Automatic Filling Machine for Packaging Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

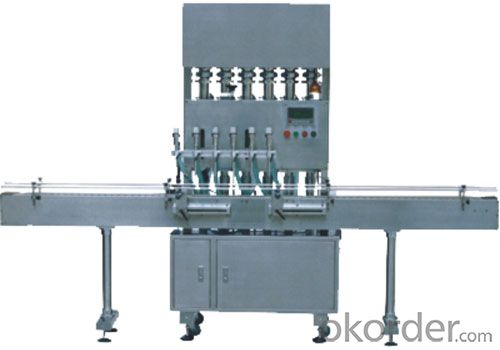

Automatic Filling Machine for Packaging Industry

1. Product Description:

Bottles are entered by the air conveyor, the speed of bottle entering is fast and bottle shape isn’t changed because of adopting hanging clamping bottleneck way. Adopting clamping bottleneck fashion to wash bottle mouth and avoid touching screw mouth, when bottle type changes, you need to change the board related with bottle diameter. Filling adopts cylinder feeding structure, filling valve adopts high filling speed and mass flow rate valve which control liquids level accurately and without loss. Screw capper adopts French advanced technologies which can screw cap promptly when clamping bottle.

2. Product Features:

Rinser / filler / capper monobloc

Bottle material: PET, glass, metal

Bottle volume: 250ml - 2500ml

Production capacity: 2000-15000bph

We Can design according to customers' demands

We can supply complete filling line solution and filling machines for carbonated soft drinks

3. Product Parameters:

Model | DGZ14-12-5 | DGZ18-18-6 | DGZ24-24-8 | DGZ32-32-8 | DGZ40-40-10 |

Production Capability | 2000-3000 | 4000-6000 | 7000-8000 | 8000-12000 | 12000-15000 |

Filling precision | ≤+5mm(Liguid Level) | ||||

Filling pressure | ≤0.4 | ||||

PET bottle specification | (Bottle diameter):Ø50- Ø100;(Height):150-310 | ||||

Suitable cap shape | Plastic Screw Cap | ||||

Total Power(kw) | 2.2 | 3.5 | 4.5 | 5.5 | 5.5 |

Washing heads | 14 | 18 | 24 | 32 | 40 |

filling heads | 12 | 18 | 24 | 32 | 40 |

4. FAQ:

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

5. Product Pictures:

- Q: Where is secondhand corrugated paper packaging machinery available?

- And in the packaging materials, carton packaging accounted for a large part of the weight.Therefore, the carton factory is still very optimistic about the prospects.Business is best to have their own, if not, it is like playing a battle without vigor.But if you have better personal skills, you can also sell it to someone else's factory.After all, it is impossible to have friends and relatives need cartons, no "relationship" can be bigger and stronger.

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Well, yesBut the vacuum packaging machines used for different product sizes are different

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- A small object, small particle, powder, crystal, liquid, suitable for packing

- Q: Bread packing machine Product features

- Product features1. double frequency control, bag length is cut, no need to adjust the empty walk, one step in place, save time and save the film.2. man-machine interface, parameter setting is convenient and quick.3. fault diagnosis function, clear failure display.

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- Change a new one, in fact, the knife is very simple, and the ordinary knife is very cheap.If you don't understand, you can ask me

- Q: What kind of reducer is commonly used in packaging machinery?

- Generally speaking, gear reducer, planetary gear reducer, and the most common one, these equipment power is relatively small, and some need to take the brakes of the motor reducer

- Q: What is the working principle of the pillow packing machine?

- Some packaging machinery manufacturers, many varieties of products, in the purchase of packaging machines, I hope a device can pack all their own varieties

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Different conceptsCompression molding refers to hot forming: mainly for thermoplastic materials (sheet), the use of hot forming machine, Blister molding, I think it should also be considered as a branch of hot stamping, vacuum or high-pressure gas will be used to assist. Hot pressing sheet forming a relatively small depth, relatively simple structure, low precision products, such as packaging materials, plastic pallets, plates in the dishes and so on. There are also forming plate pressing molding (lamination)

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- Hygienic standard for polyethylene terephthalate resin for GB 13114 food containers and packaging materialsGB, 13113-1991. Hygienic standard for polyethylene terephthalate molded articles for food containers and packaging materials

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

Automatic Filling Machine for Packaging Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords