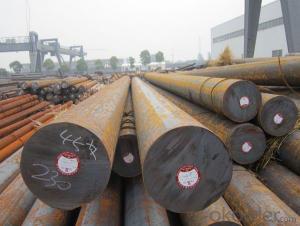

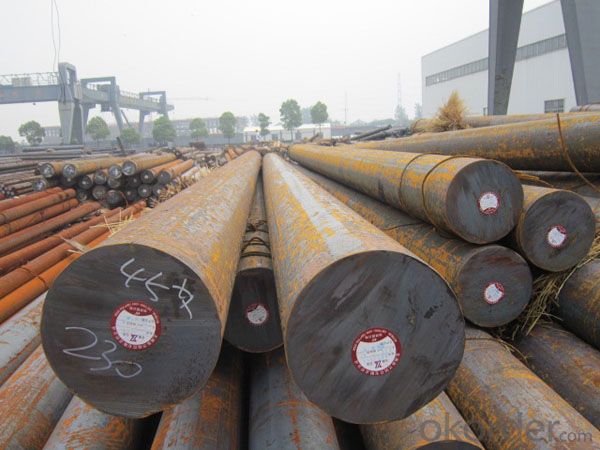

Wholesale AISI 420 Medium Carbon Special Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

1.ISO9001:2008 certificate

2.Competive price and Best quality

3.On-time delivery

Chemical Composition(GB)%

| C | Si | Mn | Cr | P | S |

| 0.4 | 0.5 | 0.7 | 13 | ≤0.030 | ≤0.030 |

Standard

| GB | ASTM | DIN | JIS |

| 4Cr13 | 4.2 | 1.2083 | 420J2 |

Available Size

| Rolled plate | 12-120mm*720mm*6000mm | ||

| Module | 130-400mm*1000mm*6000mm | ||

Heat Treatment

| Processing | Temperature ℃ | Hardness |

| Anneal | 750-800 | ≤235HB |

| Quenching | 1050-1100 | ≥50HRC |

| Tempering | 200-300 | ≥50HRC |

Characterstics

| 1.High corrosion resistance and mirror performance | |||||

| 2.Higher strength and abrasion resistance |

Applications:Suitable for precise dies with super mirror performance and abrasion resistance,camera components,optical lens 420J2 STEEL

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

4, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

We provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the main applications of special steel in the chemical processing industry?

- Special steel is widely used in the chemical processing industry due to its unique properties and capabilities. Some of the main applications of special steel in this industry include the manufacturing of storage tanks, pipelines, and reactors. Special steel is resistant to corrosion, high temperatures, and chemical reactions, making it ideal for handling and storing various chemicals and substances. Additionally, special steel is also utilized in the construction of equipment used in the separation, purification, and filtration processes in chemical plants. Overall, the main applications of special steel in the chemical processing industry revolve around its durability, resistance to corrosion, and ability to withstand harsh chemical environments.

- Q: What are the different nitriding techniques used for special steel?

- There are several nitriding techniques used for special steel, including gas nitriding, salt bath nitriding, plasma nitriding, and ion nitriding. Each technique involves introducing nitrogen into the surface of the steel to improve its hardness, wear resistance, and corrosion resistance. Gas nitriding involves exposing the steel to ammonia gas at high temperatures, while salt bath nitriding immerses the steel in a bath of molten salts containing nitrogen. Plasma nitriding and ion nitriding both use electrical discharges to ionize nitrogen gas and accelerate it towards the steel surface. These techniques offer different levels of control over the nitriding process and can be tailored to meet specific requirements for different types of special steel applications.

- Q: Can special steel be used in the electronics industry?

- Yes, special steel can be used in the electronics industry. It is commonly used for various components such as connectors, springs, and contacts due to its high strength, corrosion resistance, and electrical conductivity properties.

- Q: How is mold steel used in the production of plastic injection molds?

- Mold steel is used in the production of plastic injection molds as it provides the necessary hardness, durability, and heat resistance required for the molding process. It ensures the molds can withstand the high pressures and temperatures involved in plastic injection molding, allowing for the precise and efficient production of plastic parts.

- Q: What are the different methods for annealing special steel?

- Special steel can be annealed using various methods, each with its own objectives and outcomes. Some commonly employed techniques include the following: 1. Full annealing: To achieve maximum softness and enhanced ductility, the steel is heated above its critical temperature and held there for a specific duration. It is then gradually cooled to room temperature. This process facilitates easier machining and manipulation of the steel. 2. Isothermal annealing: After heating the steel above its critical temperature, it is promptly transferred to a furnace or chamber where it is maintained at a constant temperature. This controlled cooling results in a uniform and fine-grained microstructure. Isothermal annealing is particularly beneficial for complex-shaped parts, minimizing distortion and improving dimensional stability. 3. Spheroidize annealing: This technique is commonly employed for high-carbon steels. The steel is heated to a temperature slightly below its critical temperature and kept there for an extended period. This encourages the formation of spheroidized carbides, enhancing machinability and reducing brittleness. 4. Process annealing: Cold-worked steel undergoes this method to alleviate internal stresses and decrease hardness. The steel is heated below its critical temperature and then cooled in still air. Process annealing restores ductility and enhances formability. 5. Stress-relief annealing: Residual stresses resulting from welding or machining can be relieved using this method. The steel is heated below its critical temperature and then slowly cooled. Stress-relief annealing minimizes distortion and prevents cracking. It is crucial to consider factors such as steel composition, desired mechanical properties, and intended application when selecting the appropriate annealing method for special steel.

- Q: What are the challenges in working with special steel?

- Working with special steel presents several unique challenges compared to working with regular steel. Here are some of the main challenges one may encounter when working with special steel: 1. High cost: Special steels often have higher production costs due to their unique composition and properties. The raw materials used in their production may be rare or require complex manufacturing processes, leading to increased costs. 2. Limited availability: Special steels are not as widely available as regular steels, making it more challenging to source them. This limited availability can lead to longer lead times and potentially higher costs when trying to procure the necessary materials. 3. Complexity in machining: Special steels can be difficult to machine due to their high hardness or toughness. Their unique properties may cause excessive tool wear, leading to increased machining time and costs. Specialized cutting tools and machining techniques may be required to overcome these challenges. 4. Heat treatment requirements: Special steels often require precise and specific heat treatment processes to achieve the desired mechanical properties. The complexity of heat treatment can be a challenge, as it requires careful control of temperature, time, and cooling rates. Improper heat treatment can lead to inconsistent material properties or even material failure. 5. Weldability issues: Some special steels may have poor weldability compared to regular steels. They may be prone to cracking or require preheating and post-weld heat treatment to ensure proper joint integrity. This can add complexity and cost to welding processes. 6. Corrosion resistance: While special steels may possess excellent mechanical properties, they can sometimes be more susceptible to corrosion compared to regular steels. This requires additional measures to protect the steel from corrosion, such as applying protective coatings or using corrosion-resistant alloys. 7. Knowledge and expertise: Working with special steels often demands a higher level of technical knowledge and expertise. The unique properties and characteristics of these materials require a deep understanding of their behavior and how to effectively work with them. This may require specialized training or collaboration with experts in the field. Despite these challenges, working with special steel can also offer various benefits, such as superior strength, durability, and performance in specific applications. By understanding and addressing these challenges, engineers and manufacturers can harness the unique properties of special steel to develop innovative and high-quality products.

- Q: How is special steel used in the production of turbine shafts?

- Special steel is used in the production of turbine shafts due to its high strength, durability, and resistance to corrosion and fatigue. The unique properties of special steel make it ideal for withstanding the extreme conditions and loads experienced by turbine shafts during operation, ensuring efficient and reliable power generation.

- Q: What are the potential health hazards associated with working with special steel?

- There are potential health risks when working with special steel due to the materials and processes involved. Some of the main health hazards associated with this work include: 1. Inhaling harmful fumes: Special steels often contain various alloys and elements, such as chromium, nickel, and manganese. These can release toxic fumes when heated or welded. Prolonged exposure to these fumes can cause respiratory issues like bronchitis, asthma, or even lung cancer. 2. Irritation of the skin and eyes: Steelworking involves handling sharp edges, cutting tools, and abrasive materials, which can cause cuts, scratches, or puncture wounds. If not treated properly, these injuries can become infected or lead to more serious conditions. Additionally, contact with certain alloys in special steel can irritate the skin or cause allergic reactions. It's important to wear eye protection to prevent injuries from debris or sparks. 3. Hearing loss caused by noise: Steel manufacturing processes often involve heavy machinery, which creates high levels of noise. Prolonged exposure to this noise can result in permanent hearing loss or other auditory issues. Using appropriate hearing protection, like earmuffs or earplugs, can help reduce the risk. 4. Hazards related to ergonomics: Steelworking often requires repetitive movements, heavy lifting, or uncomfortable postures. This can lead to musculoskeletal disorders such as back pain, carpal tunnel syndrome, or tendonitis. Employers should implement proper ergonomic practices, such as adjustable workstations, lifting aids, and regular breaks, to prevent these hazards. 5. Thermal hazards: Special steel manufacturing processes involve high temperatures, such as welding or forging. Without proper protective clothing or equipment, this can result in burns. Exposure to extreme heat can also lead to heat-related illnesses like heat exhaustion or heat stroke. Adequate training, appropriate personal protective equipment (PPE), and regular breaks in cooler areas can help reduce these risks. To protect workers from these potential health hazards, employers should follow proper safety protocols. This includes providing employee training, ensuring the use of personal protective equipment, conducting regular health monitoring, and maintaining a clean and well-ventilated work environment. It is important to strictly adhere to occupational health and safety regulations in order to minimize the risks involved in working with special steel.

- Q: What properties make special steel unique?

- Special steel, also known as alloy steel, possesses unique properties that set it apart from other types of steel. Firstly, special steel is distinguished by its exceptional strength and hardness. It is engineered to have a high resistance to deformation, making it suitable for applications that require robust materials. Whether in construction, automotive, or aerospace industries, special steel provides the necessary durability and reliability. Another remarkable property of special steel is its superior corrosion resistance. By incorporating certain alloying elements such as chromium, nickel, or molybdenum, this type of steel becomes highly resistant to rust and other forms of corrosion. As a result, special steel is often used in marine environments, chemical plants, and oil and gas industries where exposure to harsh conditions is prevalent. Furthermore, special steel demonstrates excellent heat resistance. It can withstand high temperatures without losing its strength or structure, making it suitable for applications in extreme heat environments, such as power generation or furnace components. This property allows special steel to be utilized in critical situations where other materials may fail or degrade. Special steel is also known for its versatility and adaptability. With various alloying elements and heat treatment processes, it can be tailored to meet specific requirements of different industries. This flexibility makes it possible to create specialized alloys with unique properties, such as improved machinability, wear resistance, or enhanced magnetic properties, catering to a wide range of applications. In conclusion, the properties that make special steel unique are its exceptional strength and hardness, superior corrosion resistance, excellent heat resistance, and its versatility in being tailored to specific requirements. These properties make special steel an invaluable material in numerous industries, enabling the development of innovative and reliable products.

- Q: What are the different applications of stainless special steel?

- Stainless special steel finds various applications in industries like construction, automotive, aerospace, and medical. It is commonly used in the production of surgical instruments, chemical processing equipment, heat exchangers, and food processing machinery. Its corrosion resistance, strength, and ability to withstand high temperatures make it an ideal choice for applications where durability and hygiene are essential.

Send your message to us

Wholesale AISI 420 Medium Carbon Special Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords