Aluminum Coated Lidding Film

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 15 Tons Per Day kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

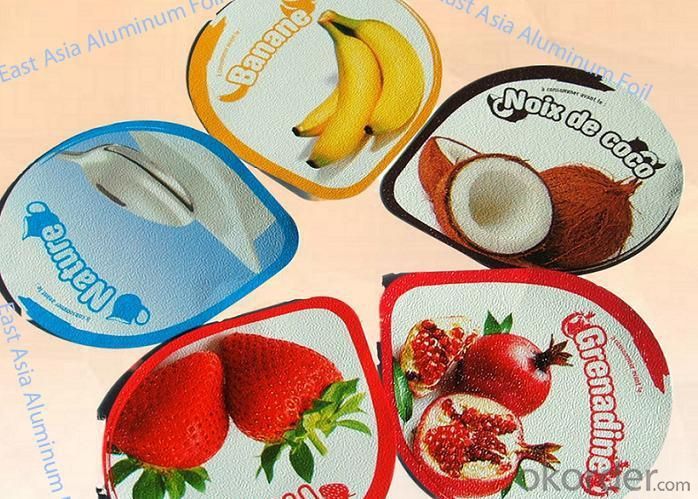

1. Specifications of Multi-layer Coated lidding film:

Film structure: AL/coating

High barrier performance

Good high and low temp. resistance

Excellent sealing performance

Coated Aluminum foil or embossed

Thickness:20-200um

Width:30-300cm

Length:1500-3000m

Notice: Special products made as per customer requirements.

2. Usage of Multi-layer Coated lidding film:

Multi-layer Coated lidding film is widely used in dairy, processed food, medicine etc for lid sealing.

3. Packaging & Delivery of Multi-layer Coated lidding film:

One 20GP container can be loaded about 10-15tons.

By sea or by air all available.

- Q: What packing materials should be understood in purchasing?

- Other specific products, specific problems specific analysis, because the product form is not the same, liquid or chemical products packaging is not the same, the general small commodities, daily necessities of packaging almost the same

- Q: What are the characteristics of paper holders in comparison with other packaging materials?

- The first is the protection of the environment, paper packaging raw material is waste paper pulp, not only has no pollution to the environment, but also conducive to conserve resources, protect the environment. The use range of paper tray is very extensive, with the improvement of technology paper,

- Q: What are biodegradable packaging materials?

- Biodegradable packaging has a bright future and has attracted worldwide attention. In this paper, the properties, degradation mechanism, processing technology and application of various kinds of degradable packaging materials are reviewed. According to the mechanism of degradation, it can be divided into biodegradable plastics, biodegradable plastics, light / biological double degradable plastics and water degradation plastics.

- Q: What are the common material choices, printing options and common sense?

- Moon high-end gift box: the use of 157G coated paper laminating grey board or board, can also be wove paper or other special craft paper.Printing: more 4C+0 printing, can be printed spot color (special gold or silver).After the process: light glue, matte plastic, local UV, matte, hot embossing, platinum (metallic film with gold, silver, blue and other colors for choice) or anti-counterfeit film (so that others can not copy), box mounted silk cloth, sponge or foam flocking plastic etc. material. Most of the handicraft is made by hand, and the materials should be chosen according to the needs and grades of the products. It has the artistic taste of elegant and elegant appearance.

- Q: What is accessory material? What is the difference between it and raw material?

- Auxiliary materials are indirect materials used in manufacturing and in manufacturing, but not the main products of the product.

- Q: Which industry does the packing product belong to?

- Other countries or organizations have different meanings and opinions about the meaning of packaging, but the basic meaning is consistent. They all take the function and function of packaging as their core contents and have two meanings in general:1. Containers, materials and auxiliary articles that contain the goods, that is, packages.2, on the implementation of containing and sealed, dressing and other technical activities.

- Q: What are the categories of packing materials?

- Composite soft packing material: soft packaging, film, core wire, aluminum foil composite film, vacuum aluminum plating paper, composite film, composite paper, BOPP; metal packaging materials: tin foil, strip, hoop, packing buckle, Blister aluminum, aluminum foil, aluminum plate, steel buckle PTP;

- Q: What plastic packaged food is safer?

- If you do not want to contact the high temperature, you can also choose PET materials and PS materials, these two can contact food directly.

- Q: What are the commonly used packing materials?

- Paper packing material: wrapping paper, honeycomb paper, paper bag paper, desiccant packing paper, honeycomb paperboard, kraft paper, industrial paperboard, honeycomb paper corePlastic packing material: sealing film, shrink film, plastic film, winding film, heat shrinkable film, hollow board, POF shrink film, CPP, EPP

- Q: Is the antistatic value of PS material (or other packing material) as small as possible?

- PS materials need special antistatic agent, Wuxi giant plasticized material has an antistatic agent, good, can be used in ABS, GPPS, HIPS, PPS, EPS and so on, the effect is good.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 1999 |

| Annual Output Value | Above US$ 450 Million |

| Main Markets | Mid East, Eastern Asia, Africa, Eastern Europe, Southeast Asia |

| Company Certifications | National Industrial Products Production License |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Guangdong |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 200-300 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 350,000 square meters |

| No. of Production Lines | Above 20 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High |

Send your message to us

Aluminum Coated Lidding Film

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 15 Tons Per Day kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords