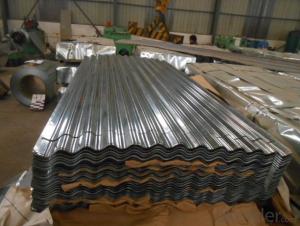

CORRUGATED HOT DIPPED GALVANIZED STEELSHEETS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CORRUGATED HOT DIPPED GALVANIZED STEEL SHEETS

THICKNESS TOLERANCE: (+/-0.01mm)

ZINC COATING: 50g/m2 (+/-10g/m2)

WIDTH: 900mm (0/+5mm; AFTER FORMING)

STANDARD:JIS G 3302, SGCH

SURFACE:REGULAR SPANGLE, CHROMATED, DRY

PACKAGE: 2- 3 TON/PALLET

SPECS: 0.18mm X 900mm X 2000mm

Specifications

1. Zinc coating :60-180g( as required)

2. thickness:0.14-0.80mm

3. width:700-1250mm( 750mm,900mm,1215mm,1250mm,1000mm the most common)

6. surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

7.application: with excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

Package:Standard seaworthy export packing: 3 layers of packing, inside is

kraft paper, water plastic film is in the middle and outside GI steel

sheet to be covered by steel strips with lock.

- Q: What are the different types of surface treatments available for steel sheets?

- There are several types of surface treatments available for steel sheets, including galvanizing, painting, powder coating, and plating. Each treatment offers specific benefits in terms of corrosion resistance, aesthetics, and durability, allowing steel sheets to be customized for various applications and environments.

- Q: What is the difference between a matte and glossy steel sheet?

- The main difference between a matte and glossy steel sheet lies in their surface finish. A matte steel sheet has a dull, non-reflective surface that diffuses light, resulting in a more muted appearance. On the other hand, a glossy steel sheet has a smooth, reflective surface that reflects light, giving it a shiny and polished look.

- Q: Are steel sheets suitable for HVAC ductwork?

- Yes, steel sheets are suitable for HVAC ductwork. Steel is a durable and strong material that can withstand the pressure and temperature changes associated with HVAC systems. It is also resistant to corrosion and leakage, making it an ideal choice for ductwork applications. Additionally, steel sheets can be easily fabricated and installed, ensuring a reliable and efficient HVAC system.

- Q: What is the difference between a pre-annealed and full hard steel sheet?

- A pre-annealed steel sheet is a sheet that has undergone an annealing process to relieve internal stresses and enhance its formability. It is softer and more malleable compared to a full hard steel sheet. On the other hand, a full hard steel sheet has not undergone any additional treatment after being cold-rolled, making it harder and less ductile. It is typically used for applications requiring higher strength and stiffness.

- Q: What is the thickness tolerance for steel sheets?

- The thickness tolerance for steel sheets typically depends on the specific grade and manufacturing process, but it generally ranges from +/- 0.005 to 0.015 inches.

- Q: Can steel sheets be used for electrical conductivity?

- No, steel sheets are not typically used for electrical conductivity as they are not good conductors of electricity.

- Q: What is the typical flexural strength of a steel sheet?

- The typical flexural strength of a steel sheet depends on various factors such as the grade and thickness of the steel. However, it is generally high and can range from 300 to 1,500 megapascals (MPa) or more.

- Q: Can steel sheets be galvanized?

- Yes, steel sheets can be galvanized. Galvanizing is a process of applying a protective zinc coating to steel to prevent corrosion, and it can be done on steel sheets as well.

- Q: Can steel sheets be used for interior wall cladding?

- Yes, steel sheets can be used for interior wall cladding. They can provide a modern and industrial aesthetic, are durable, and can be easily cleaned. However, it is important to consider proper insulation and fireproofing measures when using steel sheets for interior applications.

- Q: What are the different fastening options for steel sheets?

- Depending on the specific application and requirements, there are various fastening options available for steel sheets. Some commonly used fastening options for steel sheets include the following: 1. Screws: Steel sheets can be secured using screws, which are easily accessible and simple to use. Self-tapping screws are commonly employed to fasten steel sheets as they can create their own threads in the material. 2. Bolts and nuts: Bolts and nuts offer a robust and secure fastening choice for steel sheets. They are frequently utilized in situations where adjustability or removability is required. 3. Rivets: Rivets are permanent fasteners commonly used to join two or more steel sheets together. They are often preferred in applications where a watertight or airtight seal is necessary. 4. Welding: Welding is a widely used method for fastening steel sheets. It involves melting the edges of the sheets and joining them together. Welding provides a strong and durable connection but necessitates specialized equipment and expertise. 5. Adhesives: Certain adhesives, such as epoxy or structural adhesives, can be used to bond steel sheets together. Adhesives can create a clean and visually appealing connection, although their strength may vary depending on the specific adhesive used. 6. Clips and clamps: Clips and clamps are frequently employed to secure steel sheets in place. They can be easily installed and removed, making them a popular choice for temporary or adjustable fastening requirements. 7. Magnetic fasteners: Magnetic fasteners, such as magnetic strips or magnets with hooks, can be utilized to attach steel sheets to magnetic surfaces. This offers a convenient and user-friendly fastening option. When selecting a fastening option for steel sheets, it is crucial to consider factors such as strength, durability, ease of installation, and removal. Additionally, the specific requirements of the application, including load-bearing capacity and environmental conditions, should be taken into account to ensure the chosen fastening option is suitable for the intended purpose.

Send your message to us

CORRUGATED HOT DIPPED GALVANIZED STEELSHEETS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords