Aluminum Pipes Wooden Coating Aluminum Coils for Ceiling Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Wooden Coating Aluminium Coils for Ceiling Tiles

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Wooden Coating Aluminium Coils for Ceiling Tiles

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Wooden Coating Aluminium Coils for Ceiling Tiles

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

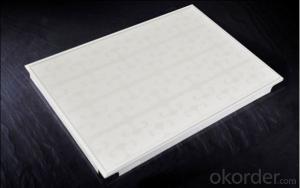

5. Image of Wooden Coating Aluminium Coils for Ceiling Tiles

6. Package and shipping of Wooden Coating Aluminium Coils for Ceiling Tiles

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: We bought the house in 2008 Frestech refrigerator, 2 door, 179L, when the price is 1700 yuan. It's been four and a half years now. The refrigerator is broken. The refrigeration began to heat up in three hours, and the meat in the freezer became soft and soft. Call the customer service, please master home repair, the master told us that the cooling pipe corrosion leak, to add 450 yuan for copper pipe. Also said that after 2008 refrigerators produced, the basic cooling tube is iron or aluminum, in order to control costs. After the bad, you have to pay additional money to buy a new refrigerator, so as to update. Otherwise, like the previous refrigerator is copper tube, 20 years are not bad, manufacturers are unable to survive. Alas, are manufacturers today so black hearted?

- Frestech refrigerator belongs to the second tier brands, with the greatest likelihood of iron pipe.At present, the domestic refrigerators are basically aluminum alloy tubes or iron pipes, the main reason is to reduce costs. In addition, the current refrigerant does not have any corrosive, and iron pipe is entirely possible.However, the exposed section, that is, the section of the compressor links, or copper tube, because it leaks in the air, the cold pipe will condense the moisture in the air, forming water droplets, if the iron pipe, it will rust easily. The main pipe is insulated by the insulation layer and is not in contact with the air. Therefore, the water pipe can not be collected, and the iron pipe is feasible.

- Q: The same size or different specifications of the square aluminum tube, T how to connect more beautiful ah?!

- Aluminum tube is a kind of nonferrous metal pipe, which is made of pure aluminum or aluminum alloy and is extruded into a hollow metal tube with longitudinal length.There may be one or more closed through holes with uniform wall thickness and cross section to be delivered in a straight or coiled form. Widely used in automobiles, ships, aerospace, aviation, electrical appliances, agriculture, machinery and electrical, home and other industries.

- Q: What is the difference between air conditioning copper tubes and aluminum tubes?

- The copper tube has high heat transfer efficiency, corrosion resistance and good strength, but the price is expensive.The heat transfer efficiency of aluminum pipe is higher, the corrosion resistance is not good, but the price is much cheaper.

- Q: What are the different wall thickness options for aluminum pipes?

- The different wall thickness options for aluminum pipes can vary depending on the specific needs and requirements of a project. However, commonly available wall thickness options for aluminum pipes range from thin-walled pipes with a thickness of around 0.065 inches (1.65 mm) to thicker-walled pipes that can go up to 0.5 inches (12.7 mm) or more. It's important to consult with manufacturers or suppliers to determine the most suitable wall thickness for your specific application.

- Q: When I repair the refrigerator, I often encounter leakage in the aluminum pipe. It can not be repaired by conventional wind welding. What is the best way to repair it?

- Leak Sassafras net, with the "good brothers" with strong, good results.

- Q: How can the aluminum tube bending be processed and how to make manual bending equipment?

- How to make manual bending equipment?A guide wheel is additionally provided with a lever to apply the rod to rotate the force in the center of the guiding wheel.

- Q: Does the air conditioner have a good copper tube or an aluminum tube?

- It must be copper pipe! The aluminum tube doesn't last long, and it doesn't work. Only the copper tube can be welded

- Q: Can aluminum tubes be used instead of compressed air pipes?

- Definitely.In principle, as long as the strength and performance indicators are adequate, then many materials are available, and aluminum is no exception.In fact, there are special tubes for air compression pipes, such as these

- Q: Can aluminum pipes be used for gas transportation?

- Gas transportation can indeed utilize aluminum pipes. Renowned for its lightweight and robust nature, aluminum boasts exceptional corrosion resistance. Consequently, this material finds widespread application across diverse industries, including gas transportation, thanks to its capacity to endure elevated pressure and temperature circumstances. Furthermore, handling and installing aluminum pipes prove more convenient than their steel counterparts. Nonetheless, it remains crucial to ensure adequate coating or lining of the aluminum pipes to avert any potential interaction between the gas and the metal, as certain gases may react unfavorably with aluminum.

- Q: Which is faster, the aluminum tube and the copper tube radiator on the computer?

- What you said is the tube heat pipe, the color is not the same, there is a layer of plating antioxidant things, Caifen fin copper and aluminum, aluminum heat sink cooling seems better. Full copper, the weight will be heavier, the main pressure on the motherboard will be relatively large.

Send your message to us

Aluminum Pipes Wooden Coating Aluminum Coils for Ceiling Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords