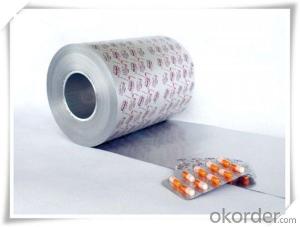

Aluminum Foil for Blister Packs

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 7000MT/MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick details of Aluminium Foil For Blister

Alloy: 8011/8006/8079

Temper: H18/O

Specifications of Aluminium Foil For Blister

Thickness & Tolerance: 0.02mm-0.09mm (±6%)

Width & Tolerance: 200 - 1650 mm (+/-1 mm)

Mechancial Properties: Tensile Strength(U.T.S)≥160Mpa, Elongation≥1%

Standard: GB/T3198 / ASTM-B209 / EN546

Usage/Application of Aluminium Foil For Blister

For PTP foil, cord-forming foil, alu-alu foil

Packaging & Delivery of Aluminium Foil For Blister

Packing: seaworthy wooden box with pallet

Delivery: to be loaded by 1 x 20 feet container

- Q: Explain the distinction between pure aluminum and aluminum alloys, focusing on their composition and properties.

- <p>Pure aluminum is composed of aluminum alone, with a high degree of purity, typically over 99%. It is soft, malleable, and has good thermal and electrical conductivity. Aluminum alloys, on the other hand, are made by combining aluminum with other elements such as copper, magnesium, or silicon to enhance their strength, durability, and resistance to corrosion. These alloys are harder than pure aluminum and can be tailored for specific applications, making them more versatile for industrial use.</p>

- Q: Is it possible to create jewelry using aluminum as the primary material?

- <p>Yes, aluminum can be used to make jewelry. It is a lightweight, durable, and affordable metal that is often used in costume jewelry and fashion accessories. Aluminum's low cost and ease of shaping make it a popular choice for designers looking for a versatile material that can mimic the look of more expensive metals. However, it is not as strong or valuable as precious metals like gold or silver, and it may not be suitable for fine jewelry due to its lower durability and potential for oxidation.</p>

- Q: This question asks about the environmental effects caused by the extraction and processing of aluminum.

- <p>The environmental impacts of mining and processing aluminum are significant. Mining can lead to deforestation and habitat destruction, affecting biodiversity. The process of bauxite extraction releases large amounts of greenhouse gases, contributing to climate change. Additionally, the production of aluminum is energy-intensive, often relying on fossil fuels, which further exacerbates environmental issues. The release of toxic chemicals and heavy metals during processing can contaminate soil and water, posing risks to both ecosystems and human health. Moreover, the waste generated, such as red mud, can cause severe environmental damage if not properly managed. Overall, the aluminum industry has a substantial environmental footprint that requires sustainable practices to mitigate its effects.</p>

- Q: Can aluminum be recycled repeatedly without losing its quality or strength?

- <p>Yes, aluminum can be recycled multiple times without significant degradation in quality or strength. The recycling process retains most of its original properties, making it one of the most sustainable materials. Each recycling cycle does not diminish its performance, unlike some other materials. This characteristic makes aluminum a valuable resource in reducing waste and conserving energy.</p>

- Q: This question asks for examples of industrial processes that incorporate the use of aluminum.

- <p>Aluminum is widely used in various industrial processes due to its lightweight, corrosion resistance, and high strength-to-weight ratio. Some key industrial processes that utilize aluminum include the automotive industry for manufacturing car parts, the aerospace industry for aircraft construction, the construction industry for building materials, the packaging industry for food and beverage cans, and the electronics industry for components in devices. Aluminum is also used in the manufacturing of machinery, electrical equipment, and transportation equipment. Its versatility makes it a crucial material in many industrial applications.</p>

- Q: Explain how the inclusion of copper impacts the characteristics of aluminum alloys.

- <p>The addition of copper to aluminum alloys significantly enhances their strength and hardness. Copper is one of the most effective alloying elements for aluminum, leading to the formation of a series of age-hardenable alloys known as the 2xxx series. These alloys, such as 2024, are characterized by their high strength-to-weight ratio and are often used in aerospace applications, structural components, and transportation equipment. The copper atoms in the aluminum matrix form precipitates that strengthen the alloy through a process called precipitation hardening. However, the addition of copper also reduces the alloy's ductility and corrosion resistance, necessitating careful control of the copper content and heat treatment processes to optimize the alloy's properties for specific applications.</p>

- Q: Is it possible to recycle aluminum cans to create new ones?

- <p>Yes, old aluminum cans can be recycled to make new ones. The recycling process for aluminum is highly efficient and environmentally friendly. Aluminum cans are collected, sorted, and then shredded into small pieces. These pieces are melted down in a furnace, and the molten aluminum is poured into molds to create new cans. This process uses only 5% of the energy required to produce aluminum from raw materials, making it a sustainable and cost-effective method of production.</p>

- Q: This question asks about the reactivity of aluminum with various substances, including its chemical reactions and properties.

- <p>Aluminum is a highly reactive metal that readily reacts with oxygen to form a protective layer of aluminum oxide on its surface. It can also react with acids, such as hydrochloric or sulfuric acid, to produce hydrogen gas and aluminum salts. In the presence of a strong base, aluminum can react to form aluminates and hydrogen gas. Additionally, aluminum can reduce certain metal oxides, such as iron oxide, in a thermite reaction. However, due to its reactivity, aluminum is often used in alloys with other metals to improve its strength and corrosion resistance.</p>

- Q: Is it possible to use aluminum as a material in the construction of solar panels?

- <p>Yes, aluminum is commonly used in solar panels. It is utilized in the frame of the solar panel to provide structural support and protection. Aluminum is chosen for its lightweight, high strength, and resistance to corrosion, which are beneficial properties for outdoor applications like solar panels. It also helps in heat dissipation, which is crucial for maintaining the efficiency of the solar cells. While aluminum is not a primary component of the photovoltaic cells themselves, its role in the overall structure is significant.</p>

- Q: Is there any risk to health from consuming food wrapped in aluminum foil?

- <p>Eating food wrapped in aluminum foil generally does not pose significant health concerns under normal circumstances. Aluminum is a stable element and does not leach easily into food at room temperature. However, at high temperatures, such as during grilling or baking, small amounts of aluminum might migrate into food. Most studies suggest that the amount of aluminum ingested from food wrapped in foil is minimal and not harmful. Nonetheless, it's advisable to avoid wrapping acidic foods or using foil in direct contact with food at high temperatures to minimize any potential exposure.</p>

Send your message to us

Aluminum Foil for Blister Packs

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 7000MT/MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords