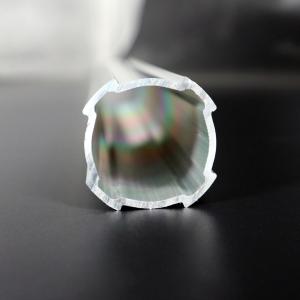

Ribbed Aluminum Plate

Ribbed Aluminum Plate Related Searches

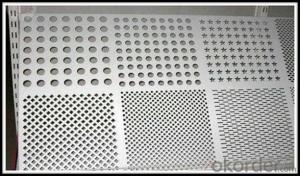

Rolled Aluminum Plate Milled Aluminum Plate Textured Aluminum Plate Aluminum Threaded Plate Rubber Backed Aluminum Plate Aluminum Round Plate Machined Aluminum Plate Slotted Aluminum Plate Polished Aluminum Plate Aluminum Metal Plate Aluminum Ramp Plate Aluminum Profile Plate Extruded Aluminum Plate Aluminum Dimond Plate Aluminum Grill Plate Grooved Aluminum Plate Aluminum Paper Plate Bending Aluminum Plate Aluminum Wall Plate Aluminum Cover Plate Aluminum Thread Plate Drilled Aluminum Plate Brushed Aluminum Plate Perforated Aluminum Plate Embossed Aluminum Plate Aluminum Spinning Plate Aluminum Mold Plate Corrugated Aluminum Plate Wrought Aluminum Plate Aluminum Grid PlateRibbed Aluminum Plate Supplier & Manufacturer from China

Ribbed Aluminum Plate is a type of aluminum sheet material characterized by its distinctive ribbed pattern. This unique design provides added strength and rigidity, making it an ideal choice for various applications. The ribbed pattern also offers improved traction and slip resistance, making it suitable for environments where safety is a priority.Ribbed Aluminum Plate is widely used in a range of industries, including construction, transportation, and manufacturing. It is commonly employed in the production of truck beds, flooring systems, and roof decking due to its durability and resistance to corrosion. Additionally, its slip-resistant surface makes it a popular choice for walkways, ramps, and other areas where foot traffic is heavy. The versatility of Ribbed Aluminum Plate allows it to be used in both indoor and outdoor settings, making it a valuable asset in a variety of applications.

Okorder.com is a leading wholesale supplier of Ribbed Aluminum Plate, offering a vast inventory to meet the demands of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that each order of Ribbed Aluminum Plate is of the highest standard. By partnering with Okorder.com, customers can rely on a consistent supply of this essential material, ensuring that their projects are completed on time and within budget.

Hot Products