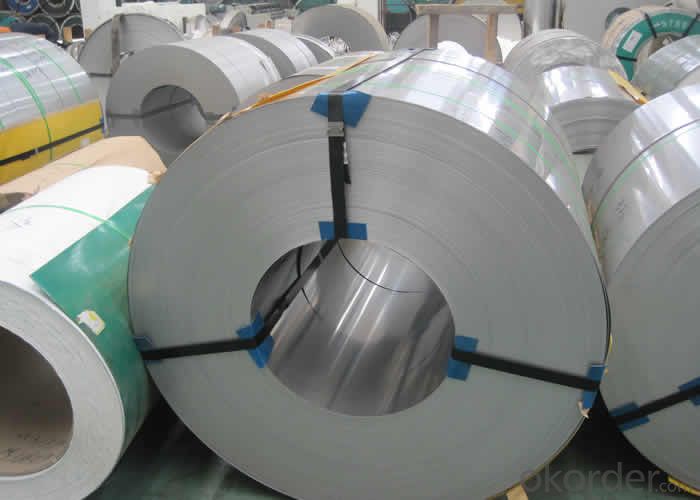

Hot Rolled Stainless Steel Coil 201 Narrow Strip No.1 Finish

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Stainless Steel Coil 201 Narrow Strip No.1 Finish

Hot Rolled Stainless Steel 201 half copper Chemical Composition(%) |

| |||||||

C | Si | Mn | P | S | Ni | Cr | Cu |

|

0.1 | 0.5 | 10 | 0.04 | 0.01 | 1.20/1.30 | 13.00/14.00 | 0.8/1.0 |

|

Grade: | 200 Series | Standard: | JIS,AISI,ASTM,GB,DIN | Thickness: | 2.5/3.0/4.0mm |

Width: | 485/510/550/610/1010/1240mm | Place of Origin: | Shanghai China (Mainland) | Brand Name: | CNBM |

Model Number: | 201 | Technique: | Hot Rolled | Application: | Industrial tubes/kitchen/bath |

Certification: | ISO | THK: | 2.5/3.0/4.0mm | Face: | No.1 |

Usage: | tubes/kitchen/bath | Origin: | CHINA | ||

Packaging Detail: For customer's requirement

Delivery Detail:10-30days

201 Hot Rolled Stainless Steel Coil Specifications

THK:2.3/2.5/3.0/4.0mm

Width:485/510/550/610/1010/1240mm

Face:No.1

201 Hot rolled stainless steel Coil Application

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.

201 hot rolled stainless steel coil, use to produce cold rolled stainless steel coil and stainless steel tube, pipe.

201 Hot Rolled Stainless Steel Coil

Strength Of Extension:100,000 To 180,000 Psi;

Yield Strength:50,000 To 150,000 Psi

Elongation :55 To 60%;

Modulus Of Elasticity:29,000,000 Psi;

Density :.280lbs/Cubic Inch(7.93g/Cm3)

- Q: What are the different grades of stainless steel used for strips?

- The different grades of stainless steel used for strips can vary depending on the specific application and requirements. Some commonly used grades include 304, 316, 430, and 201. Each grade has its own unique properties and characteristics, such as corrosion resistance, strength, and heat resistance. The selection of the grade depends on factors like the environment, load-bearing capacity, aesthetic appeal, and cost considerations.

- Q: Are stainless steel strips magnetic?

- Yes, stainless steel strips can be magnetic or non-magnetic, depending on the specific type of stainless steel used. Stainless steel is an alloy that contains iron, which is inherently magnetic. However, the addition of certain elements such as nickel or manganese can alter the magnetic properties of stainless steel. Stainless steel strips that have a higher nickel content, such as the popular 304 or 316 grades, are generally non-magnetic. On the other hand, stainless steel strips with lower nickel content, such as the 400 series, can be magnetic. Therefore, it is important to consider the specific grade and composition of the stainless steel strip when determining its magnetic properties.

- Q: Are stainless steel strips resistant to abrasion and wear?

- Stainless steel strips, in general, possess resistance to abrasion and wear. Their durability and strength are well-known characteristics that make them highly resistant to damage from friction and contact with other surfaces. This resistance can be attributed to the unique properties of stainless steel, including its high corrosion resistance, hardness, and toughness. Consequently, stainless steel strips are suitable for a wide range of applications that involve exposure to abrasive environments or high levels of wear, such as in the automotive, construction, and industrial sectors. Nevertheless, the degree of resistance to abrasion and wear may vary depending on the specific grade and surface finish of the stainless steel strip, as well as the type of abrasives or wear mechanisms involved. To ensure the appropriate selection and use of stainless steel strips for particular applications, it is advisable to consult the manufacturer's specifications and guidelines.

- Q: Can stainless steel strips be used in chemical pumps?

- Yes, stainless steel strips can be used in chemical pumps. Stainless steel is highly resistant to corrosion and can withstand exposure to various chemicals. It is commonly used in the construction of chemical pumps and other equipment that comes into contact with corrosive substances. The use of stainless steel strips ensures the durability and longevity of the pump, making it suitable for handling different types of chemicals.

- Q: What is the maximum temperature stainless steel strips can withstand?

- The maximum temperature that stainless steel strips can typically withstand depends on the specific grade and composition of the stainless steel. However, most stainless steel strips can withstand temperatures ranging from 800 to 1600 degrees Fahrenheit (427 to 871 degrees Celsius) without significant changes to their mechanical properties.

- Q: What are the different types of stainless steel strips?

- There are several different types of stainless steel strips, each with unique properties and applications. Some commonly used types include: 1. Austenitic Stainless Steel: This type is the most commonly used and has excellent corrosion resistance. It is non-magnetic, easily formable, and ideal for applications where high strength and good weldability are required. 2. Ferritic Stainless Steel: Ferritic strips are magnetic and have good corrosion resistance. They are less formable than austenitic stainless steel but have higher strength and are commonly used in automotive exhaust systems, decorative applications, and appliances. 3. Martensitic Stainless Steel: Martensitic strips are known for their high strength and hardness. They have moderate corrosion resistance and are often used in applications that require wear resistance, such as knives, blades, and turbine parts. 4. Duplex Stainless Steel: Duplex stainless steel strips combine the properties of both austenitic and ferritic stainless steels. They have excellent corrosion resistance, high strength, and good weldability. They are commonly used in industries such as oil and gas, chemical processing, and marine applications. 5. Precipitation Hardening Stainless Steel: Precipitation hardening strips have a unique combination of high strength and corrosion resistance. They can be heat treated to achieve even higher strength levels, making them suitable for aerospace and high-performance applications. It is essential to choose the right type of stainless steel strip based on the specific requirements of the application, such as corrosion resistance, strength, formability, and magnetic properties.

- Q: Are stainless steel strips suitable for chemical reactors?

- Certainly, stainless steel strips prove to be a suitable option for chemical reactors. Given their remarkable corrosion resistance properties, stainless steel stands as a favored material for constructing chemical reactors. Its resistance towards a wide range of corrosive substances, such as acids, bases, and salts, makes it highly appropriate for deployment in diverse chemical processes. In terms of structural strength, thermal stability, and durability, stainless steel strips exhibit commendable qualities, rendering them an ideal choice for both the outer shell and internal components of chemical reactors. Moreover, stainless steel's ease of cleaning and maintenance plays a pivotal role in ensuring the integrity and efficiency of the chemical reactor. Taking all these factors into consideration, stainless steel strips undoubtedly emerge as a dependable and suitable material for chemical reactors, delivering the necessary resistance and performance needed to handle a variety of chemical reactions.

- Q: What are the common dimensions of stainless steel strips?

- The common dimensions of stainless steel strips can vary depending on the specific application and industry requirements. However, some commonly available dimensions include thicknesses ranging from 0.1mm to 3mm, widths ranging from 10mm to 500mm, and lengths ranging from a few meters to coils of several hundred meters.

- Q: Is the stainless steel condiment bottle good for rotating or for all holes?

- Many stainless steel grades, different properties, and in the course of its development has gradually formed several categories. According to the structure of the organization, it is divided into four categories: martensitic stainless steel (including precipitation hardening stainless steel), ferritic stainless steel, austenitic stainless steel and austenitic ferrite duplex stainless steel;

- Q: Can stainless steel strips be used in the aerospace landing gear?

- Yes, stainless steel strips can be used in the aerospace landing gear. Stainless steel is a popular material choice for aerospace applications due to its excellent corrosion resistance, high strength, and durability. Landing gear components are exposed to various environmental conditions and stress loads during takeoff, landing, and taxiing, making stainless steel an ideal choice for its ability to withstand these factors. Additionally, stainless steel's resistance to fatigue and impact makes it suitable for withstanding the high loads and shocks experienced during landing and ground operations. Its high strength-to-weight ratio also allows for reduced weight, which is crucial for aerospace applications where weight optimization is a priority. Overall, the use of stainless steel strips in aerospace landing gear provides a reliable and long-lasting solution.

Send your message to us

Hot Rolled Stainless Steel Coil 201 Narrow Strip No.1 Finish

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords