Aluminium Foil Paper

Aluminium Foil Paper Related Searches

Aluminum Paper Foil Aluminum Foil Wrapping Paper Aluminum Foil Paper Roll Aluminum Foil Sheet Printed Aluminum Foil Aluminum Foil Kraft Paper Aluminum Foil Leaves Aluminum Foil Paper Price Gold Aluminum Foil Paper Printable Aluminum Foil Aluminum Foil Plate Aluminum Foil Foam Aluminum Wrapping Foil Sheet Of Aluminum Foil Aluminum Foil Baking Sheet Aluminum Foil For Packaging Aluminum Foil Wrap Sheets Aluminum Foil Packets Al Aluminum Foil Aluminum Foil Rolls Baking Aluminum Foil Art Aluminum Foil Aluminum Tin Foil Paper Cut With Aluminum Foil Aluminum Foil Packs Aluminum Foil Box Baking Sheet Aluminum Foil Aluminum Tooling Foil Printing On Aluminum Foil Aluminum Foil CoatedAluminium Foil Paper Supplier & Manufacturer from China

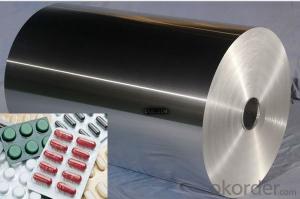

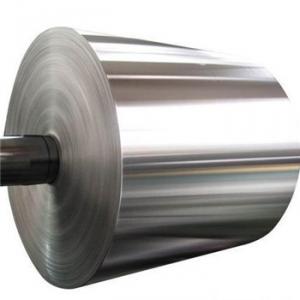

Aluminium Foil Paper is a versatile product made from a thin layer of aluminum bonded to a paper substrate. This material is known for its excellent barrier properties, making it ideal for various applications that require protection against moisture, air, and light. It is commonly used in food packaging, pharmaceuticals, and industrial applications due to its ability to preserve freshness and extend shelf life.Aluminium Foil Paper is widely used in a variety of scenarios, such as food packaging to keep food items fresh and protected, or in pharmaceuticals to maintain the integrity of sensitive medications. It is also utilized in industrial settings for insulation and as a barrier against corrosive substances. The product's unique properties make it a popular choice for a multitude of uses, ensuring that the contents remain safe and secure.

Okorder.com is a leading wholesale supplier of Aluminium Foil Paper, boasting a vast inventory to cater to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Aluminium Foil Paper supplied is of the highest standard, making it a reliable choice for businesses and individuals alike.

Hot Products