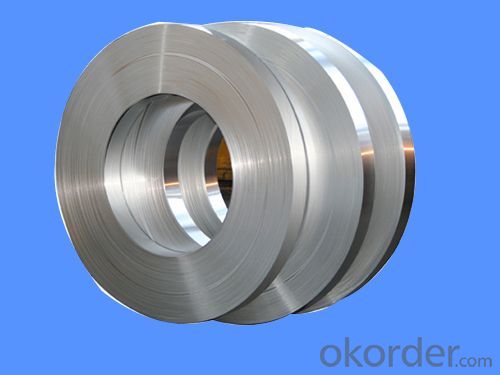

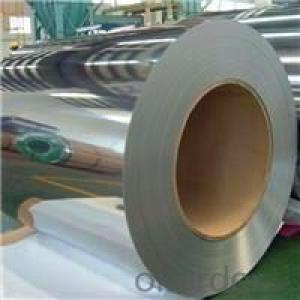

High Quality 201 Coil Stainless Steel Plate/Sheet in Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of goods:Stainless steel plate/Stainless steel coil

Place of Origin:China(Mainland)

Brand Name:TISCO,POSCO,LISCO,BAOSTEEL,JISCO,YONGJIN METAL,EASTERN SPECIAL STEEL,FAR EAST NEW MATERIALect

Model Number:

201/202/301/302/303/303CU/304/304L/304F/304H/304J1/310/310S/314/314L/316/316L/321 //420/430/ 316/316L/316TI

Minimum Order Quantity:20 ton

Packaging Details:Standard export packing or According to customer's requirement

Delivery Time:Within 7-15 Days After Order Confirmed

Payment Terms:T/T, L/C, D/P

Price terms:FOB, CFR, CIF, EXW

Supply Ability:1000 tons per month

Applications:

applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Used for equipments in chemical, coal and the petrochemical industry that request to high corrosion resistance-outdoor machine, architectural materiel, heat-resistant assembly and assemblies that hart to heat treatment. Stainless steel plate also can be made according to the customer's requirements.

Detailed Product Description

Product Name: | Stainless Steel Plates | Thickness: | According to customer's requirement |

Standard: | ASTM, AISI, JIS, EN, DIN, GB | Technology: | Hot Rolled |

Width: | 1000mm,1250mm,1500mm,1800mm,2000mm | Surface: | No.1,2B,No.4,Polishing 8K, Wire Drawing |

- Q: What are the differences between hot-rolled and cold-rolled 111 stainless steel strips?

- The main differences between hot-rolled and cold-rolled 111 stainless steel strips lie in their production processes and resulting characteristics. Hot-rolled stainless steel strips are produced by heating the stainless steel to a high temperature and then passing it through rollers to achieve the desired thickness. This process provides a more malleable and ductile material, allowing for easier shaping and forming. The hot-rolled strips have a rougher surface finish and a scaled oxide layer, which can be removed through additional processing if desired. They also tend to have a larger grain structure, resulting in a less precise and more variable dimensional tolerance. On the other hand, cold-rolled stainless steel strips are produced by further processing the hot-rolled strips through a cold reduction process. This involves passing the hot-rolled strips through a series of rollers at room temperature, which results in a smoother surface finish and a more precise dimensional tolerance. The cold-rolled strips have a finer grain structure and a more uniform thickness, making them ideal for applications where precision and consistency are required. In terms of mechanical properties, hot-rolled stainless steel strips generally exhibit higher yield and tensile strengths compared to cold-rolled strips. This is due to the strain hardening that occurs during the hot-rolling process. However, cold-rolled strips tend to have better surface quality and improved flatness due to the additional processing steps. In summary, hot-rolled stainless steel strips are more malleable and have a rougher surface finish, while cold-rolled strips offer better dimensional precision, surface quality, and flatness. The choice between the two depends on the specific requirements of the application, such as the need for shaping, precision, or surface aesthetics.

- Q: Can stainless steel strips be used in oil and gas industries?

- Yes, stainless steel strips can be used in oil and gas industries. Stainless steel is known for its excellent resistance to corrosion, high strength, and durability, making it an ideal material for various applications in the oil and gas sector. Stainless steel strips can be used for fabricating pipes, tubes, fittings, valves, heat exchangers, and other components that are exposed to harsh operating conditions, including corrosive environments, high temperatures, and high pressures. Additionally, stainless steel offers good weldability and formability, allowing for easy fabrication and installation in oil and gas facilities. Overall, stainless steel strips provide the necessary reliability and performance required in the oil and gas industry.

- Q: How do you measure the hardness of stainless steel strips?

- The hardness of stainless steel strips can be measured using a variety of methods, but the most common technique is the Rockwell hardness test. This test involves applying a specific load to the surface of the steel strip using a diamond or a hardened steel ball. The depth of penetration into the material is then measured, and a hardness value is determined based on the indentation depth. Other methods like the Brinell and Vickers tests can also be used to measure hardness, but the Rockwell test is widely accepted and commonly used in the industry.

- Q: What is the impact strength of stainless steel strips?

- The impact strength of stainless steel strips can vary depending on the specific grade and composition of the stainless steel. Stainless steel is generally known for its excellent strength and durability, and this includes its impact resistance. Stainless steel strips are commonly used in various industries such as construction, automotive, and aerospace, where they are subjected to different types of impact forces. The high strength and toughness of stainless steel allow it to withstand impact and resist deformation, making it suitable for applications that require a material with good impact resistance. However, it is important to note that the impact strength of stainless steel can also be influenced by factors such as the thickness of the strip, the heat treatment applied to the material, and any surface coatings or treatments that may have been applied. Additionally, different grades of stainless steel can have varying impact strengths. To determine the exact impact strength of stainless steel strips, it is necessary to refer to specific material data sheets or conduct laboratory testing according to relevant industry standards. These tests can provide quantitative measurements of impact resistance, such as the ability of the material to withstand a certain level of force without fracturing or breaking.

- Q: What are the recommended cleaning agents for 111 stainless steel strips?

- The recommended cleaning agents for 111 stainless steel strips include mild soaps, non-abrasive cleaners, and specialized stainless steel cleaners. It is important to avoid using harsh chemicals, abrasive scrubbers, and chlorine-based cleaners as they may damage the stainless steel surface.

- Q: Can stainless steel strips be used in food storage containers?

- Indeed, food storage containers can utilize stainless steel strips. Stainless steel emerges as a favored material selection for these containers due to its numerous advantageous qualities. Notably, it exhibits non-reactivity, implying that it does not engage with or modify the taste, appearance, or aroma of the stored food. Moreover, stainless steel boasts corrosion resistance, endowing it with durability and longevity. On top of that, it proves effortless to clean and maintain, while effectively avoiding the retention of unpleasant odors or unsightly stains. These exceptional attributes render stainless steel strips an optimal alternative for food storage containers, guaranteeing the preservation of freshness, safety, and the prevention of contamination.

- Q: Can stainless steel strips be used in the food packaging industry?

- Yes, stainless steel strips can be used in the food packaging industry. Stainless steel is a popular material choice for food packaging due to its excellent corrosion resistance, durability, and hygienic properties. It is non-reactive with food, ensuring that there is no contamination or alteration of the product during packaging. Stainless steel strips are often used to manufacture food packaging containers, trays, and lids as they provide a strong and secure seal, preventing any leakage or spoilage. Additionally, stainless steel is easy to clean and maintain, making it suitable for the strict hygiene standards required in the food industry.

- Q: What is the typical thickness range for stainless steel strips?

- The thickness of stainless steel strips can differ depending on the particular application and industry. Generally, these strips come in a range of thicknesses, starting from 0.0015 inches (0.0381 mm) up to 0.125 inches (3.175 mm). This broad range caters to various purposes, such as employing thin and pliable strips in electronics and precision engineering, or utilizing thicker strips in construction and heavy machinery.

- Q: Stainless steel pan with magnetic or good without magnetic stainless steel pot?

- Stainless steel pot without magnetic is good.In fact, stainless steel is magnetic, and the best stainless steel is austenitic stainless steel, and its magnetic is already weak, and basically no magnetic.

- Q: Are stainless steel strips suitable for appliance handles?

- Yes, stainless steel strips are highly suitable for appliance handles. Stainless steel is known for its durability, corrosion resistance, and sleek appearance, making it an ideal material for handles that are regularly used and exposed to moisture. Moreover, stainless steel can easily be cleaned and maintained, ensuring the longevity and cleanliness of the appliance handles.

Send your message to us

High Quality 201 Coil Stainless Steel Plate/Sheet in Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords