JPN-5000 Automatic Piston Filling Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ⅰ、Introduction

1.1 The machine adopts PLC and touch screen automation control, with accurate measurement, advanced structure, smooth operation, low noise, large adjustment range, the filling speed, etc. .

1.2 The delicate servo system precisely control the filling amount with precise piston stoke provides high filling accuracy, intelligent piston is designed with miner adjusting mechanism enable users to adhesive ultimate higher accuracy.

1.3 the application of touch-screen technology, the operation of the machine is more reliable, convenient and human-machine interface more friendly. Photoelectric sensors, proximity switches, etc. are used in advanced sensing elements, so no bottle no filling, plugging bottles will automatically stop and alarm.

1.4 filling way with dive style, using different materials seal rings, to meet the different characteristics of the filling material.

1.5 the machine produced according to GMP standards , all piping connections using quick way to disassemble and clean convenient location and contact with the material exposed parts are made of high quality stainless steel , machine safety, environmental protection , health, beauty, able to adapt a variety of work in different environments.

1.6 This filling machine is widely used for food, pharmaceutical, chemical, cosmetics and various industries.

Ⅱ、Feature

2.1 Controlled by Panasonic servo system.

2.2 Controllable and various filling speed.

2.3 Integrated digital control with MITSUBISHI PLC and Touch Screen controls

2.4 Designed for easy change-over and cleaning.

2.5 GMP standard Stainless Steel.

2.6 No bottle-no fill system.

2.7 Quick change of volume with digital readout.

2.8 Individual piston adjustment for fine tuning.

2.9 Adjustable speed while filling, it can fill slowly at the beginning and then accelerate to faster speed, finally slow down once again to finish up. This can prevent foamy liquids from bubbling and avoid spillage.

Ⅳ、Specifications:

4.1 Filling Capacity:500cc-5000cc

4.2 Model :JPF-4A/6A/8A

4.3 Filling Heads :4/6/8

4.4 Filling error:±0.5%

4.5 Power:2.5kw

4.6 Speed:≤2000B/H

4.7 Air source: 0.6Mpa——0.8Mpa clean and stable air source

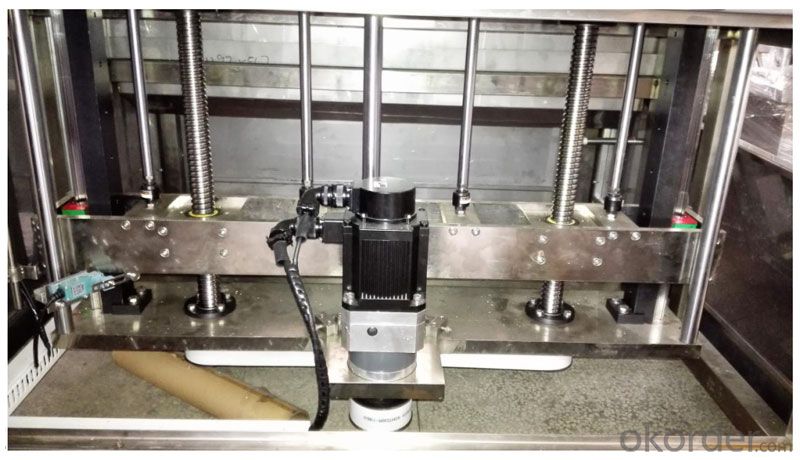

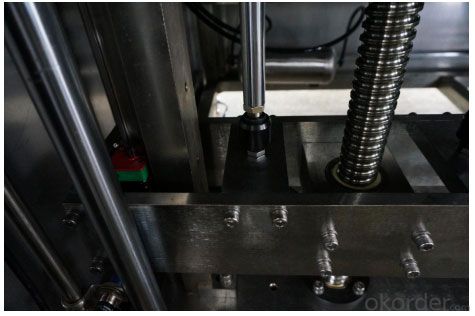

Ⅴ、Images

FAQ

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

- Q: What are the packing materials for heavy cargo transportation?

- Common transport packaging materials are: lining board, foam plastic, air cushion film, air cushion film, other fillers and so on.

- Q: What packing materials should be understood in purchasing?

- Other specific products, specific problems specific analysis, because the product form is not the same, liquid or chemical products packaging is not the same, the general small commodities, daily necessities of packaging almost the same

- Q: What's the difference between bulk food and prepackaged food?

- Is a small workshop to provide containers, that is, pre packaged food, is to take their own containers to buy, that is, bulk food

- Q: What are the characteristics of paper holders in comparison with other packaging materials?

- The first is the protection of the environment, paper packaging raw material is waste paper pulp, not only has no pollution to the environment, but also conducive to conserve resources, protect the environment. The use range of paper tray is very extensive, with the improvement of technology paper,

- Q: What are biodegradable packaging materials?

- Synthetic biodegradable packaging materials can be endowed with similar properties as traditional packaging materials, and the wide application of biodegradable packaging indicates its great potential to replace the current packaging materials.

- Q: Which industry does the packing product belong to?

- Other countries or organizations have different meanings and opinions about the meaning of packaging, but the basic meaning is consistent. They all take the function and function of packaging as their core contents and have two meanings in general:1. Containers, materials and auxiliary articles that contain the goods, that is, packages.2, on the implementation of containing and sealed, dressing and other technical activities.

- Q: What are the sales packing materials?

- Sales packing is also called inner packing or small package. Is the direct contact with the goods and goods into retail outlets and consumers or users directly to meet the packaging. Adapt to the competition in the commodity market and meet the multi-level consumption requirements, and constantly send to the sales packaging requirements, improvement and innovation information. This information is not only for the sales package, but also refers to the packaging industry; no synchronous development of each professional packaging and improve sales package will be in the "bricks without straw" situation.

- Q: What plastic packaged food is safer?

- If you do not want to contact the high temperature, you can also choose PET materials and PS materials, these two can contact food directly.

- Q: What's the difference between the materials used in kraft paper packaging?

- Semi Kraft kraft wrapping paper: General tensile, color is also very general, if there is no requirement for appearance, you can use semi wood pulp, kraft paper.

- Q: Is the antistatic value of PS material (or other packing material) as small as possible?

- Not necessarily. This needs to be decided in terms of specific areas of use and requirements.The so-called antistatic refers to reach 10 between the 7-10 sides.And the 1-6 side of the 10 is generally referred to as electrical conduction.

Send your message to us

JPN-5000 Automatic Piston Filling Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords