plastic products surface appearance of silver white luster along the direction of flow of the needle like stripes or mica makeup markings (water traces).

- Q:When was plastic invented?

- The plastic is made of monomers as raw materials, polymer by polyaddition or polycondensation polymerization (macromolecules), commonly known as plastic resin (plastics) or (resin), can freely change the composition and form style, composed of synthetic resin and filler, plasticizer, stabilizer, lubricant, pigment and other additives.

- Q:Can olive nets be used in areas with saltwater exposure?

- Yes, olive nets can be used in areas with saltwater exposure. These nets are typically made from high-quality materials that are resistant to corrosion and can withstand the effects of saltwater. However, it is important to regularly inspect and maintain the nets to ensure their longevity and effectiveness in such environments.

- Q:Can olive nets be used on olive trees grown in raised beds?

- Yes, olive nets can be used on olive trees grown in raised beds. Olive nets are commonly used to protect the tree's fruit from birds and other animals, regardless of whether the trees are grown in raised beds or in the ground. They provide a physical barrier that prevents pests from accessing the fruit, ensuring a higher yield and better quality harvest.

- Q:How much sunlight do olive nets allow through?

- Olive nets typically allow around 50-70% of sunlight to pass through.

- Q:Can olive nets be used in small backyard olive trees?

- Yes, olive nets can be used in small backyard olive trees to protect the harvested olives from birds and other pests.

- Q:How do olive nets prevent olives from being damaged by windstorms?

- Olive nets prevent olives from being damaged by windstorms by providing a protective barrier that prevents the olives from being blown off the tree. The nets are securely fastened around the tree, creating a shield against the strong winds. This helps to ensure that the olives remain intact and do not get scattered or bruised during severe weather events.

- Q:Can olive nets be used in areas with strong winds?

- Yes, olive nets can be used in areas with strong winds. However, it is important to ensure that they are properly secured to withstand the force of the wind. Additional anchoring or reinforcement may be necessary to prevent the nets from being damaged or blown away.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Conveyor Belt PU Conveyor Belt In Food Processing Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords