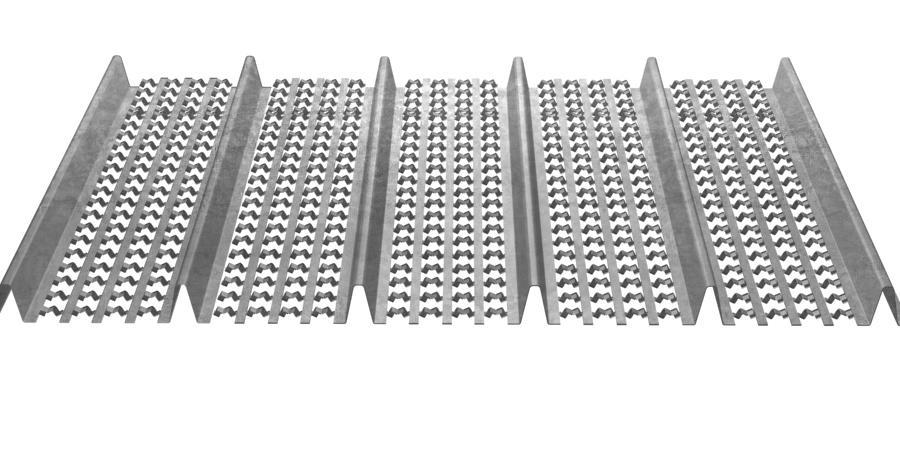

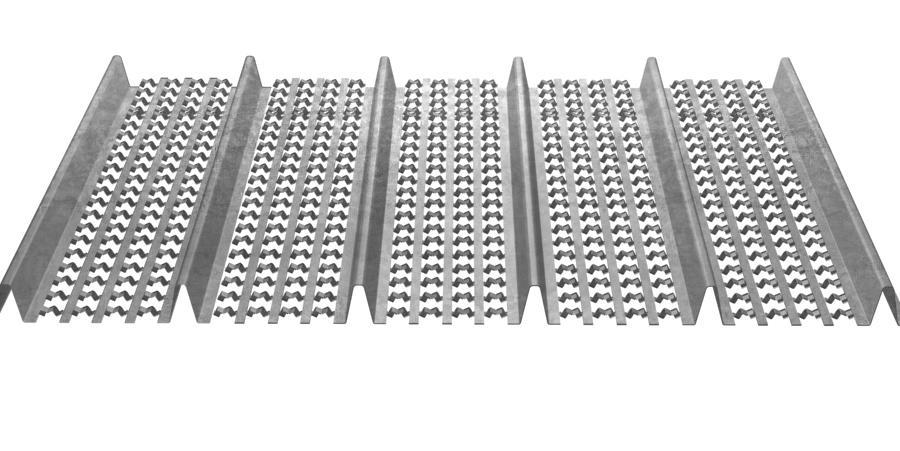

High Rib Lath

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

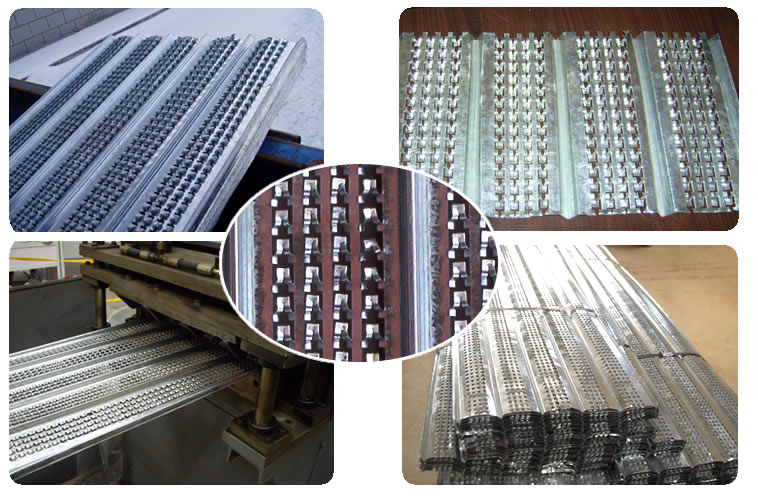

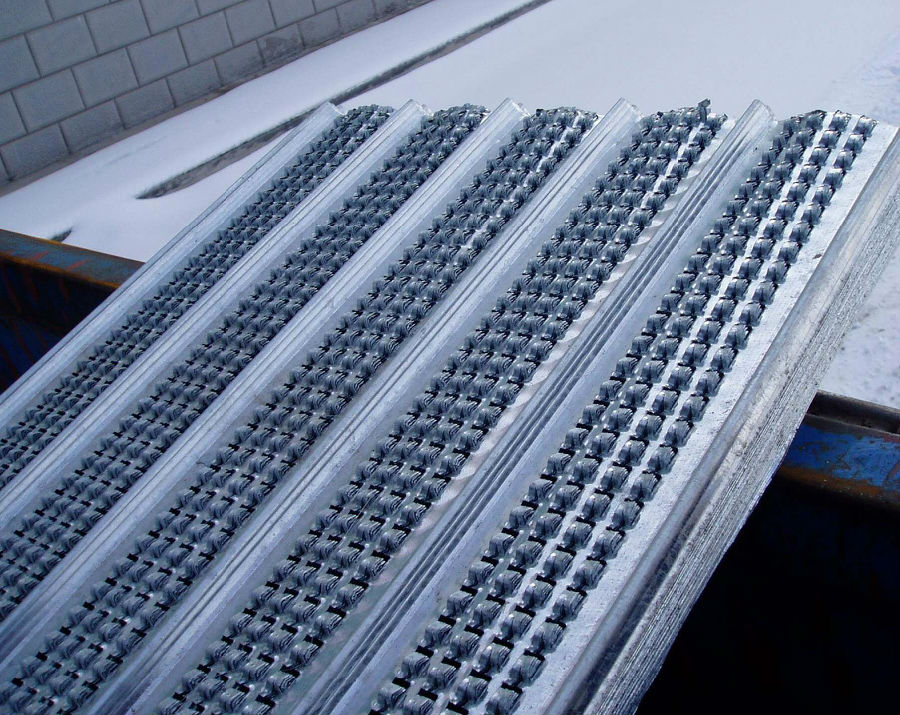

High Ribbed Formwork is made from hot dipped galvanized steel sheets. The mesh and ribs are formed on machines which first cut and press the mesh and then roll form the ribs. At the same time the material is stretched to form an expanded mesh.

Matal Rib Lath/High Rib Lath

Concreting mould mesh

Material: hot-dipped galvanized steel sheet

Thickness: 0.1-0.5mm

Size: 450x2000mm

ISO9001 certific

Feature: Because of its meshes and U patterns, it has better anti-stress capability and forming flexibility than normal metal lath. This product has excellent engineering quality, construction security

Application:

1).Construction formwork mesh has very good engineering quality and construction security;

2).Construction formwork mesh as the concrete permanent assembly

free sheet is much convenient for engineering design and processing;

3).Construction formwork mesh is widely used in tunnels,bridges and valve system and so on

to make the process of construction much more fast and stable.

Specification:

Thickness (mm) | Weight (kg) | Width (mm) | Length (mm) | Area (m2) |

0.2 | 1.70 | 445 | 2200 | 0.99 |

0.25 | 2.10 | 445 | 2200 | 0.99 |

0.30 | 2.60 | 445 | 2200 | 0.99 |

0.35 | 3.00 | 445 | 2200 | 0.99 |

0.40 | 3.40 | 450 | 2200 | 0.99 |

0.45 | 3.80 | 450 | 2200 | 0.99 |

0.50 | 4.20 | 450 | 2200 | 0.99 |

0.55 | 4.60 | 450 | 2200 | 0.99 |

0.60 | 5.00 | 450 | 2200 | 0.99 |

- Q: How is steel wire mesh used in reinforcement of parking structures?

- Steel wire mesh is used in the reinforcement of parking structures by providing additional strength and stability. It is typically installed within the concrete to prevent cracking and increase the overall load-bearing capacity of the structure. The mesh helps distribute the weight and forces evenly, minimizing the risk of structural failure and enhancing durability.

- Q: Does steel wire mesh rust?

- Yes, steel wire mesh can rust over time when exposed to moisture and oxygen.

- Q: Can steel wire mesh be used for pest control?

- Steel wire mesh is a reliable option for pest control. It is frequently utilized to prevent pests from infiltrating specific areas or structures. Known for its resilience and robustness, steel wire mesh effectively acts as a barrier against rodents, birds, and insects. Its applications include covering openings in windows, doors, vents, and other potential entry points for pests. Moreover, steel wire mesh can be employed to construct fences or enclosures, effectively keeping pests away from gardens, yards, or other outdoor spaces. Due to its small openings, it hinders pests from passing through while still allowing for adequate ventilation. In conclusion, steel wire mesh is a versatile and widely used solution for both residential and commercial pest control needs.

- Q: Is steel wire mesh suitable for outdoor applications?

- Indeed, steel wire mesh proves to be highly appropriate for outdoor applications. Renowned for its robustness and sturdiness, steel wire mesh emerges as an exceptional alternative for outdoor utilization. It possesses the ability to endure adverse weather conditions, including strong gusts of wind, torrential rainfall, and extreme temperatures, without succumbing to any harm or corrosion. Not only that, steel wire mesh exhibits resistance against bothersome pests, rodents, and insects, rendering it an ideal choice for outdoor perimeters, enclosures, and protective barriers. Moreover, steel wire mesh can undergo galvanization or be coated with materials such as PVC, thereby fortifying its anti-corrosion properties and extending its lifespan, thereby rendering it even more suitable for outdoor applications.

- Q: Can steel wire mesh be used for waste water treatment?

- Yes, steel wire mesh can be used for waste water treatment. Steel wire mesh is often used as a filter medium in various water treatment processes, including waste water treatment. It is commonly employed in applications such as screening out large debris or particles from the waste water, preventing them from entering the treatment system. The steel wire mesh acts as a barrier, allowing water to pass through while capturing solid waste. Additionally, steel wire mesh can also be used as a support structure for other filtration media, such as activated carbon or sand, enhancing the overall treatment efficiency. Overall, steel wire mesh is a versatile and durable material that can effectively contribute to waste water treatment processes.

- Q: How is steel wire mesh used in reinforcement of residential buildings?

- Steel wire mesh is a commonly utilized material in the reinforcement of residential buildings. Its purpose is to enhance the structural integrity and durability of concrete structures. Its usage is particularly prevalent in areas where concrete is susceptible to cracking or in situations that require additional strength. When constructing concrete slabs in residential buildings, one of the primary applications for steel wire mesh is evident. Placing the steel mesh in the center of the slab creates a reinforcement layer that evenly distributes the load and prevents cracking. This is especially important in areas with high foot traffic or where heavy items such as furniture or appliances will be positioned. The reinforcement of concrete walls is another vital use for steel wire mesh. Typically positioned parallel to the surface in the middle of the wall, it provides additional strength and prevents cracking. This is particularly crucial in areas prone to seismic activity or where soil conditions may cause shifting or settling of the walls. Furthermore, steel wire mesh is employed in the reinforcement of residential building foundations. By placing the mesh below the concrete footing, it aids in evenly distributing the load and preventing cracking or settling of the foundation. This is especially important in areas with unstable soil or where the water table is high. Overall, steel wire mesh plays a crucial role in enhancing the strength and preventing cracking in residential buildings. It contributes to the longevity and stability of the structure, ensuring its ability to withstand external forces such as heavy loads, seismic activity, and soil movements.

- Q: Can steel wire mesh be used for creating mesh containers?

- Yes, steel wire mesh can be used for creating mesh containers. Steel wire mesh is durable, strong, and has excellent load-bearing capabilities, making it suitable for constructing containers that can hold and transport various items securely. Additionally, the open design of mesh containers allows for visibility and proper ventilation, making them versatile and commonly used in industries such as logistics, warehousing, and agriculture.

- Q: How is steel wire mesh used in geotechnical engineering?

- Various applications in geotechnical engineering commonly utilize steel wire mesh. Soil stabilization is one primary use where the mesh reinforces weak or loose soil, preventing slope instability and erosion. This reinforcement is achieved through horizontal or vertical installation of the mesh, creating a strong barrier that retains the soil's shape and prevents movement. Steel wire mesh is also employed in the construction of retaining walls and embankments. These structures are built to withhold soil or rock masses, preventing landslides and collapses. The mesh is installed within or behind the retaining wall, reinforcing it and distributing the forces exerted by the soil or rock mass evenly, reducing the risk of failure. Additionally, erosion control systems utilize steel wire mesh. It is installed on slopes or riverbanks to protect the soil from erosion caused by water or wind. Acting as a barrier, the mesh prevents the washing away or blowing off of soil particles. By stabilizing the soil and reducing erosion, steel wire mesh maintains the integrity of the landscape and prevents environmental damage. Furthermore, rockfall protection in geotechnical engineering utilizes steel wire mesh. In areas prone to rockfall, such as mountainous regions or highways, the mesh is installed to catch and contain falling rocks. Anchored to the slope or cliff face, it creates a protective barrier, preventing rocks from reaching the ground and posing a hazard to people or structures below. In summary, steel wire mesh serves a crucial role in geotechnical engineering, providing reinforcement, stability, and protection to various structures and landscapes. Its durability and versatility make it the preferred choice for applications requiring strength and resistance to environmental factors.

- Q: How is steel wire mesh used in reinforcement of schools?

- To enhance the structural integrity and ensure safety, schools commonly employ steel wire mesh for reinforcement purposes. This mesh is primarily utilized in concrete applications like floor slabs, walls, and columns. By incorporating the wire mesh into the concrete, it imparts additional strength and prevents cracking or breaking under load. When constructing school buildings, areas that experience higher stress or require added support, such as staircases, balconies, and heavily trafficked zones, typically have steel wire mesh installed. This evenly distributes the load across the structure, thereby minimizing the risk of structural failure. Moreover, steel wire mesh finds application in reinforcing concrete pavements, patios, and outdoor play areas within the school premises. It fortifies these surfaces, making them more durable and resistant to wear and tear, especially in areas where heavy equipment or vehicles may be used. Additionally, steel wire mesh can serve as a substitute for traditional brickwork or masonry when constructing walls. This cost-effective solution offers enhanced flexibility, reduced construction time, and improved earthquake resistance. It proves especially advantageous in regions prone to seismic activity, where ensuring the safety of school buildings is of utmost importance. In summary, the use of steel wire mesh in school reinforcement guarantees robust and long-lasting structures capable of withstanding the demands of daily use. It plays a pivotal role in upholding the safety and structural integrity of school buildings, ensuring a secure environment for students, teachers, and staff.

- Q: How does the panel thickness affect the rigidity of steel wire mesh?

- The rigidity of a steel wire mesh is directly impacted by its panel thickness. Generally, thinner panels exhibit less rigidity compared to thicker ones. This is primarily due to the fact that thicker panels contain more material, resulting in enhanced structural stability and resistance against bending or deformation. When a steel wire mesh possesses a thicker panel, it provides greater support and strength, rendering it more suitable for applications that demand higher levels of rigidity. Thicker panels can withstand larger forces and stresses without experiencing significant deformation. Consequently, they are commonly utilized in heavy-duty applications like industrial fencing, security barriers, and structural reinforcements. Conversely, thinner panels offer more flexibility and can easily bend or deform under external forces. This makes them suitable for applications where a certain degree of flexibility is required, such as architectural designs, decorative elements, or lightweight partitions. However, it is important to note that thinner panels may be more vulnerable to damage or breakage if subjected to excessive loads or impacts. To summarize, the rigidity of steel wire mesh is directly influenced by its panel thickness. Thicker panels provide increased rigidity, strength, and resistance against deformation, making them ideal for heavy-duty applications. On the other hand, thinner panels offer flexibility and are suitable for applications where a certain level of bending or deformation is desired.

Send your message to us

High Rib Lath

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches