Stainless Steel Coil Cold Rolled 201 with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Stainless Steel Coil Cold Rolled 201 Descriptions

Stainless Steel 201 is a new kind of Austenite stainless steel by used Mn, N replace Ni. The steel has good corrosion resistance and hot / cold processing performance, instead of 304 stainless steel products for used in the not high of corrosive environment, such as indoor, inland city outdoor etc.

2. Main Features of the Stainless Steel Coil Cold Rolled 201

Standard: JIS, SUS, AISI, ASTM

Grade: 201-J1, 201-J4, AISI201, AISI202

Finish: BA, 2B, 8K, NO.3, NO.4, HL

MOQ: 25 Metric Tons

Hardness: Low Hard(190 HV Max); Half Hard(240-280HV); Full Hard(42-60 HRC)

Ship Term: FOB any port, China or CFR Destination port

Delivery Time: 15 to 20 day after the receive the deposit or 100%LC

Payment Terms: TT 30% for deposit, Balance against the copy of B/L, or 100%LC

Packaging: By wooden pallet, wooden case or according to customer's request

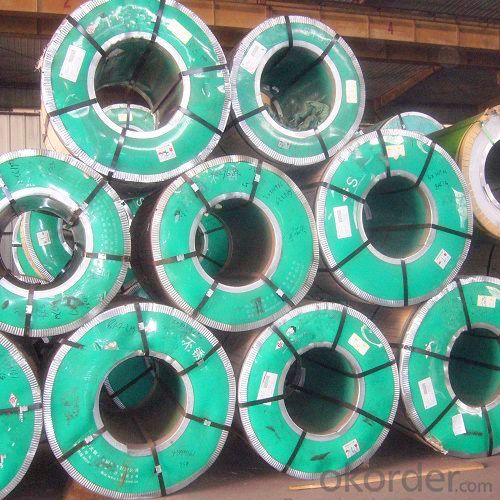

3. Stainless Steel Coil Cold Rolled 201 Images

4. Stainless Steel Coil Cold Rolled 201 Specifications

Mechanical Property Contrast | YS (Mpa) | TS (Mpa) | EL(%) | HV | REMARK |

Stainless Steel 201 | 426 | 880 | 52 | 224 | 1.0t |

Stainless Steel 304 | 285 | 710 | 58 | 165 | 1.0t |

Stainless Steel 200 Series Chemicals Contrast (wt. %) | ||||||||

Chemicals | C | Si | Mn | Cr | Ni | N | Other | |

205 | 0.12-0.25 | ≤0.75 | 14.0-15.0 | 16.5-18.0 | 1.0-1.75 | 0.32-0.4 | ||

JIS, | 201 | ≤0.15 | ≤1.0 | 5.5-7.5 | 16.0-18.0 | 3.5-5.5 | ≤0.25 | - |

201L | ≤0.03 | ≤0.75 | 5.5-7.5 | 16.0-18.0 | 3.5-5.5 | ≤0.25 | - | |

202 | ≤0.15 | ≤1.0 | 7.5-10.0 | 17.0-19.0 | 4.0-6.0 | ≤0.25 | - | |

201LN | ≤0.03 | ≤0.75 | 6.4-7.5 | 16.0-17.5 | 4.0-5.5 | 0.1-0.25 | Cu≤1.0 | |

India | 201-J1 | ≤0.08 | ≤0.75 | 7.0-8.0 | 15.0-17.0 | 4.0-5.0 | ≤0.1 | Cu≤1.5 |

201-J3 | ≤0.08 | ≤0.75 | 9.0-10.5 | 14.0-16.0 | 2.0-3.0 | ≤0.15 | Cu≤2.0 | |

201-J4 | ≤0.10 | ≤0.75 | 8.5-10.0 | 15.0-16.0 | ≤1.2 | ≤0.2 | Cu≤2.0 | |

America | 204 | ≤0.03 | ≤1.0 | 7.0-9.0 | 15.0-17.0 | 1.5-3.0 | 0.15-0.3 | (Cu) |

H400 | ≤0.10 | ≤1.0 | 6.0-9.0 | 17.0-19.5 | ≤3.5 | ≤0.3 | - | |

Japan | YUS130S | 0.09 | 0.5 | 11.0 | 18.0 | 6.5 | 0.35 | - |

NTK S-4 | 0.17 | 0.43 | 14.7 | 17.7 | 1.3 | 0.35 | - | |

NM15M | 0.08 | 0.8 | 14.5 | 17.0 | 4.3 | 0.33 | - | |

Europe America | 219 | ≤0.04 | ≤0.75 | 8.0-10.0 | 19.0-21.5 | 5.5-7.5 | 0.15-0.4 | - |

Cromanite | ≤0.08 | ≤1.0 | 9.5-11.0 | 18.0-20.0 | ≤1.0 | 0.4-0.6 | - | |

201 Surface | Characteristic and Application of Stainless Steel Coil Cold Rolled 201 |

2B | The surface brightness and flatness of 2B is better than 2D then through a special surface treatment to improve its mechanical properties,2B could nearly Satisfy comprehensive uses |

No.4 | Polished with abrasive belt of grit#150#180, have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtub buildings inner and electrical appliances kitchen utensils and food processing. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness like mirror kitchen apparatus, etc. |

8K | The product have excellent brightness and prefer bright can be the mirror. |

5. FAQ of Stainless Steel Coil Cold Rolled 201

Q: Are you factory or trader?

A: We certainly are stainless steel manufacturer and have processing plant.

Q: Can you provide mill test certificate?

A: Yes! Mill test certificate for both hot rolled raw material coils and cold rolled coils are available.

Q: Can you make DDQ (Deep drawing quality)?

A: Yes. Our material has been widely used for producing stainless steel pots and stainless steel sinks, which have strict request for good deep drawing quality.

Q: How to visit your factory?

A: Most of the main cities in the world have flight to Beijing; you can take flight to Beijing first, then we will lead you to our Wuxi mills.

Q: How about your company?

A world class manufacturer & supplier of castings forging in stainless steel, is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 90000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service are available, all according to customer’s requirements.

Q: How to guarantee the quality of the products?

A: We have established the international advanced quality management system,every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do you prevent intergranular corrosion of stainless steel strips?

- To prevent intergranular corrosion of stainless steel strips, several measures can be taken: 1. Use low carbon grades: Intergranular corrosion occurs due to the precipitation of chromium carbides at grain boundaries when stainless steel is exposed to high temperatures for an extended period. By using low carbon grades, such as Type 304L or Type 316L, the carbon content is minimized, reducing the formation of carbides and thus preventing intergranular corrosion. 2. Heat treatment: After welding or other high-temperature processes, stainless steel strips should be properly heat-treated to restore the corrosion resistance. This process, known as solution annealing or sensitization treatment, involves heating the material to a specific temperature range and then rapidly cooling it to dissolve the carbides and prevent their precipitation at grain boundaries. 3. Pickling and passivation: Pickling involves the use of an acid solution to remove any impurities or contaminants from the stainless steel surface, while passivation creates a protective oxide layer on the surface to enhance corrosion resistance. Regular pickling and passivation treatments can help prevent intergranular corrosion by removing any potential corrosion sites and improving the overall surface condition. 4. Avoid exposure to high temperatures: Stainless steel strips should be protected from prolonged exposure to high temperatures, as this can lead to sensitization and subsequent intergranular corrosion. If unavoidable, the use of thermal barriers, such as insulation or coatings, can help minimize the direct contact between the stainless steel and the elevated temperatures. 5. Use corrosion inhibitors: Applying corrosion inhibitors, such as specialized coatings or inhibitors in the working environment, can provide an additional layer of protection against intergranular corrosion. These inhibitors work by forming a protective film on the stainless steel surface, preventing the attack of corrosive agents and reducing the risk of intergranular corrosion. Overall, preventing intergranular corrosion of stainless steel strips involves a combination of material selection, proper heat treatment, surface treatment, and protection measures. By implementing these preventive measures, the risk of intergranular corrosion can be significantly reduced, ensuring the long-term durability and performance of stainless steel strips.

- Q: Can stainless steel strips be heat treated?

- Stainless steel strips are indeed capable of undergoing heat treatment. This particular process serves to modify the physical and mechanical characteristics of metals, including stainless steel. The purpose behind heat treating stainless steel strips can encompass a range of objectives, such as enhancing hardness, strengthening, improving resistance to corrosion, or adjusting ductility. The heat treatment process typically involves subjecting the stainless steel strips to a specific temperature and subsequently employing a controlled cooling technique. Depending on the desired properties, various heat treatment methods can be utilized, such as annealing, quenching, tempering, or solution treatment. As a consequence of heat treating stainless steel strips, their performance can be significantly enhanced, leading to a broadened scope of applications across diverse industries, including automotive, aerospace, construction, and manufacturing.

- Q: Can stainless steel strips be used in defense applications?

- Yes, stainless steel strips can be used in defense applications. Stainless steel is known for its durability, corrosion resistance, and strength, making it suitable for various defense purposes such as armor plating, weapon components, and military vehicles. Its ability to withstand harsh environments and resist impact makes it a reliable choice in defense applications.

- Q: How do stainless steel strips compare to aluminum strips in terms of strength?

- Stainless steel strips are generally stronger than aluminum strips.

- Q: Are stainless steel strips resistant to embrittlement?

- Yes, stainless steel strips are generally resistant to embrittlement. Embrittlement refers to the loss of ductility and the development of brittleness in a material, which can lead to cracking or fracturing under stress. Stainless steel is an alloy that contains a minimum of 10.5% chromium, which forms a protective oxide layer on the surface of the material. This oxide layer provides excellent corrosion resistance and also helps to prevent embrittlement. Additionally, stainless steel contains other alloying elements such as nickel and molybdenum, which further enhance its resistance to embrittlement. These alloying elements help to maintain the structure and integrity of the material, even under extreme conditions or exposure to high temperatures. However, it is important to note that certain factors can still lead to embrittlement in stainless steel strips. For example, exposure to very high temperatures (above the recommended operating range) or prolonged exposure to certain chemicals can cause embrittlement. Additionally, improper heat treatment or welding processes can also affect the material's resistance to embrittlement. Therefore, while stainless steel strips are generally resistant to embrittlement, it is crucial to consider the specific operating conditions and ensure proper handling, heat treatment, and maintenance to maintain the material's integrity.

- Q: Can stainless steel strips be used in the production of water treatment equipment?

- Yes, stainless steel strips can be used in the production of water treatment equipment. Stainless steel is known for its corrosion resistance, durability, and hygienic properties, making it suitable for use in water treatment applications where the material may come into contact with water and chemicals. It can be used to fabricate various components of water treatment equipment such as tanks, piping, valves, and filters, providing a reliable and long-lasting solution.

- Q: Can stainless steel strips be used for solar panel frames?

- Solar panel frames can indeed utilize stainless steel strips. The use of stainless steel is renowned due to its remarkable resistance to corrosion and its durable nature, rendering it an ideal substance for outdoor purposes like solar panels. By employing stainless steel frames, the solar panels are provided with structural reinforcement, guaranteeing their stability and security. Moreover, stainless steel possesses a lightweight quality, facilitating the effortless installation and transportation of the panels. Its capability to endure severe weather conditions, encompassing rain, snow, and UV radiation, establishes stainless steel as a dependable selection for solar panel frames.

- Q: What is the yield strength of stainless steel strips?

- The yield strength of stainless steel strips can vary depending on the specific grade and thickness of the material. Generally, stainless steel strips have a higher yield strength compared to other types of steel due to their composition, which includes a minimum of 10.5% chromium. However, the yield strength can range from around 200 megapascals (MPa) for low-grade stainless steel strips to over 1000 MPa for high-grade stainless steel strips. It is important to consult the manufacturer's specifications or perform material testing to determine the exact yield strength of a specific stainless steel strip.

- Q: What is the typical thickness range of stainless steel strips?

- The typical thickness range of stainless steel strips can vary depending on the specific application and industry requirements. However, in general, stainless steel strips are available in thicknesses ranging from 0.1mm to 3mm. Thinner strips, such as those with a thickness below 0.5mm, are commonly used in industries like electronics, automotive, and medical devices. On the other hand, thicker strips, typically in the range of 1mm to 3mm, are utilized in heavy-duty applications like construction, oil and gas, and industrial machinery. It is important to note that these thickness ranges are not exhaustive and can be customized based on individual project needs.

- Q: Are stainless steel strips resistant to scaling and oxidation?

- Yes, stainless steel strips are resistant to scaling and oxidation. This is due to the high levels of chromium present in stainless steel, which forms a protective layer on the surface of the material. This layer, known as a passive film, prevents the steel from reacting with oxygen in the air and helps to prevent corrosion and scaling. Additionally, stainless steel also contains other alloying elements such as nickel and molybdenum, which further enhance its resistance to oxidation and scaling. Therefore, stainless steel strips are widely used in various industries where corrosion resistance is crucial, such as in the manufacturing of kitchen appliances, automotive parts, and chemical processing equipment.

Send your message to us

Stainless Steel Coil Cold Rolled 201 with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords