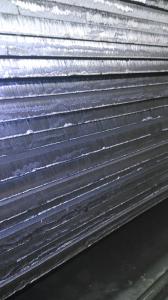

Prime Flat Bars Slitted with Variety Size and Thichness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000T m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Prime Flat Bars Slitted with Variety Size and Thichness at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Prime Flat Bars Slitted with Variety Size and Thichness are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Prime Flat Bars Slitted with Variety Size and Thichness are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: slited

Slitting precision (width) : 0.5 mm or less

Raw material: Q235B, Q345B, Q235-1 b

crosscutting precision (length) : 2 mm or less

Processing: the thickness of 2.0-16 mm;

Shear length: 2000 mm above

Wide degree: 15-1250 - mm;

Leveling precision: 1-2 MM square

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How many tons of steel products could be loaded in containers?

A2: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Q3: what is the difference between actual weight and theoretical weight?

A3: All the section steel has two weights: actual weight and theoretical weight. Actual weight is the weighing out when the product delivered from the mill. Theoretical weight is calculated by pieces. The invoice can be based on each of them as your request.

Images:

- Q: How do steel flat bars compare to wood for certain applications?

- Steel flat bars have several advantages over wood for certain applications. Firstly, steel flat bars are much stronger and more durable than wood, making them ideal for heavy-duty applications that require a high level of strength and stability. Additionally, steel flat bars are not susceptible to rot, decay, or insect damage like wood, making them a more long-lasting option. Moreover, steel flat bars are fire-resistant, making them safer in environments where fire hazards are a concern. Finally, steel flat bars can be easily shaped and manipulated, allowing for greater design flexibility compared to wood. Overall, steel flat bars offer superior strength, durability, and safety benefits, making them a preferred choice for many applications.

- Q: What are the different types of surface coatings for steel flat bars?

- There are several types of surface coatings available for steel flat bars, including galvanized coatings, powder coatings, epoxy coatings, and painted coatings. These coatings can provide protection against corrosion, enhance durability, improve aesthetics, and offer various levels of resistance to chemicals and abrasion. The choice of coating depends on the specific requirements and intended use of the steel flat bars.

- Q: Are steel flat bars suitable for machine frames?

- Yes, steel flat bars are generally suitable for machine frames. Steel is known for its strength, durability, and resistance to wear and tear, making it a popular choice for machine frames in various industries. Steel flat bars are particularly useful for constructing machine frames due to their flat and rectangular shape, which allows for easy welding and assembly. Additionally, steel flat bars offer excellent stability and rigidity, ensuring that the machine frame can support the weight and vibrations generated during machine operation. Overall, steel flat bars provide a solid and reliable foundation for machine frames, making them a suitable choice for this application.

- Q: What is the difference between hot-rolled and extruded steel flat bars?

- Hot-rolled and extruded steel flat bars find common usage across various industries, yet they vary in terms of their manufacturing methods and resultant properties. Hot-rolled flat bars are manufactured by subjecting a steel billet or slab to temperatures surpassing its recrystallization point. Subsequently, it is rolled through a series of rollers to attain the desired shape and dimensions. This process yields a scaled surface due to the exposure to high temperatures. Renowned for their strength and toughness, hot-rolled steel flat bars are ideal for load-bearing applications like construction and infrastructure projects. Additionally, they possess a coarser surface texture when compared to extruded steel flat bars. In contrast, extruded steel flat bars are formed by coercing a heated steel billet through a die, shaping it accordingly. The extrusion process ensures a smooth and uniform surface finish, as the steel is not subjected to the same elevated temperatures as in hot rolling. These extruded steel flat bars are acclaimed for their precise dimensions and uniform cross-sectional shape, making them well-suited for applications necessitating tight tolerances, such as manufacturing machinery and architectural components. Moreover, they exhibit a finer surface finish compared to their hot-rolled counterparts. To summarize, the primary distinction between hot-rolled and extruded steel flat bars emerges from their manufacturing procedures and resultant properties. Hot-rolled bars possess robustness and toughness, accompanied by a rougher surface texture. Conversely, extruded bars offer precise dimensions alongside a smoother surface finish, rendering them suitable for applications that require stringent tolerances.

- Q: How do you prevent warping of steel flat bars during fabrication?

- To prevent warping of steel flat bars during fabrication, several measures can be taken. Firstly, it is crucial to ensure that the bars are stored and handled properly before fabrication, as any distortion or bending can lead to warping. Additionally, maintaining proper temperature and humidity conditions in the fabrication area is essential, as high temperatures can cause the bars to expand unevenly and result in warping. Adequate cooling techniques, such as quenching or controlled cooling, can also be employed to minimize the risk of warping. Lastly, using appropriate welding techniques and evenly distributing heat during the fabrication process can help prevent warping of steel flat bars.

- Q: Are steel flat bars resistant to fire?

- Generally, steel flat bars are resistant to fire. Steel, being a non-combustible material, does not burn or aid in the spread of fire. Due to its high melting point and excellent heat resistance, steel is highly resistant to fire. As a result, steel flat bars are commonly used in construction, manufacturing, and industrial settings where fire resistance is necessary. However, it is important to remember that while steel itself is fire-resistant, other materials attached to or surrounding the steel bars may not be. Therefore, it is crucial to consider the entire system and ensure that all components are fire-resistant to provide maximum fire protection.

- Q: Can steel flat bars be an alternative to wood in construction?

- Yes, steel flat bars can be a viable alternative to wood in construction. Steel flat bars offer several advantages over wood, making them a popular choice for various applications in the construction industry. Firstly, steel flat bars are extremely strong and durable, providing a higher level of structural integrity compared to wood. They can withstand heavy loads and resist bending or warping, making them ideal for supporting large structures or carrying heavy loads. This strength also translates to increased safety and longevity, as steel is less prone to damage from weather, pests, or decay. Additionally, steel flat bars are highly versatile and can be easily customized to suit specific construction requirements. They can be cut, welded, and bent into various shapes or sizes, allowing for greater design flexibility. This versatility makes steel flat bars suitable for a wide range of structural applications, such as beams, columns, braces, or even as reinforcements in concrete structures. Furthermore, steel is a sustainable and environmentally friendly material. It can be recycled indefinitely without losing its properties, reducing the need for new raw materials and minimizing waste. In contrast, wood is a limited resource that requires deforestation and can contribute to environmental degradation if not sustainably sourced. Lastly, steel is fire-resistant, providing enhanced safety in construction. Unlike wood, which is highly combustible, steel flat bars have a high melting point and do not contribute to the spread of fire. This fire resistance can be crucial in preventing the rapid spread of flames and ensuring the integrity of the structure. While steel flat bars have numerous advantages as an alternative to wood in construction, it is essential to consider factors such as cost, aesthetics, and local building regulations. Additionally, certain applications may still require the use of wood due to specific characteristics or design preferences. Therefore, a comprehensive evaluation of the project's requirements and constraints is necessary to determine whether steel flat bars are a suitable alternative to wood in a particular construction scenario.

- Q: Are steel flat bars suitable for machine parts?

- Yes, steel flat bars are suitable for machine parts. Steel is a durable and strong material that is commonly used in the manufacturing industry for various applications. Steel flat bars provide a flat and uniform surface, making them ideal for machine parts such as brackets, supports, frames, and guides. They can withstand heavy loads, resist wear and tear, and provide stability and structural integrity to the machine. Additionally, steel flat bars can be easily machined, welded, and shaped to fit specific requirements, allowing for customization and versatility in machine part design. Overall, steel flat bars are a reliable and widely used choice for machine parts due to their strength, durability, and ease of use.

- Q: Can steel flat bars be used in the manufacturing of conveyor systems?

- Yes, steel flat bars can be used in the manufacturing of conveyor systems. Steel flat bars are commonly used as support structures or frame components in conveyor systems due to their strength, durability, and versatility. They can be easily welded or bolted together to create custom-sized frames or supports that can withstand heavy loads and continuous use. Additionally, steel flat bars can be shaped or cut to fit specific conveyor designs, making them an ideal choice for conveyor system manufacturing.

- Q: What is the thickness tolerance for steel flat bars?

- The thickness tolerance for steel flat bars can vary depending on the specific grade and manufacturing standard being followed. However, in general, the industry standard tolerance for steel flat bars is typically +/- 0.005 inches (0.127mm) to +/- 0.010 inches (0.254mm). This means that the actual thickness of a steel flat bar can deviate within this range from the specified nominal thickness. It is important to consult the relevant manufacturing standard or supplier specifications for the specific tolerance requirements of the steel flat bars being considered.

Send your message to us

Prime Flat Bars Slitted with Variety Size and Thichness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000T m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords