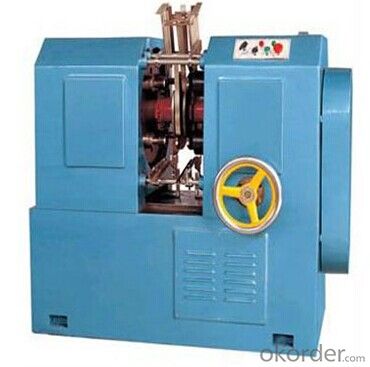

Aerosol Can Body Necking and Flanging Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description:

Aerosol Can Body Necking and Flanging Machine Usage and Applications

Type:Packaging Line

Condition:New

Application:Machinery & Hardware

Packaging Type:Cans

Packaging Material:Metal

Automatic Grade:Automatic

Driven Type:Electric

Voltage:380V

Place of Origin:Zhejiang, China (Mainland)

Model Number:GT10A6

Dimension(L*W*H):6650*3880*1530mm

Weight:6700KG

Certification:CE

Aerosol Can Body Necking and Flanging Machine Main TechnicalParameters

| Name | Aerosol Can Body Necking & Flanging Machine |

| Usage | It's used for can body necking & flanging. |

| Capacity | 60-160 cans/min |

| Applicable Can Diameter | 40-100 mm |

| Applicable Can Height | 654-280 mm |

| Power | 2.2KW,380V, 50HZ |

| Weight | 1500kg |

| Dimension | 1700*700*1300 mm |

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- Wrapping machinery should have rolling, holding, brushing, packaging machinery, bagging, weighing, sealing.

- Q: Bread packing machine Product features

- Bread packing machine, also commonly known as pillow type packaging machine. Among them, the suitable packing bread model has CM-320 pillow type packing machine, CM-400 pillow type bread packing machine

- Q: Color code positioning of packaging machinery

- The use of the printed color packaging materials, photoelectric switch (available on the color electric eye tracking and positioning), through the control system to drive the stepper motor rotation and color according to the distance between the automatic stop, to complete and accurate packaging products logo.

- Q: Working principle of packing machine

- In the first step, the wrapping paper is pulled down by a bag pulling motor, and then the paper part is supplied with paper according to the signal of the paper feeding sensor, and the wrapping paper is formed through the forming part of the shaper

- Q: What's the best place to use the pillow type packing machine?

- This device is now relatively mature technology, but each manufacturer's design is still a little different

- Q: What is the name of the paper used in packing machine parts and yellow?

- Rust preventive action, commonly used for steel vapor rust preventive paper, but also for a variety of metals.

- Q: What are the packaging machines that use temperature control watches?

- Direct heating sealing machine, blister packing machine, plastic sealing machine, heating pot, oven, toaster and so on

- Q: What does the mechanical equipment include?

- Track roller type rail flat car track car battery car nailThese are, want to know more, you can go to the network building equipment to see there

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard specifies the terms and definitions, models, types and basic parameters, technical requirements, test methods, inspection rules and signs, packaging, transportation and storage requirements of the three-dimensional packaging machine for transparent film.

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

Aerosol Can Body Necking and Flanging Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords