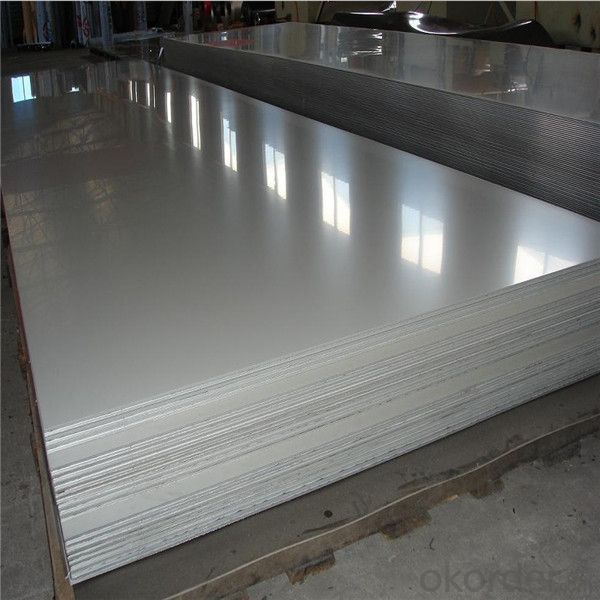

410 430 Color Coating Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

410 430 Color Coating Stainless Steel Sheet

OUR STRENGTH

MANUFACTURER

SPECIALIZING IN PROCESSING 400 SERIES STAINLESS STEEL

WELL-TRAINED AND EXPERIENCED STAFFS

ABLE TO ANSWER ALL YOUR ENQUIRIES IN FLUENT ENGLISH.

SPANISH ENQUIRIES CAN BE WELL UNDESTAND AND REPLIED.

SPECIFICATIONS ( 410 430 Color Coating Stainless Steel Sheet )

Material | Ferrite stainless steel, magnetic. |

Standard | AISI, ASTM, EN, GB, DIN, JIS |

Grade | 409 / 410 / 430 |

Technology | Cold Rolled |

Form | Strips / Coils |

Thickness | 0.17mm - 2.0mm (tolerances ±0.02mm) |

Width | 10.0mm - 850mm (tolerances ±6.00mm) |

Coil ID | Φ500mm-600mm |

Coil OD | Φ2100mm max. |

The sizes or thicknesses of stainless steel coil can be customized, if you need additional information, please don’t hesitate to contact us at any time. | |

CHEMICAL COMPOPSITION ( 410 430 Color Coating Stainless Steel Sheet )

GRADE | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

410 | min. | - | - | - | - | - | 11.50 | - | 0.75 | - |

max. | 0.15 | 1.00 | 1.00 | 0.04 | 0.03 | 13.50 | ||||

430 | min. | - | - | - | - | - | 16.00 | - | - | - |

max. | 0.12 | 1.00 | 1.00 | 0.04 | 0.03 | 18.00 | 0.75 | |||

SERVICE ( 410 430 Color Coating Stainless Steel Sheet )

Processing | Pickling / Straighten / Flatten / Leveling |

Form | Rolling Coils / Cutting Sheets / Stamping Circles |

Edge | Mill Edge / Slitting edge |

Annealed | Full hardness to Deep drawing quality (DDQ) |

Surface | BA - processed with bright heat treatment after cold rolling. |

2B - after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | |

2D – matt finish, best choice for deep drawing | |

Protection | 1. Inter paper available |

2. PVC protecting film available | |

All standard products are supplied without inter paper & PVC film. If needed, please inform. | |

- Q: Are stainless steel sheets heat resistant?

- Indeed, stainless steel sheets exhibit exceptional resistance to heat. Renowned for their ability to withstand high temperatures and corrosion, stainless steel sheets are highly suitable for a wide range of applications. They maintain their structural integrity even under intense heat, without warping, melting, or compromising their integrity. This remarkable heat resistance can be attributed to the presence of chromium in stainless steel, which forms a protective oxide layer on the surface, preventing oxidation and preserving its strength at elevated temperatures. Consequently, stainless steel sheets are extensively utilized in vital industries like manufacturing, construction, automotive, and food processing, where the ability to withstand heat is paramount.

- Q: 304 how can the water stain on the surface of stainless steel plate be formed?

- If you want to scrub the proposal as soon as possible processing, water Jiyue long more difficult to wear off, if it is ferrite, also easy to rust.

- Q: How do you attach stainless steel sheets to a wall?

- To attach stainless steel sheets to a wall, you can use a combination of adhesive and mechanical fasteners. First, ensure that the wall is clean and free from any debris or grease. Apply a strong construction adhesive to the back of the stainless steel sheet, spreading it evenly across the surface. Then, press the sheet firmly against the wall and hold it in place for a few minutes to allow the adhesive to bond. Additionally, use mechanical fasteners such as screws or nails to secure the stainless steel sheet to the wall, placing them along the edges and in the center of the sheet for added support and stability.

- Q: Can stainless steel sheets be used for outdoor sculptures?

- Yes, stainless steel sheets can be used for outdoor sculptures. Stainless steel is highly resistant to corrosion, making it ideal for outdoor applications where the sculpture will be exposed to various weather conditions. It can withstand rain, snow, heat, and UV radiation without losing its strength or deteriorating. Additionally, stainless steel has a sleek and modern appearance which can enhance the visual impact of the sculpture. Its durability and resistance to rust make it a popular choice for outdoor sculptures in parks, gardens, and public spaces.

- Q: What is the magnetic permeability of stainless steel sheets?

- The magnetic permeability of stainless steel sheets can vary depending on the specific alloy and processing conditions. Generally, stainless steel is considered to have a low magnetic permeability, making it a poor conductor of magnetic fields. However, some types of stainless steel, such as ferritic stainless steel, have a higher magnetic permeability compared to other grades like austenitic stainless steel. It is important to note that the magnetic permeability of stainless steel can also be affected by factors such as temperature and the presence of external magnetic fields. Therefore, it is best to consult specific technical data or perform magnetic permeability testing for accurate and detailed information about the magnetic properties of stainless steel sheets.

- Q: What are stainless steel sheets used for?

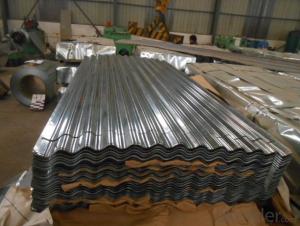

- Stainless steel sheets serve a multitude of purposes in diverse industries. Their outstanding resistance to corrosion, durability, and attractive appearance make them highly sought after in both commercial and residential settings. Within the construction field, these sheets are utilized for roofing, cladding, and facades due to their ability to withstand harsh environmental conditions while providing a contemporary and sleek look. In the automotive industry, they are frequently employed in the construction of car bodies, exhaust systems, and decorative trims. Furthermore, stainless steel sheets find extensive use in the food and beverage sector, where their hygienic qualities make them ideal for kitchen equipment, countertops, and food processing machinery. Additionally, they are widely used in medical equipment, pharmaceuticals, and laboratory settings due to their resistance to corrosion and ease of cleaning. They are also employed in furniture, appliances, signage, and for decorative purposes, as they can be easily customized and molded into various shapes and sizes. All in all, stainless steel sheets are an adaptable material that fulfills a diverse array of requirements in different industries, owing to their strength, durability, and corrosion resistance properties.

- Q: What are the common sizes and thicknesses available for stainless steel sheets?

- Common sizes for stainless steel sheets range from 4 feet by 8 feet to 5 feet by 10 feet, although custom sizes can also be produced. The thicknesses typically vary from 0.4mm to 6mm, with the most commonly used thicknesses being 0.8mm, 1mm, 1.2mm, and 1.5mm.

- Q: Are stainless steel sheets resistant to radiation?

- Yes, stainless steel sheets are generally resistant to radiation. Stainless steel is known for its high resistance to corrosion and oxidation, and it has been used in various industries where radiation exposure is a concern, such as nuclear power plants, medical facilities, and laboratories. Stainless steel's resistance to radiation is due to its composition, which includes chromium, nickel, and other alloying elements that form a protective oxide layer on the surface, preventing radiation from penetrating the material. However, it is important to note that the level of radiation resistance may vary depending on the specific grade and thickness of the stainless steel sheet. Therefore, it is advisable to consult with experts or refer to specific technical specifications when considering the use of stainless steel sheets in radiation-prone environments.

- Q: Are stainless steel sheets good for high-temperature applications?

- Yes, stainless steel sheets are excellent for high-temperature applications due to their unique properties such as high heat resistance, corrosion resistance, and the ability to maintain their strength and integrity even at elevated temperatures.

- Q: What's the difference between galvanized steel and stainless steel?

- Galvanized steel sheet is to prevent the corrosion of steel plate surface, and prolong its service life, the surface of the steel plate is coated with a layer of metal zinc, this kind of zinc coated steel sheet is called galvanized sheet.

Send your message to us

410 430 Color Coating Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords