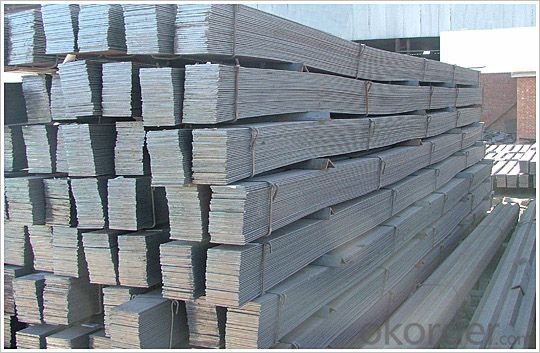

Flat Bar High Quality Steel Flat Bar,Flat Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Seaworthy export packed |

| Delivery Detail: | 20-25 days |

Specifications

High Quality steel flat bar,flat steel,flat bar

1. Q235,Q345,SS400,ASTM A36,S235JR,S275JR

2. USD 495-516/Ton

3. Free Sample

flat steel,Steel Flat Bar, Galvanized Flat Bar,SS400 flat steel,galvanized flat steel

typical size range: | 10*3 – 300*25mm 6 – 12M Long (special lengths can also be provided) |

Available specifications: | EN 10025 GB/T704-2004 JIS G3101 |

Steel grades: | S235JR, S355JR, Q235B, Q345B, SS400 |

Application of Flat Bar

Flat Bar is used for general fabrication, making structures and frames. Mild Steel Flat Bar can be easily cut and drilled, and is particularly suited to welding. Examples of its use include furniture making, machinery manufacturing, shipbuilding, railway spare parts, iron towers, steel structures, and boilers.

1. What grades and standards of steel are used for your production?

Our grades could meet most of customers demand, such as ASTM, GB, JIS, EN etc…Specific grades include commercial quality, low carbon; high carbon and high strength select low alloys.

2. What type of finishes is your product produced in?

We produce steel product in a wide variety of finishes, including hot-rolled black, hot-rolled pickled & oiled, cold-rolled, aluminized, and hot dipped galvanized. If you have a specific finish that is required, please contact us for additional information.

3. What is your order minimum?

As an experienced steel materials manufacturer, we sell in one full container and combination container. Although the total weight on an order will vary due to the type and size, a typical full container load or less container load order will be approximately 15-25 tons.

4. What could we get if we build up relationship with you company?

Frankly, you get competitive price, good quality materials and considerable payment term. Our experienced team will offer you full service from order confirmation to goods arrival your warehouse. You have nothing to worry about during the process.

- Q: What are the common welding methods used for steel flat bars?

- The common welding methods used for steel flat bars are MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and stick welding (Shielded Metal Arc Welding).

- Q: What are the different methods of surface coloring for steel flat bars?

- Steel flat bars can be surface colored in various ways, each offering unique benefits and applications. Some commonly used methods include: 1. Hot-dip galvanizing: By immersing the steel flat bar in molten zinc, a protective layer forms on the surface. This method excels in outdoor or high-moisture environments, providing excellent corrosion resistance. 2. Powder coating: Here, a dry powder paint is applied to the steel flat bar's surface and then cured with heat. Powder coating offers a wide range of colors, exceptional durability, and resistance to chipping, scratching, and fading. 3. Electroplating: Using an electric current, a thin layer of metal like chrome or nickel is deposited onto the steel flat bar's surface. This method enhances appearance and provides corrosion resistance. 4. Paint coating: The conventional approach of directly applying paint to the steel flat bar's surface is still popular. It offers a wide variety of colors and finishes, though durability and corrosion resistance may not match other methods. 5. Chemical coloring: By using chemicals, a controlled oxidation process is initiated on the steel flat bar's surface, resulting in various colors and shades. Chemical coloring enhances appearance and boosts corrosion resistance. 6. Anodizing: Primarily used for aluminum but applicable to steel flat bars, anodizing involves creating an oxide layer through electrochemical means. This process enhances corrosion resistance and allows for color addition through dyes. Each method has its own advantages and considerations, including cost, environmental impact, durability, and aesthetic appeal. The choice of surface coloring method depends on specific requirements, such as desired appearance, corrosion resistance level, and budget constraints.

- Q: Can steel flat bars be used for elevator shafts or doors?

- Yes, steel flat bars can be used for elevator shafts or doors. Steel flat bars are commonly used in construction and fabrication projects due to their strength and durability. Elevator shafts and doors require materials that can withstand heavy loads, provide structural integrity, and ensure safety for passengers. Steel flat bars possess these qualities and are often used in the construction of elevator shafts and doors. They can be fabricated and welded to create the necessary framework and provide the necessary support for elevator systems. Additionally, steel flat bars can be coated or treated to enhance their corrosion resistance, making them suitable for both interior and exterior elevator applications.

- Q: What's the difference between stainless steel flat bar 304 and 316?

- 316 stainless steel flat type is 316, the material is stainless steel. The stainless steel should be a bundle of delivery, the bundle passes, bundle length should be specified. Stainless steel flat is generally naked, delivery, transportation and storage are required to pay attention to moisture.

- Q: What is the difference between steel band and steel ring? The steel strip is flat steel and the steel ring is made of steel. Am I right?

- A steel strip is also a coil, usually a narrow strip, also known as a steel strip. The volume is relatively wide. In addition, flat steel is usually hot-rolled out of long strip steel, fixed length 5 and 5.5,6 meters range, steel coil is Kaiping Chang 12501500, length 2.5 meters, 4 meters, 6 meters, ranging from steel plate

- Q: Can steel flat bars be used for making signage?

- Yes, steel flat bars can be used for making signage. They are a durable material that can withstand outdoor conditions and provide a sturdy base for mounting signs.

- Q: Are steel flat bars available in different edge treatments?

- Yes, steel flat bars are available in different edge treatments. Some common edge treatments for steel flat bars include squared edges, rounded edges, beveled edges, and chamfered edges. These edge treatments serve various purposes and can be chosen based on the specific application or aesthetic preference. For example, squared edges provide a clean and sharp look, while rounded edges offer a smoother and safer finish. Beveled edges are often used for decorative purposes or to reduce the risk of sharp corners, and chamfered edges can help with easier installation or alignment. The availability of different edge treatments allows for greater versatility and customization when using steel flat bars in various projects.

- Q: Can steel flat bars be cut to specific lengths?

- Yes, steel flat bars can be cut to specific lengths. Steel flat bars can be easily cut using various tools such as hacksaws, angle grinders, or even specialized metal cutting machines. These tools allow for precise and accurate cutting of steel flat bars to any desired length, ensuring that they fit perfectly for any intended application. It is important to use appropriate safety measures and techniques when cutting steel bars to avoid any accidents or injuries.

- Q: How do steel flat bars compare to rubber flat bars?

- Steel flat bars and rubber flat bars have different properties and uses, making them suitable for different applications. Steel flat bars are typically made from high-quality steel and are known for their strength and durability. They have excellent load-bearing capacity and can withstand heavy weights and pressure. Steel flat bars are commonly used in construction, manufacturing, and engineering industries where strength and stability are essential. They are also resistant to corrosion, making them suitable for outdoor applications. On the other hand, rubber flat bars are made from synthetic rubber compounds and are known for their flexibility and shock-absorbing properties. They are primarily used in applications where vibration reduction, impact resistance, or cushioning is required. Rubber flat bars are commonly used in industries such as automotive, machinery, and transportation, where they can absorb impacts and reduce noise and vibrations. In terms of cost, steel flat bars are generally more expensive than rubber flat bars due to the higher cost of steel production. However, steel flat bars are also more durable and have a longer lifespan, making them a cost-effective choice in the long run. Overall, the choice between steel flat bars and rubber flat bars depends on the specific requirements of the application. If strength, durability, and load-bearing capacity are crucial, steel flat bars are the preferred choice. However, if flexibility, shock absorption, and vibration reduction are essential, rubber flat bars are the better option.

- Q: Are steel flat bars susceptible to rusting?

- Steel flat bars can rust because they are made mostly of iron, a metal that easily reacts with oxygen in the presence of moisture to create rust, also known as iron oxide. Therefore, if steel flat bars are exposed to moisture and oxygen, they can corrode and acquire rust over time. To minimize the chance of rusting, it is crucial to apply protective coatings or regularly clean and maintain the steel bars.

Send your message to us

Flat Bar High Quality Steel Flat Bar,Flat Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords